Lotus-leaf slimming teabag and production method thereof

A technology for making tea bags and lotus leaves is applied in the field of new lotus leaf slimming tea bags and preparing the lotus leaf slimming tea bags. The effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

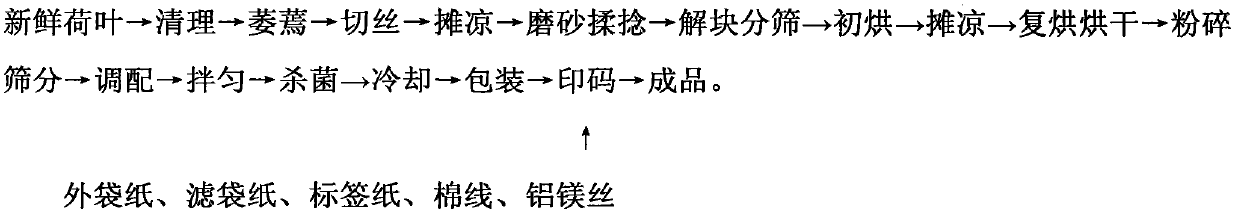

Method used

Image

Examples

Embodiment 1

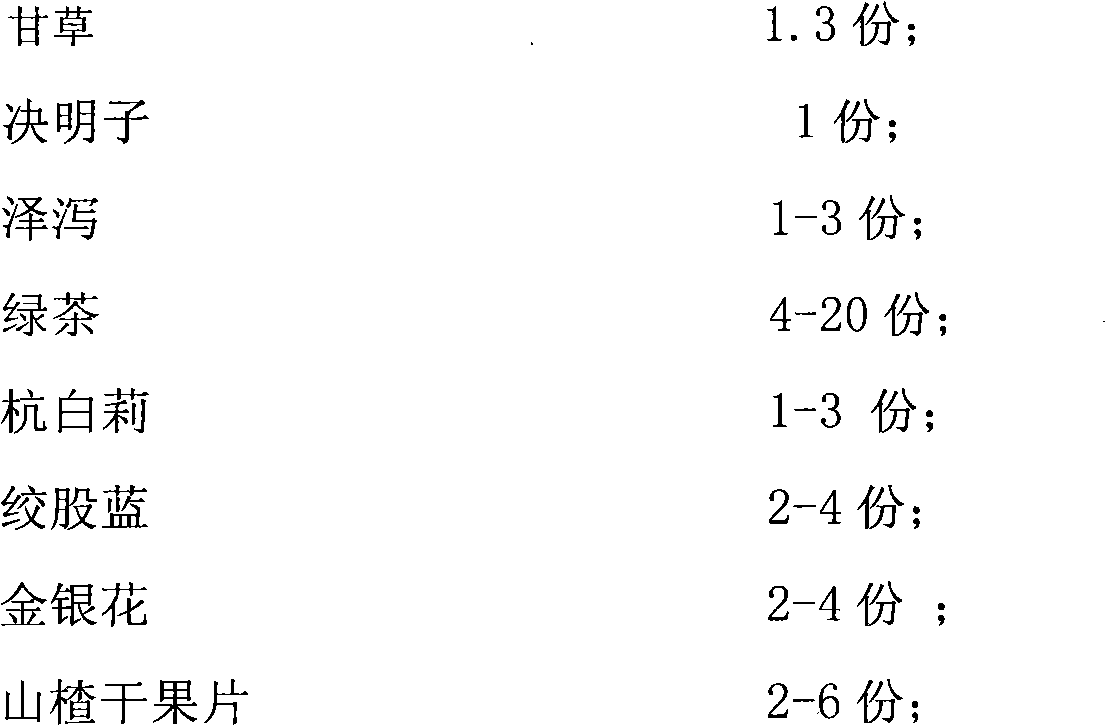

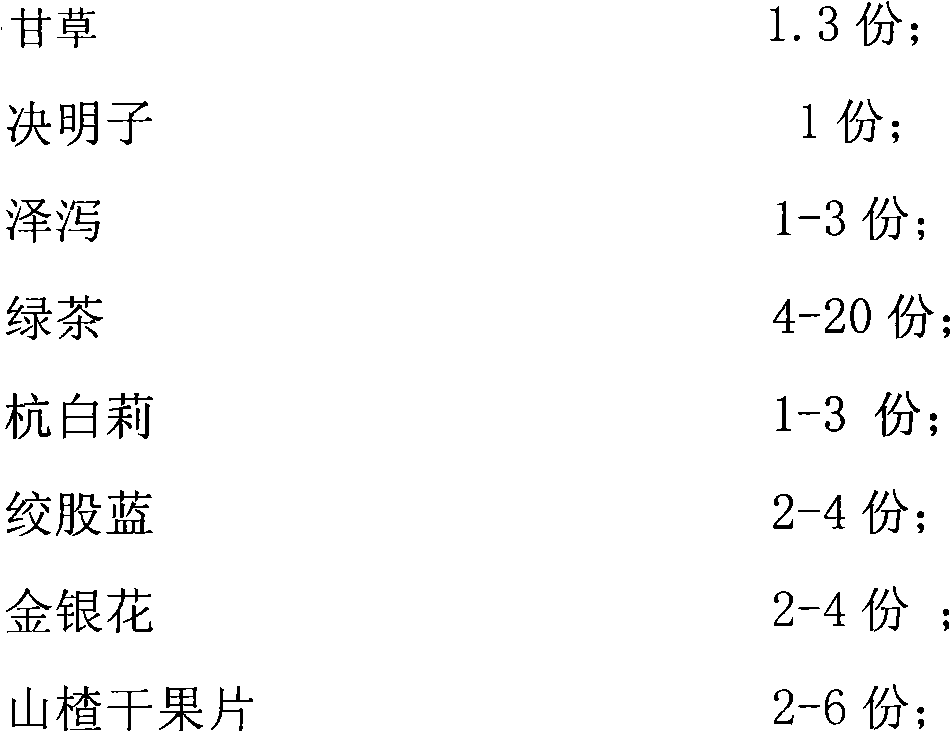

[0028] Take 180kg of fresh lotus leaves (the water content of fresh lotus leaves is 80%) and spread them with a thickness of 4cm-5cm, and turn them over every 2 hours; the spread time is 6-8h. Until the leaf quality becomes soft, the leaf color changes from bright green to dark green; cut into 1-2cm lotus leaf strips through a shredder knife; Produced by the machinery factory, the same below), the greening temperature is 60-85 ° C, and the greening time is 3 minutes; kneading in the tea rolling machine (model: YS7501, produced by Furunwang Machinery Equipment Co., Ltd., the same below) for 20 minutes to 30 minutes, in the Vacuum dryer (model: 6CIIW series vacuum dryer, produced by Zhejiang Fuyang Tea Machinery Factory, the same below), vacuum degree 0.05-0.08MPa, temperature 30-60℃), drying (drying) time 10min, after crushing 100 mesh analytical sieves to obtain lotus leaf powder with a water content of 10%; additionally get licorice 1.3kg, cassia seed 1kg, Alisma 1kg, green t...

Embodiment 2

[0030] With reference to the equipment selection and technical parameters of Example 1, get 180kg of fresh lotus leaves (the moisture content of fresh lotus leaves is 80%) and spread them with a thickness of 4cm-5cm, turn over once every 2 hours; spread time 6h-8h. Until the leaves become soft, and