Preparation method of super capacitor electrode material (nickel oxide)

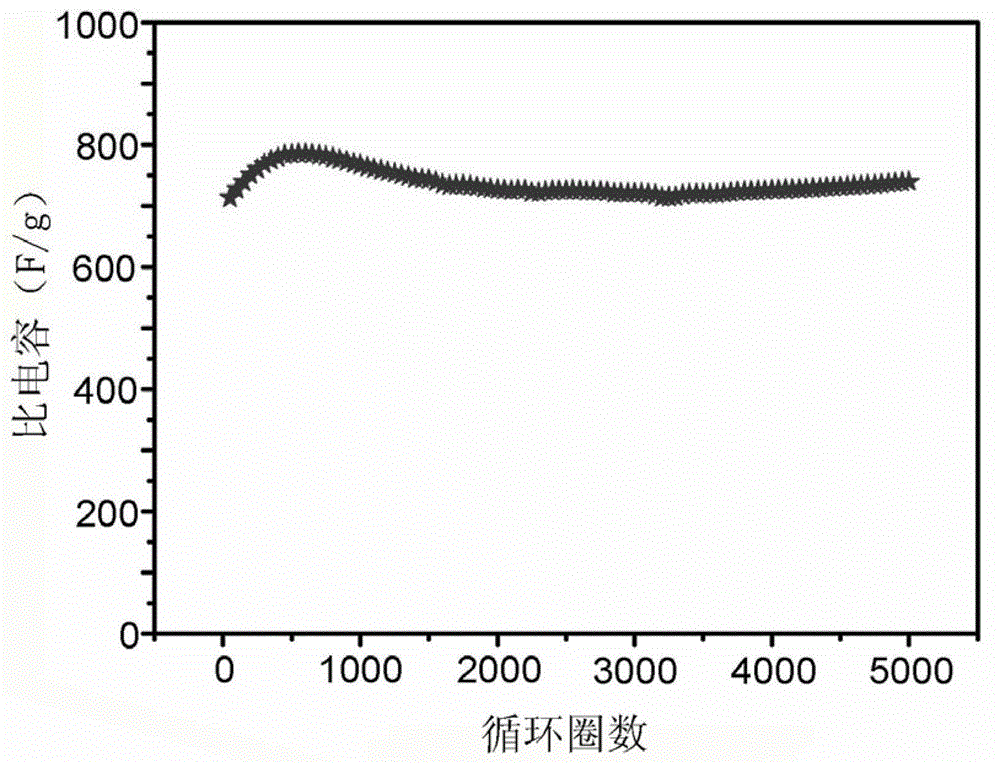

A technology for supercapacitors and electrode materials, applied in nickel oxide/nickel hydroxide and other directions, can solve the problems of high cost and complicated preparation process, and achieve the effects of low cost, simple preparation method and good electrochemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 3.4mmol and 0.5g of polyvinylpyrrolidone (PVP) were dissolved in methanol and water, and stirred to prepare a mixed solution; wherein, the volumes of methanol and water were 43ml and 5ml respectively;

[0026] (2) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle to maintain a filling degree of 80%, put the hydrothermal reaction kettle into a blast drying oven, react at 180°C for 6 hours, and then cool Reactor to room temperature.

