Light-emitting diode (LED) light source module

A technology of LED light source and LED chip, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of inconsistent light attenuation speed of chips, undesired LED light source, and need to open mold for heat dissipation fins, so as to achieve light weight and structure. Simple and reasonable, the effect of improving the light output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

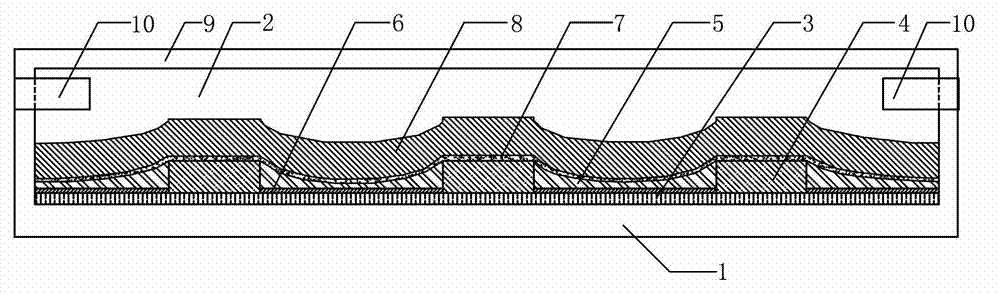

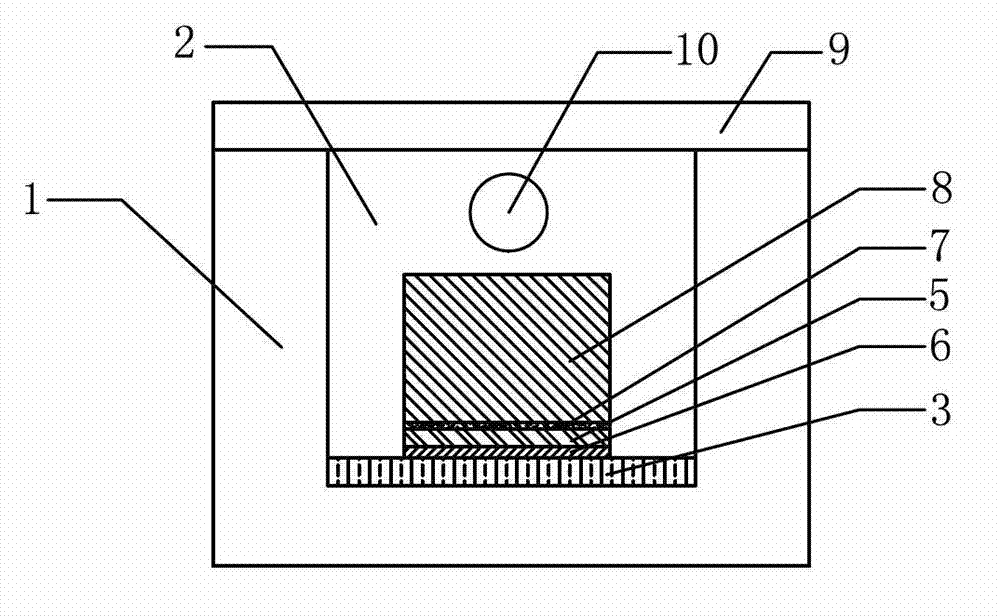

[0025] Figure 1-Figure 3 Embodiment 1 of the present invention is constituted.

[0026] refer to figure 1 and figure 2 , this embodiment includes a substrate 1, a groove 2 opened on the substrate 1, and a conductive layer 3 packaged in the groove 2, and three LED chips 4 and four photosensitive units 5 are installed on the conductive layer 3, so The LED chips 4 and the photosensitive units 5 are alternately arranged; an insulating layer 6 is arranged between each photosensitive unit 5 and the conductive layer 3, and a reflective layer 7 and The heat dissipation layer 8 , a circuit for electrically connecting the LED chips 4 is arranged on the bottom of the groove 2 .

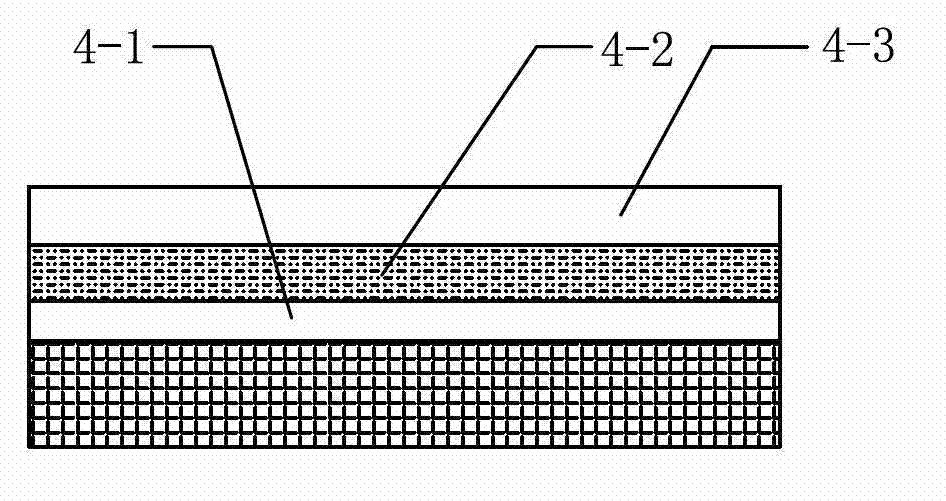

[0027] refer to image 3 , the LED chip 4 is sequentially coated with a first silica gel layer 4-1, a fluorescent layer 4-2 and a second silica gel layer 4-3 from the light-emitting surface, and the second silica gel layer 4-3 is in the shape of a film.

[0028] In this embodiment, a transparent material ...

specific Embodiment 2

[0034] The main features of this embodiment are: the transparent material layer 9 is made of glass, and the second silica gel layer 4-3 of the LED chip 4 is in the shape of a convex lens or a microlens array. All the other are with specific embodiment 1.

specific Embodiment 3

[0035] The main feature of this embodiment is that four or more LED chips 4 and five or more photosensitive units 5 are mounted on the conductive layer 3 . All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com