the leaf color changes from bright green to dark green; cut into 1-2cm lotus leaf strips with a shredder knife; in a drum continuous killing machine (temperature 60-85°C), the killing time is 3min; knead in the tea leaves Knead in the machine for 20min to 30min, in a vacuum dryer (vacuum degree 0.05-0.08MPa, temperature 30-60°C, drying time 10min; when the water content is 10%, crush and sieve. Take another licorice 1.3, Cassia seed 1kg, Alisma 3kg, green tea 4kg, Hang Baili 1kg, Gynostemma 2kg, honeysuckle 2kg and hawthorn dried fruit slices 2kg are mixed, after crushing, pass through a 100-mesh analytical sieve; then mix with the crushed and sieved lotus leaf powder to obtain a mix...

Embodiment 3

[0032] With reference to the equipment selection and technical parameters of Example 1, weigh 180kg of fresh lotus leaves (moisture content is 80%) and spread them with a thickness of 4cm-5cm, turn over once every 2 hours; spread time 6h-8h. Until the leaves become soft, and the leaf color changes from bright green to dark green; cut into 1-2cm lotus leaf strips with a shredder knife; in a drum continuous killing machine (temperature 60-85°C), the killing time is 3min; knead the tea leaves Knead in the machine for 20min to 30min, dry in a vacuum dryer (vacuum degree 0.05-0.08MPa, temperature 30-60℃), and dry for 10min; when the water content is 10%, crush and sieve (pass through 100 mesh after crushing) Analytical sieve ;). Take another 1.3kg of licorice, 2kg of cassia seeds, 3kg of Alisma, 4kg of green tea, 1kg of Hangbaili, 2kg of Gynostemma pentaphyllum, 2kg of honeysuckle and 2kg of dried hawthorn slices, mix them, and pass through a 100-mesh analytical sieve after crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com