Method for modifying graphite felt material applied to electro-Fenton system

A graphite felt and Fenton technology, which is applied in the field of modification of electrocatalytic cathode materials, can solve the problems of poor surface hydrophilicity, poor electrochemical activity and low yield of graphite felt materials, and achieves increased reaction active sites, easy Promote the application, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in detail through the following embodiments in conjunction with the accompanying drawings.

[0015] (1) Modification method of graphite felt material

[0016] Soak the cut graphite felt material (5cm×2cm×0.5cm) in an acetone solution for degreasing treatment. The soaking time is 12 hours. After taking it out, it is ultrasonically cleaned several times in deionized water until the residual acetone is removed, and then the material is left to stand Air-dried and used as pretreated graphite felt for later use; immerse the pretreated graphite felt in 100mL of absolute ethanol, heat it in a water bath at a constant temperature of 60°C for 6h, and then place it in a muffle furnace for annealing at 150°C for 2h to obtain the described Modified graphite felt material.

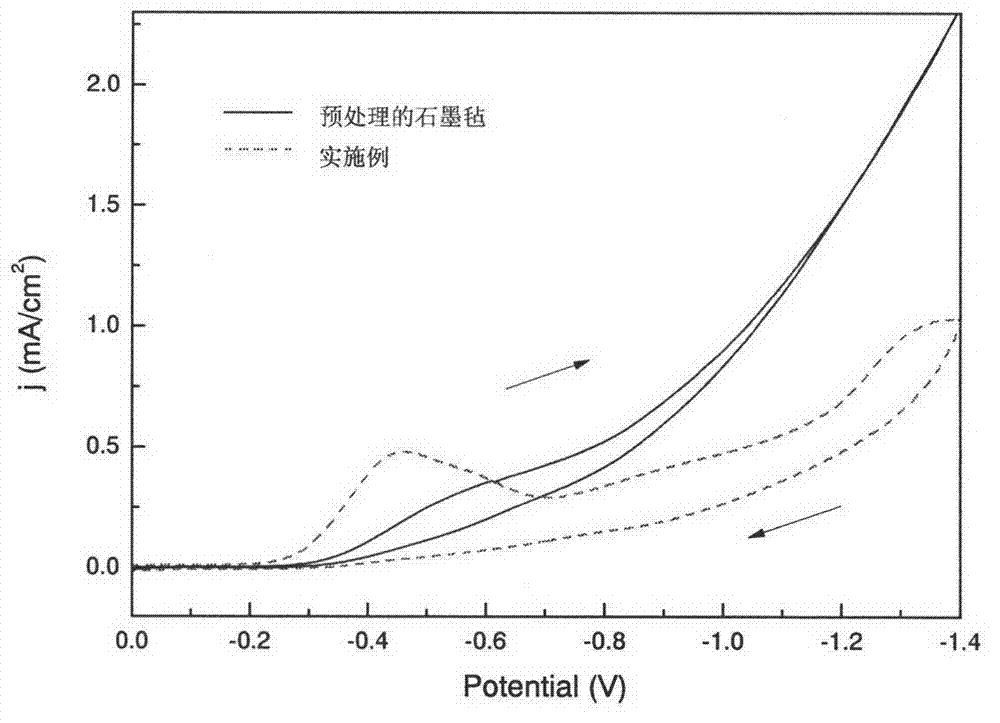

[0017] (2) The electrochemical performance of the product that this embodiment obtains

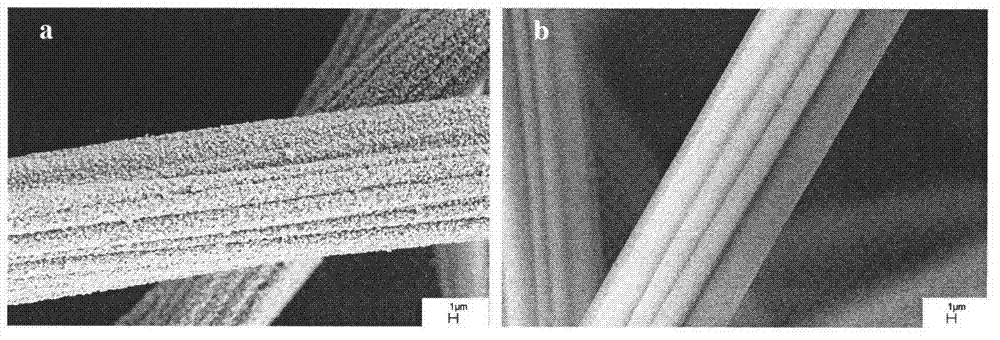

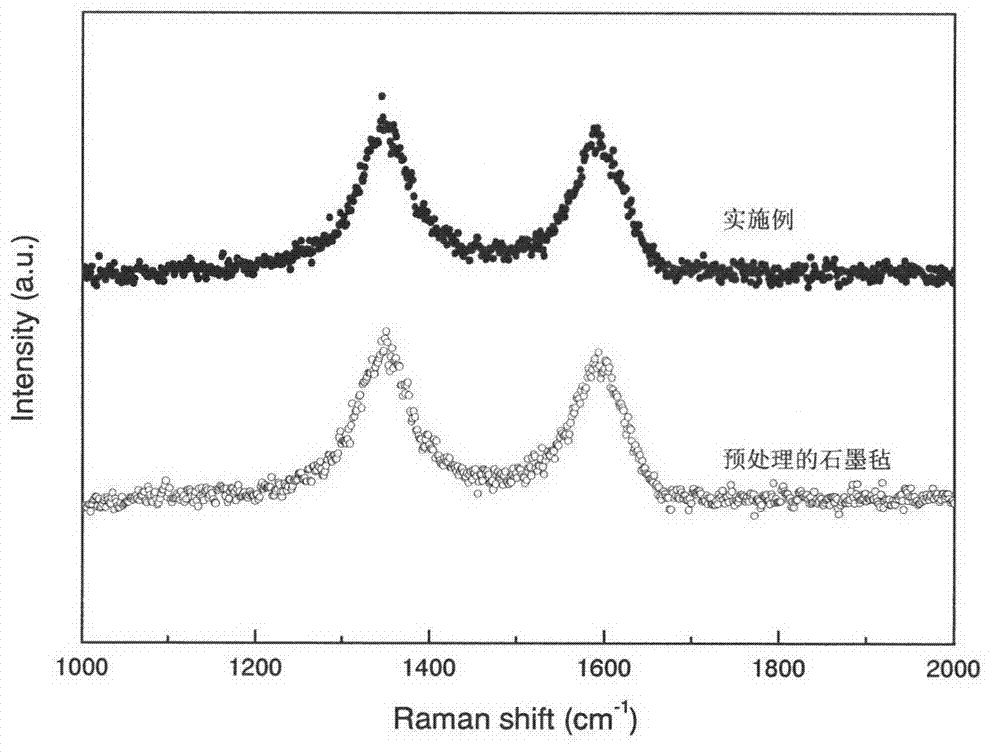

[0018] The SEM figure of the modified graphite felt material that this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com