Reduction method for preparing superfine cobalt powder by hydrazine hydrate

A technology of ultra-fine cobalt powder and hydrazine hydrate, which is applied in the field of preparing ultra-fine cobalt powder by reduction of hydrazine hydrate, can solve the problems of high cost, low purity of cobalt powder, low efficiency, etc. Barrier lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

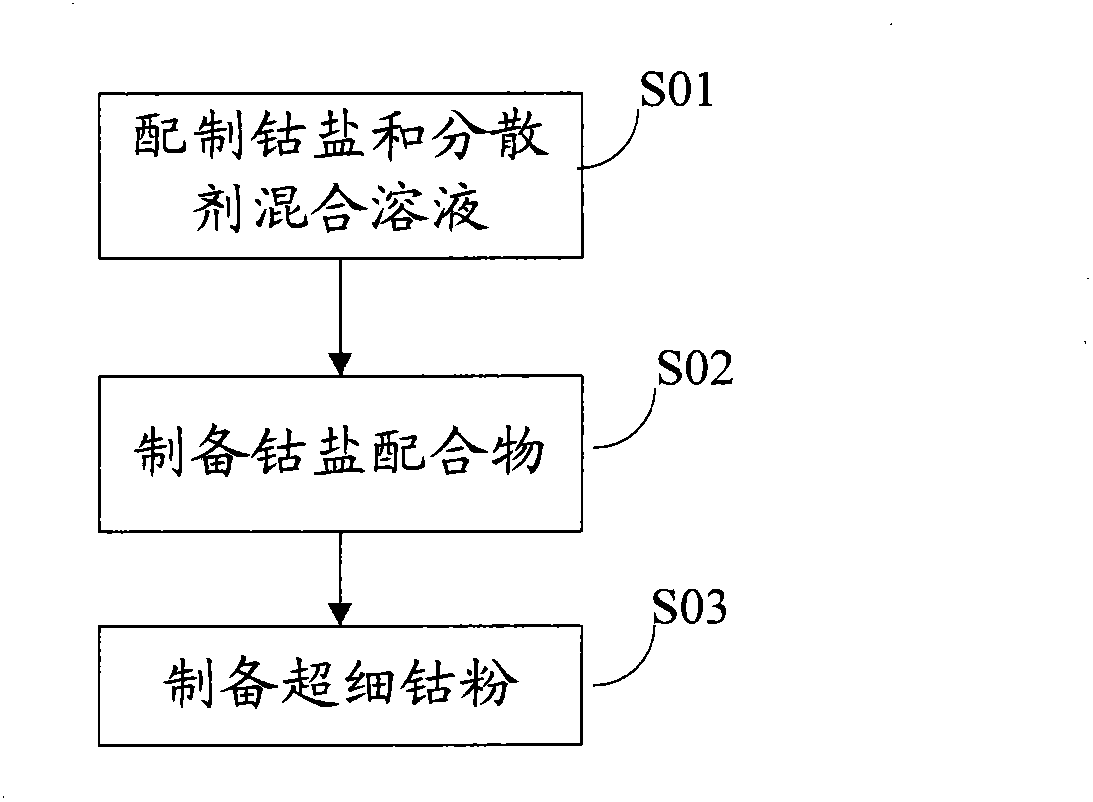

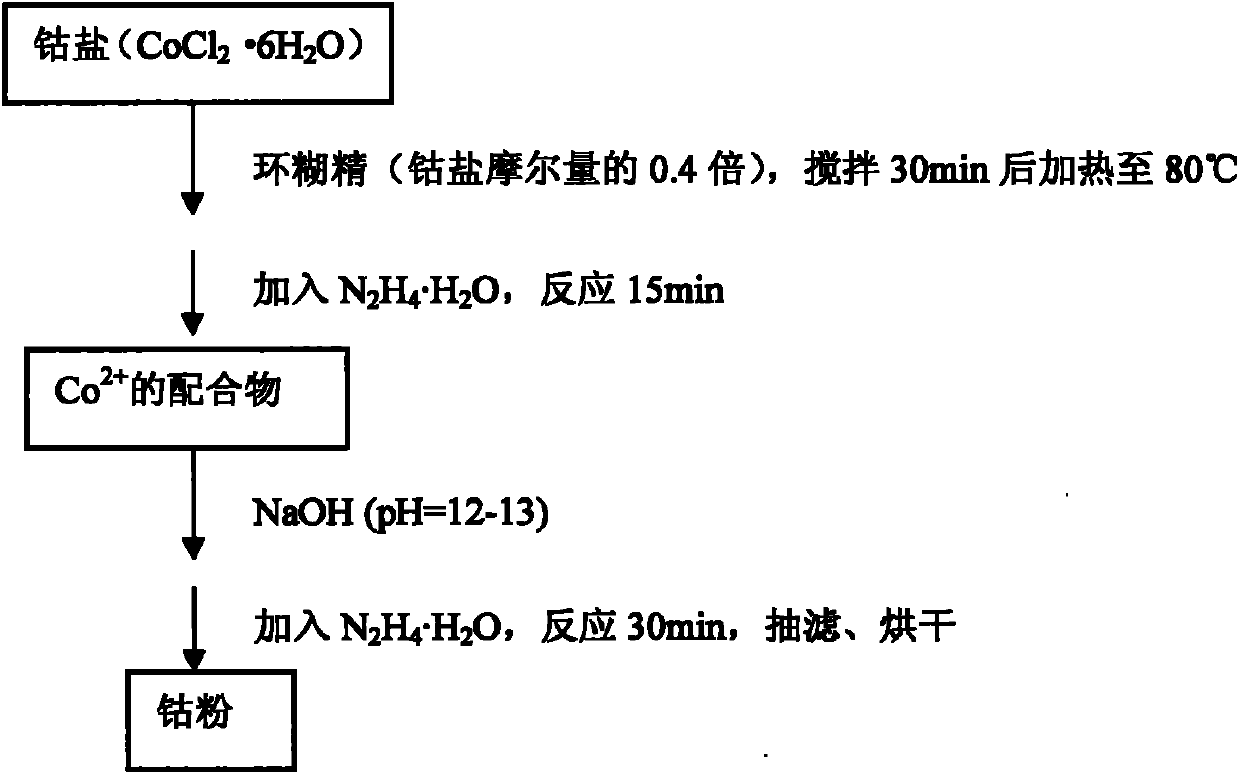

[0030] see figure 2 , figure 2 Show the flow chart of the method for preparing ultrafine cobalt powder by reduction of hydrazine monohydrate in the embodiment of the present invention, including the following steps:

[0031] i, preparation of cobalt salt and dispersant mixed solution:

[0032] Prepare a cobalt salt with a concentration of 0.8 mol / L, add cyclodextrin to the cobalt salt solution, the molar weight of the cyclodextrin is 0.4 times the molar weight of cobalt ions, and stir for 30 minutes to obtain the first solution;

[0033] ii, preparation of cobalt salt complexes:

[0034] Adjust the temperature of the first solution to 80° C., add hydrazine hydrate with a weight percentage of 80%, and react for 15 minutes to obtain a second solution. The molar ratio of cobalt ions in the hydrazine hydrate and cobalt salt solution is 1.3:1;

[0035] iii. Preparation of cobalt powder

[0036] Adjust the pH value of the second solution to 12, add hydrazine hydrate so that th...

Embodiment 2

[0038] The method for preparing superfine cobalt powder by reduction of hydrazine hydrate in the embodiment of the present invention comprises the following steps:

[0039] i, preparation of cobalt salt and dispersant mixed solution:

