Preparation method of low-acid-value phosphorus-containing reactive flame-retardant polyol

A reactive flame retardant and low acid value technology, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of bubbles, affecting the mechanical properties of products, and not suitable for polyurethane materials and other problems, to achieve the effect of convenient post-processing, improved flame retardant performance, and simple experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

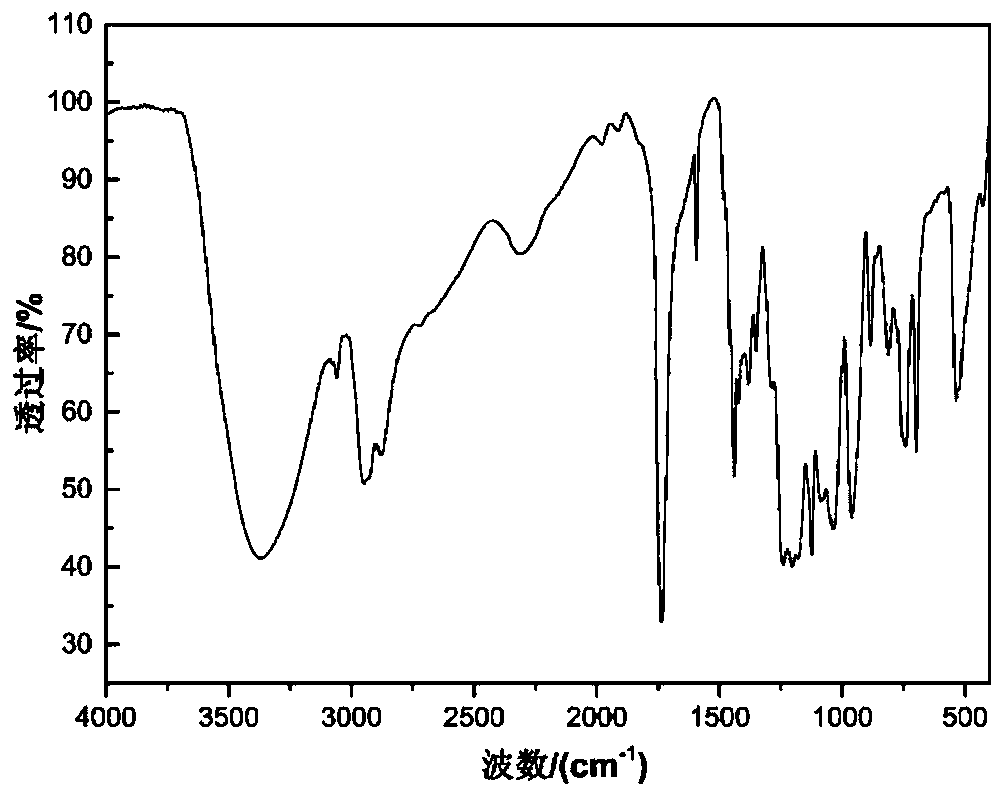

[0028] The preparation method of the described low-acid value phosphorus-containing reactive flame-retardant polyol consists of the following steps:

[0029] (1) Add 30g of 2-carboxyethylphenylphosphinic acid and 43.5g of ethylene glycol into a three-necked flask, then add 0.073g of antimony trioxide and 100μL of tetrabutyl titanate, raise the temperature to 100°C, and turn on the mechanical Stir to dissolve 2-carboxyethylphenylphosphinic acid completely. Under the protection of argon, perform esterification reaction at 100°C for 3h, then continue to heat up, and react at 160°C, 180°C and 200°C for 1.5h and 1h respectively and 1h, lower the temperature to 185°C, react under reduced pressure for 2h, and finally vacuum-dry the obtained product at 80°C to obtain an esterified intermediate with an acid value of 50mgKOH / g.

[0030] (2) Add 17.5931g of the esterification intermediate into the Erlenmeyer flask, and dissolve it completely with 30mL of acetonitrile, then add 6.49g of a...

