Lead-free high-frequency brazing method for deformed zinc alloy grafting structure

A plug-in structure and high-frequency brazing technology, which is applied to welding media, welding equipment, metal processing equipment, etc., can solve the problems that restrict the promotion and application of zinc-substituting copper products, the existence of pores and cracks, and the overall structure is easy to loosen, etc., to achieve High industrial utilization value, short liquefaction process, and the effect of improving labor conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

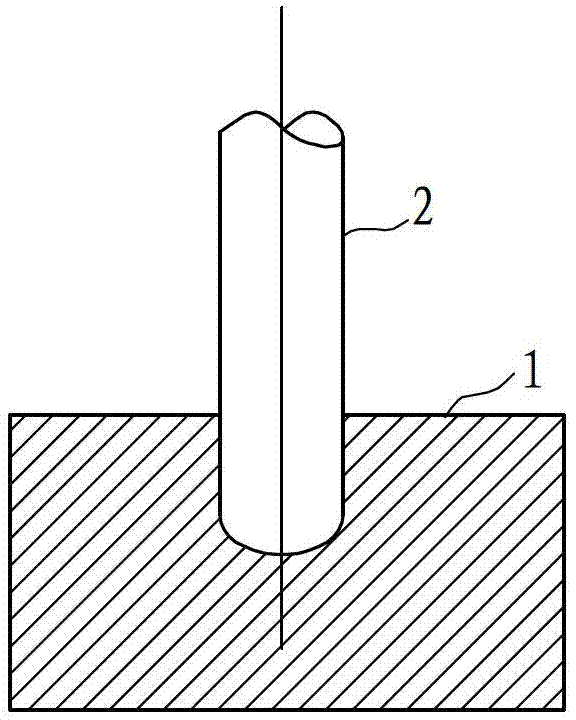

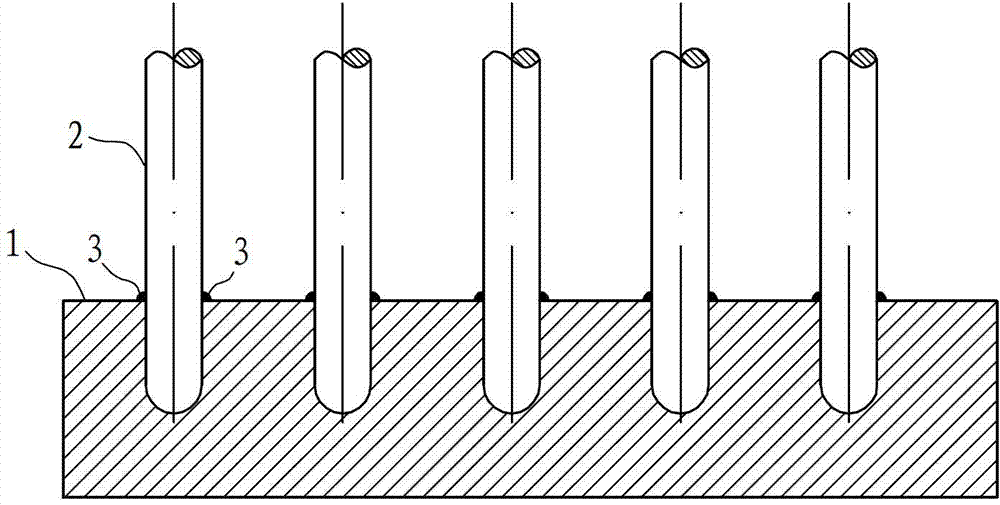

[0024] Example 1, such as figure 1 As shown, the deformed zinc alloy plug-in structure includes a zinc alloy plate 1 and a zinc alloy rod 2 inserted on the zinc alloy plate 1 . Such as figure 2 As shown, this embodiment is a lead-free high-frequency brazing process for deformed zinc alloy products with a rod-plate plug-in structure. The zinc alloy rods (φ3mm) and plates (80×6×12mm) are made of deformed zinc alloy (Zn-Al system). A. Pre-welding assembly process, including inspection process, first inspect the external dimensions of zinc alloy plate 1 and zinc alloy rod 2, focusing on the size of the hole on the zinc alloy plate; B. Pre-assembly process: use 280# for brazing parts Grinding with sandpaper, and then cleaning with acetone, the treated surface shall not be re-oxidized or re-contaminated; C. Assembly process: insert the zinc alloy rod into the hole of the zinc alloy plate, and insert it to the bottom without any inclination, and then insert the φ0. The 8mm Sn96.5...

Embodiment 2

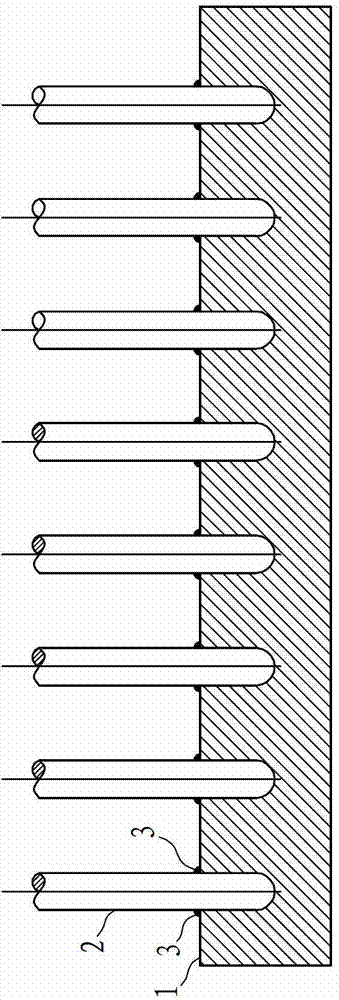

