Method for constructing blood-compatible coating with degradable polyester

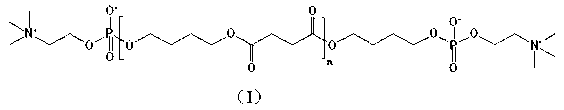

A technology of blood compatibility and degradation of polyester, applied in the direction of coating, can solve the problems of affecting the performance of phosphorylcholine polymers and restricting the wide use of materials, achieving good anti-platelet adhesion, simple operation and wide variety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A 2 mg / mL PBS-PC chloroform solution was prepared, and the coverslip was immersed in the solution and lifted slowly to obtain a uniform coating with an average thickness of 190 nm. Place in air at room temperature for 1 day to completely evaporate the solvent as much as possible. The dynamic contact angle (DCA) was measured, and the average advancing angle was 112°, and the average receding angle was 21°.

Embodiment 2

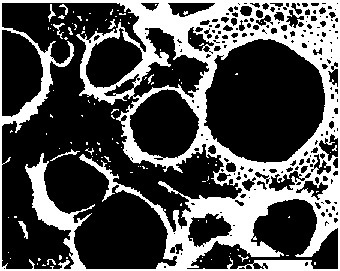

[0026] Use a micropipette to draw a PBS-PC chloroform solution with a concentration of 2 mg / mL and coat it on the surface of a dry and clean cover glass, and coat evenly to obtain a coating with an average thickness of 184 nm. Place it in the air at room temperature for 1 day to completely evaporate the solvent, and then measure the dynamic contact angle. The average advancing angle is 112° and the average receding angle is 21°. The surface morphology of the coating and the results of adhered platelets are as follows: figure 1 As shown, the platelets have more adhesion on the surface of the polymer coating, and the blood compatibility is poor.

Embodiment 3

[0028] Use a micropipette to draw a PBS-PC chloroform solution with a concentration of 2 mg / mL and coat it on the surface of a dry and clean cover glass, and coat evenly to obtain a coating with an average thickness of 184 nm. Place it in air at room temperature for 1 day to completely evaporate the solvent, then heat it in water at 90 °C for 30 min for hydrophilic treatment, and then measure the dynamic contact angle after cooling to room temperature naturally. The average advancing angle is 92° and the average receding angle is 8°. The coating surface morphology and adhered platelet results after hydrophilic treatment are as follows: figure 2 As shown, there is no platelet adhesion on the surface of the polymer coating with the membrane structure imitating the outer layer of cells, the coating platelet adhesion is reduced by more than 90%, and the blood compatibility is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com