Novel processing and coating dryer for polrvinyl chloride/polyvinylidene chloride medicinal composite sheet and use method thereof

A polyvinylidene chloride, polyvinyl chloride technology, applied in chemical instruments and methods, coatings, devices for coating liquids on surfaces, etc. high degree issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

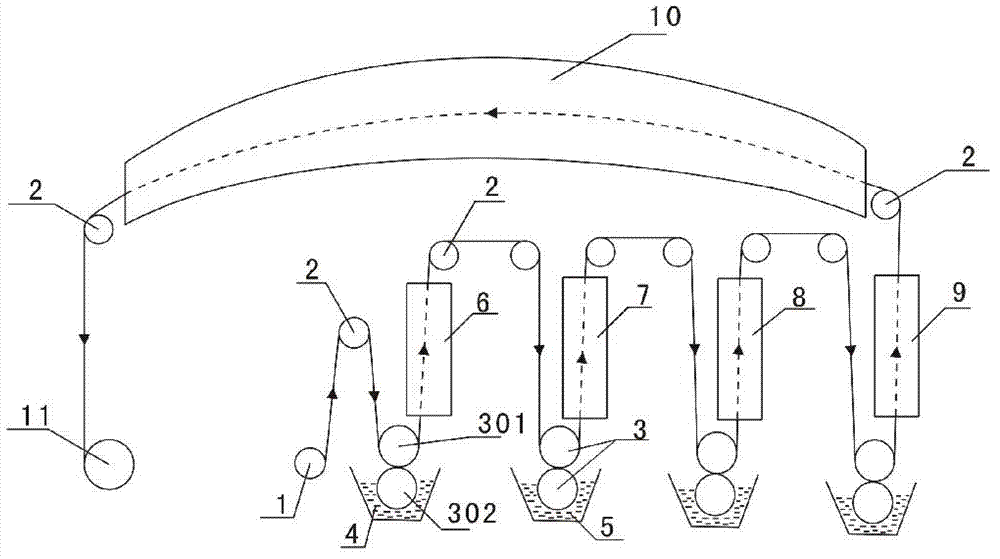

[0017] Such as figure 1 As shown, a new type of polyvinyl chloride / polyvinylidene chloride pharmaceutical composite sheet processing and coating dryer includes a first vertical drying tunnel 6, a second vertical drying tunnel 7, a third vertical drying tunnel 8, The fourth vertical drying tunnel 9, the arched horizontal drying tunnel 10, the adhesive tank 4, the PVDC emulsion tank 5, the coating roller 3 and the direction changing roller 2, and the coating roller 3 is composed of upper transmission rollers 301 and The bottom rubber roller 302 is composed; the arched horizontal drying tunnel 10 is set above several vertical drying tunnels, the adhesive tank 4 is located under the first vertical drying tunnel 6, and the PVDC emulsion tank 5 is located in the second vertical drying tunnel 7. Below the third vertical drying tunnel 8 and the fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com