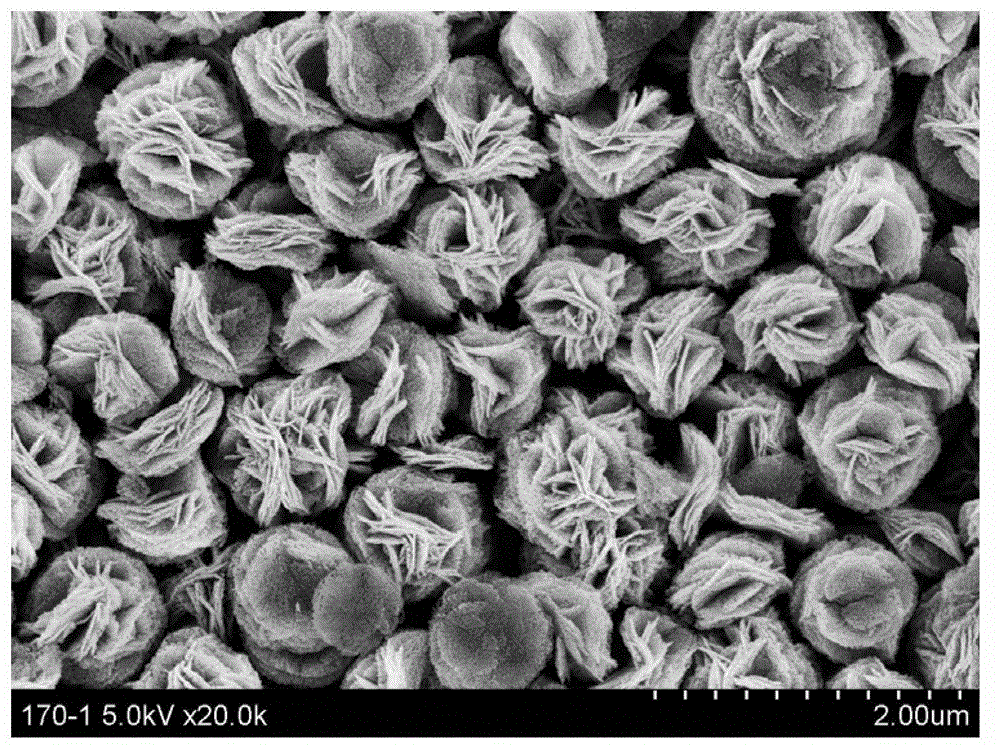

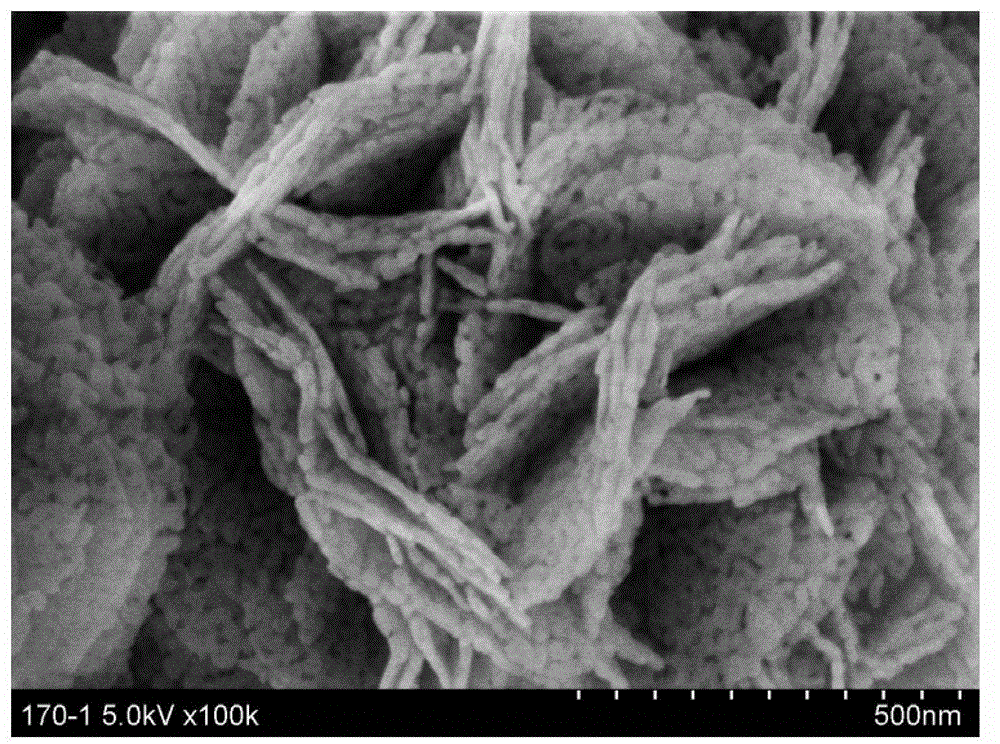

[0027] (3) The product obtained by centrifugation was washed with deionized water and ethanol solvent respectively, and dried; the dried sample was placed in a muffle furnace and calcined at 450°C for 40 minutes; the final black sample obtained was supercapacitor oxidation Nickel electrode material.

Embodiment 2

[0029] (1) Weigh the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 (0) 2mmol and 0.05g of polyvinylpyrrolidone (PVP) were dissolved in methanol and water, and stirred to prepare a mixed solution; wherein, the volumes of methanol and water were 41ml and 7ml respectively;

[0030] (2) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, keep the filling degree of 80%, put the hydrothermal reaction kettle into a blast drying oven, react at 150°C for 24 hours, and then cool Reactor to room temperature.

[0031] (3) The product obtained by centrifugation was washed with deionized water and ethanol solvent respectively, and dried; the dried sample was placed in a muffle furnace and calcined at 450°C for 40 minutes; the final black sample obtained was supercapacitor oxidation Nickel electrode material.

Embodiment 3

[0033] (1) Weigh the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 (0) 4mmol and 1g of polyvinylpyrrolidone (PVP) were dissolved in methanol and water, and stirred to prepare a mixed solution; wherein, the volumes of methanol and water were 40ml and 8ml respectively;

[0034] (2) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, keep the filling degree of 80%, put the hydrothermal reaction kettle into a blast drying oven, react at 180°C for 3 hours, and then cool Reactor to room temperature.

[0035] (3) The product obtained by centrifugation was washed with deionized water and ethanol solvent respectively, and dried; the dried sample was placed in a muffle furnace and calcined at 450°C for 40 minutes; the final black sample obtained was supercapacitor oxidation Nickel electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com