Embodiment 2

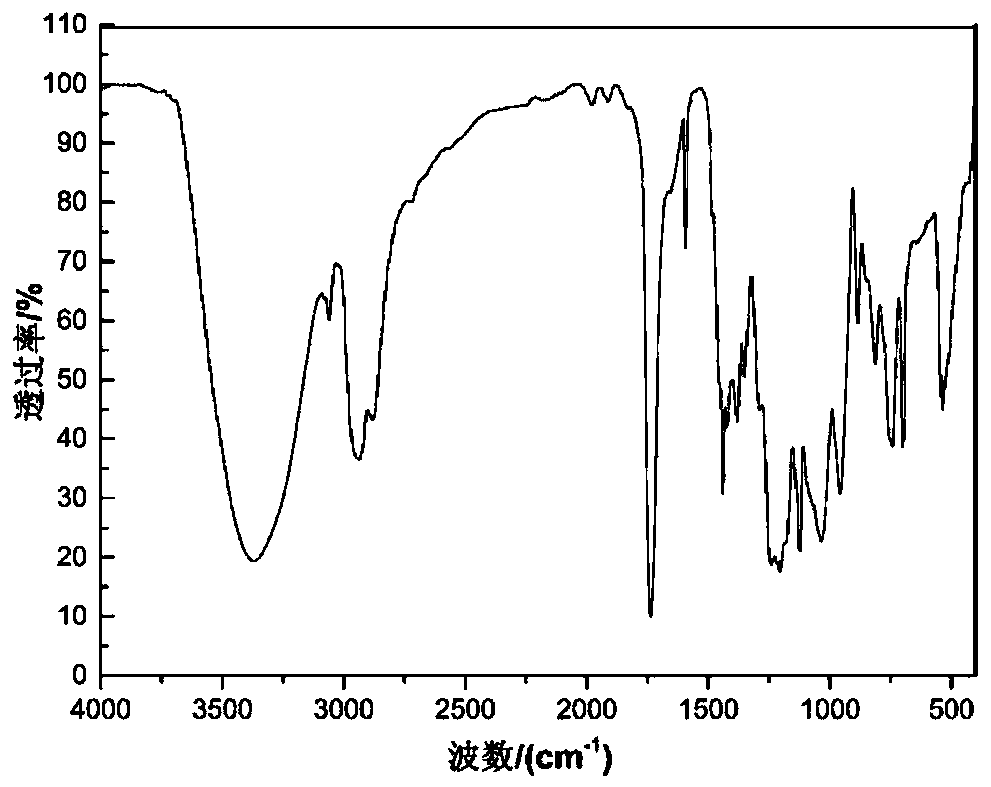

[0032] The preparation method of the described low-acid value phosphorus-containing reactive flame-retardant polyol consists of the following steps:

[0033] (1) Add 30g of 2-carboxyethylphenylphosphinic acid and 26.1g of ethylene glycol into a three-necked flask, then add 0.056g of antimony trioxide and 100μL of tetrabutyl titanate, raise the temperature to 100°C, and turn on the mechanical Stir to completely dissolve 2-carboxyethylphenylphosphinic acid, react at 100°C for 3h under the protection of argon, then continue to heat up, and react at 160°C, 180°C, and 200°C for 1.5h, 1h, and 1h respectively , lower the temperature to 185°C, react under reduced pressure for 2h, and finally vacuum-dry the obtained product at 80°C to obtain an esterified intermediate with an acid value of 70mgKOH / g.

[0034] (2) Add 17.5931g of the esterification intermediate into the Erlenmeyer flask, and dissolve it completely with 30mL of acetonitrile, then add 6.49g of anhydrous potassium carbonat...

Embodiment 3

[0036] The preparation method of the described low-acid value phosphorus-containing reactive flame-retardant polyol consists of the following steps:

[0037] (1) The preparation method of the esterification intermediate is as in Example 2.

[0038] (2) 17.5931g of esterification intermediate was added to the conical flask, and it was completely dissolved with 30mL of N,N-dimethylformamide, then 6.49g of anhydrous potassium carbonate was added, and finally 3mL of methyl iodide was added, and Under the airtight condition of 20° C. protected from light, the reaction was carried out with magnetic stirring for 10 hours. After the reaction is complete, remove potassium carbonate by suction filtration, add copper powder to the filtrate, and distill off excess iodomethane and N,N-dimethylformamide under reduced pressure. After vacuum drying, the acid value of the product is 2.10 mgKOH / g, and the hydroxyl value is 174 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com