[0040] Prepare a cobalt salt with a concentration of 0.9 mol / L, add sodium hypophosphite to the cobalt salt solution, the molar weight of the sodium hypophosphite is 0.45 times the molar weight of cobalt ions, and stir for 40 minutes to obtain the first solution;

[0041] ii, preparation of cobalt salt complexes:

[0042] Adjust the temperature of the first solution to 82° C., add hydrazine hydrate with a weight percentage of 80%, and react for 20 minutes to obtain a second solution. The molar ratio of cobalt ions in the hydrazine hydrate and cobalt salt solution is 1.4:1;

[0043] iii. Preparation of cobalt powder

[0044] Adjust the pH value of the second solution to 12.5, add hydrazine hydrate so that the total molar ratio of hydrazine hydrat...

Embodiment 3

[0046] The method for preparing superfine cobalt powder by reduction of hydrazine hydrate in the embodiment of the present invention comprises the following steps:

[0047] i, preparation of cobalt salt and dispersant mixed solution:

[0048] Prepare a cobalt salt with a concentration of 1.0 mol / L, add cyclodextrin to the cobalt salt solution, the molar weight of the cyclodextrin is 0.5 times the molar weight of cobalt ions, and stir for 50 minutes to obtain the first solution;

[0049] ii, preparation of cobalt salt complexes:

[0050] Adjust the temperature of the first solution to 85° C., add hydrazine hydrate with a weight percentage of 80%, and react for 20 minutes to obtain a second solution. The molar ratio of cobalt ions in the hydrazine hydrate and cobalt salt solution is 1.5:1;

[0051] iii. Preparation of cobalt powder

[0052] Adjust the pH value of the second solution to 13, add hydrazine hydrate so that the total molar ratio of hydrazine hydrate to the cobalt i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com