Method for depositing coating

A deposition method and coating technology, applied in the field of coating deposition, can solve the problem of inability to precisely control the color of the coating, and achieve the effect of improving the anti-corrosion ability and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

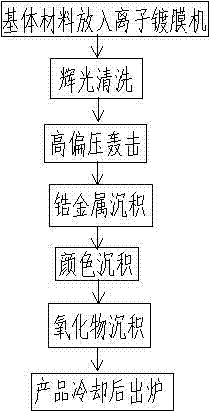

[0034] As the physical vapor deposition method of the first embodiment of the present invention, it specifically includes the following steps:

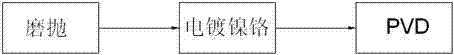

[0035] Base material pretreatment steps:

[0036] The present invention selects copper alloy as the base material, and first grinds and polishes the copper alloy through a grinding wheel, the grain size number of the grinding wheel is 180#, and then uses a cloth wheel to clear the light to obtain a base material with a surface finish Ra of 0.04;

[0037] Electroplating the copper alloy after the finish treatment to obtain a copper alloy covered with an electroplating layer, the electroplating layer is a nickel layer and a chromium layer, wherein the thickness of the nickel layer is 14 um, and the thickness of the chromium layer is 0.25 um.

[0038] PVD steps:

[0039] Soaking: Soak the pre-treated copper alloy base material in alcohol, take it out and wipe it with pure cotton cloth, and then hang it in a special hanger.

[0040]...

Embodiment 2

[0047] As the physical vapor deposition method of the 2nd embodiment of the present invention, specifically comprise the following steps:

[0048] Base material pretreatment steps:

[0049] The present invention selects copper alloy as the base material, and first grinds and polishes the copper alloy through a grinding wheel, the grain size number of the grinding wheel is 180#, and then adopts a cloth wheel to clear the light to obtain a base material with a surface roughness Ra of 0.08;

[0050] Electroplating the copper alloy after the finish treatment to obtain a copper alloy covered with an electroplating layer, the electroplating layer is a nickel layer and a chromium layer, wherein the thickness of the nickel layer is 16um, and the thickness of the chromium layer is 0.6um.

[0051] PVD steps:

[0052] Soaking: Soak the pre-treated copper alloy base material in alcohol, take it out and wipe it with pure cotton cloth, and then hang it in a special hanger.

[0053] ...

Embodiment 3

[0060] As the physical vapor deposition method of the 3rd embodiment of the present invention, specifically comprise the following steps:

[0061] Base material pretreatment steps:

[0062] The present invention selects copper alloy as the base material, and first grinds and polishes the copper alloy through a grinding wheel, the grain size of the grinding wheel is 400#, and then uses a cloth wheel to clear the light to obtain a base material with a surface roughness Ra of 0.06;

[0063] Electroplating the copper alloy after the smoothing treatment to obtain a copper alloy covered with an electroplating layer, the electroplating layer is a nickel layer and a chromium layer, wherein the thickness of the nickel layer is 18um, and the thickness of the chromium layer is 1um.

[0064] PVD steps:

[0065] Soaking: Soak the pre-treated copper alloy base material in alcohol, take it out and wipe it with pure cotton cloth, and then hang it in a special hanger.

[0066] Glow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com