Continuous production method of 2-MeTHF (2-methyltetrahydrofuran)

A technology of methyltetrahydrofuran and production method, applied in the direction of organic chemistry and the like, can solve the problems affecting the industrialization of process technology, high risk, high cost, and reduce the use of highly toxic and high-cost catalysts, low risk, and impurities. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

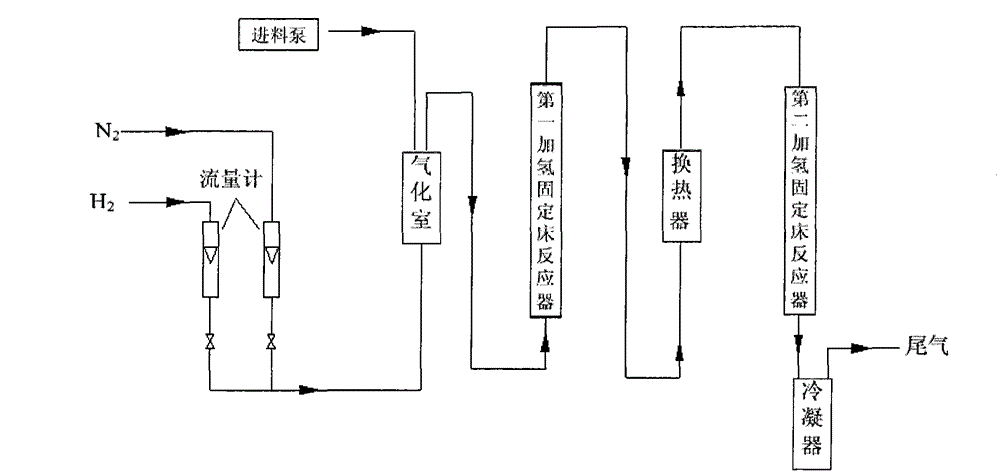

[0022] According to a typical implementation of the present invention, the continuous production method of 2-methyltetrahydrofuran comprises the following steps: input gasified furfural and hydrogen into the first reaction zone, and a catalytic hydrogenation reaction occurs; The gas is input into the second reaction zone for secondary catalytic hydrogenation reaction; and the gas output from the second reaction zone is condensed to obtain 2-methyltetrahydrofuran; wherein, the first reaction zone is filled with a catalyst for aldehyde group reduction , the second reaction zone is packed with a catalyst for aromatic saturation hydrogenation.

[0023] The present invention adopts a low-toxic, cheap and easy-to-obtain catalyst to produce high-purity 2-MeTHF from furfural through gas-phase continuous reaction under low pressure or ambient pressure, which changes the traditional production of 2-MeTHF that requires high pressure, high investment and Highly hazardous process, reducing...

Embodiment 1

[0046] Reaction equipment: gasification chamber, first hydrogenation fixed bed reactor (DN25 white steel pipe, length 50cm), heat exchanger, second hydrogenation fixed bed reactor (DN25 white steel pipe, length 50cm), condenser.

[0047] reaction process:

[0048] (1) 100 g of copper-based catalyst (commodity number TG-45, from Shanghai Xunkai) was filled in the first hydrogenation fixed-bed reactor, and the height of the catalyst bed after filling was 15 cm. Temperature measuring points are respectively set on the upper part and the lower part of the catalyst bed of the first fixed bed reactor. In the second fixed-bed reactor, about 150 g (wet weight 240 g) of Raney Ni catalyst (product number RTH-2123E, from Dalian Tonghua) was packed by wet packing, and the catalyst bed was about 15 cm high after packing. Temperature measuring points are respectively set on the upper part and the lower part of the catalyst bed of the second fixed bed reactor.

[0049] (2) The gas flows th...

Embodiment 2-3

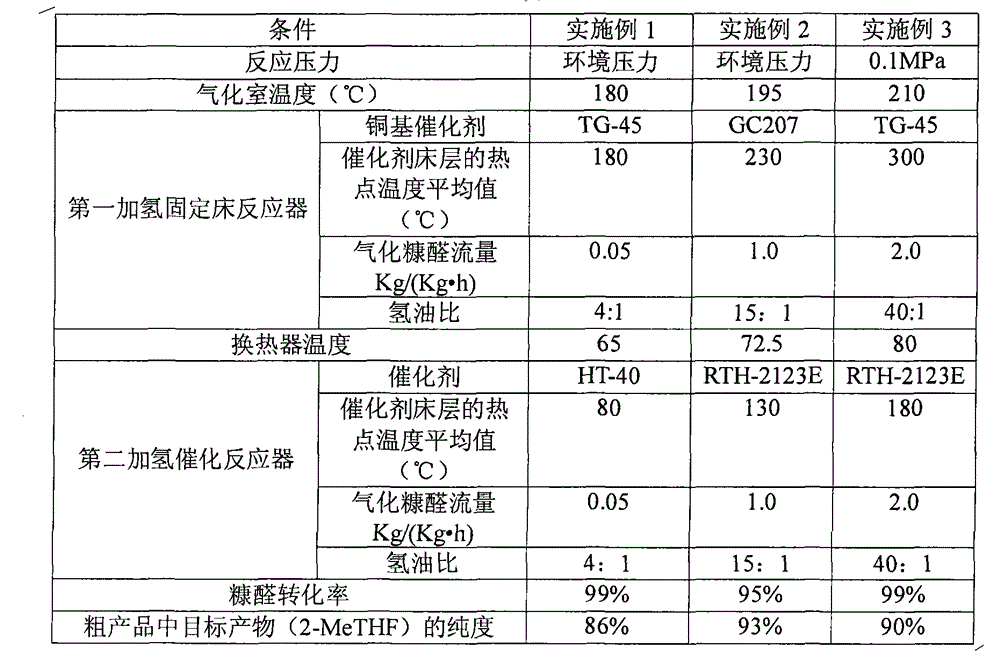

[0052] The operation steps are basically the same as in Example 1, except for the catalyst type, reaction temperature and flow rate, etc., see Table 1 for details.

[0053] Wherein the reaction process of embodiment 1-3 is all under low pressure or environment pressure condition, and concrete condition and result are shown in Table 1.

[0054] Table 1

[0055]

[0056] Note: The hydrogen-to-oil ratio is the molar ratio of hydrogen flow to gasified furfural flow.

[0057]As can be seen from the data of Examples 1-3, the catalyst of the present invention has been adopted to realize the continuous production of 2-MeTHF by furfural under low pressure or ambient pressure by gas-phase reaction, which has changed the traditional production of 2-MeTHF that requires high pressure, high The high-input and high-risk process improves upon the use of highly toxic or high-cost catalysts in the prior art due to the use of low-toxicity and cheap and readily available catalysts. In additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com