[0026] Example 2, such as image 3 As shown, this embodiment is a lead-free high-frequency brazing process for deformed zinc alloy products with a rod-plate plug-in structure. The rods (φ3mm) and plates (120×6×12mm) are made of deformed zinc alloy (Zn-Al system). A. Pre-welding assembly process, including inspection process, first inspect the external dimensions of the zinc alloy plate and rod, focusing on the size of the hole on the zinc alloy plate; B. Pre-assembly process: sand the brazed part, and then use acetone Cleaning, the treated surface shall not be re-oxidized or soiled; C. Assembly process: insert the zinc alloy rod into the hole, and insert it to the bottom without any inclination, and then insert the φ1.0mm Sn96.5Ag3.0Cu0.5 solder ring Set it on the part to be soldered, and apply YH-816 environment-friendly water-soluble flux (flux: manufacturer Ningbo Xihan Tin Solder Co., Ltd., batch number 2010-9-2) to the brazing seam; D. Welding process: use 60KW high fre...

Embodiment 3

[0028] Example 3, such as Figure 4 As shown, this embodiment is a lead-free high-frequency brazing process for deformed zinc alloy products with a rod-plate plug-in structure. The rods (φ3mm) and plates (150×6×12mm) are made of deformed zinc alloy (Zn-Al system). A. Pre-welding assembly process, including inspection process, first inspect the external dimensions of the zinc alloy plate and rod, focusing on the size of the hole on the zinc alloy plate; B. Pre-assembly process: sand the brazed part, and then use acetone Cleaning, the treated surface shall not be re-oxidized or soiled; C. Assembly process: insert the zinc alloy rod into the hole, and insert it to the bottom without any inclination, and then set the φ1.2mm Sn99Ag0.3Cu0.7 solder ring on the The part to be welded, and apply YH-816 environment-friendly water-soluble flux (flux: manufacturer Ningbo Xihan Tin Solder Co., Ltd., batch number 2010-9-2) to the brazing seam; D. Welding process: use 60KW high Frequency in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com