Lead-free glass material and preparation method thereof

A technology of lead-free glass and glass materials, which is applied in the field of lead-free glass materials and its preparation, can solve the problems of harmfulness to humans and organisms, failure of electrode patterns to meet precision requirements, non-elastic deformation of screens, etc., and achieve easy realization, Easy to promote and use, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

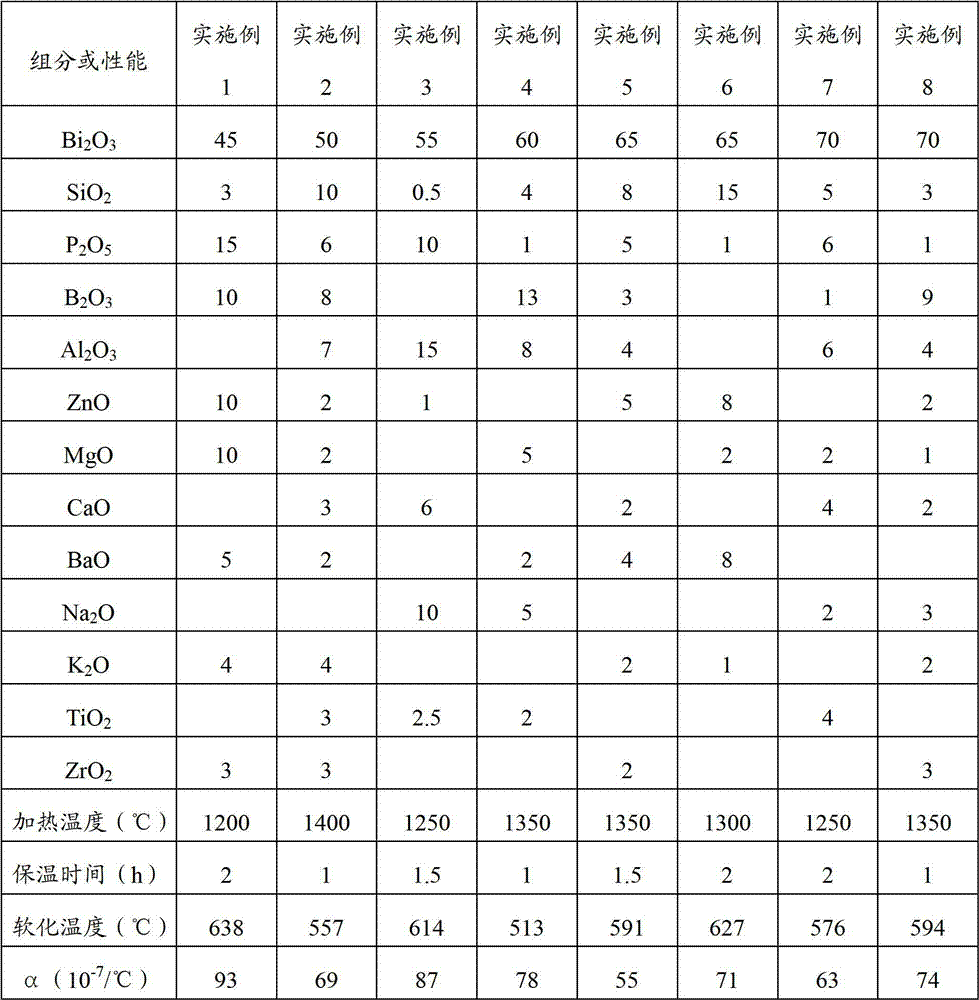

Examples

preparation example Construction

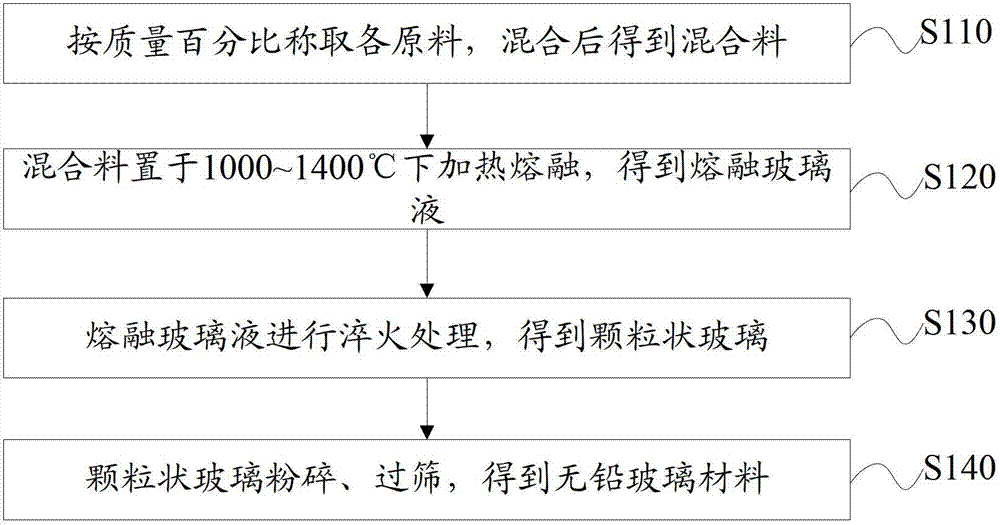

[0030] In addition, if figure 1 As shown, this embodiment also provides a method for preparing a lead-free glass material, including the following steps:

[0031] Step S110, weighing each raw material component according to the following weight percentage: Bi 2 o 3 : 20~80%, SiO 2 : 0~40%, P 2 o 5 : 0.1~30%, B 2 o 3 : 0~30%, Al 2 o 3 : 0~20%, ZnO: 0~20%, MgO: 0~10%, CaO: 0~10%, BaO: 0~30%, Na 2 O: 0~15%, K 2 O: 0~15%, ZrO 2 : 0~15% and TiO 2 : 0~15%, mixed to get the mixture.

[0032] In step S120, the mixture is heated and melted at 1000-1400° C. to obtain molten glass.

[0033] Step S130, quenching the molten glass to obtain granular glass.

[0034] In this embodiment, the quenching treatment is water quenching with deionized water.

[0035] In step S140, the granular glass is ball-milled and sieved to obtain a glass material.

[0036] In this embodiment, the molecular sieve used in the sieving process has a mesh size of 200 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com