Bipolar plate for vanadium battery and preparation method for bipolar plate

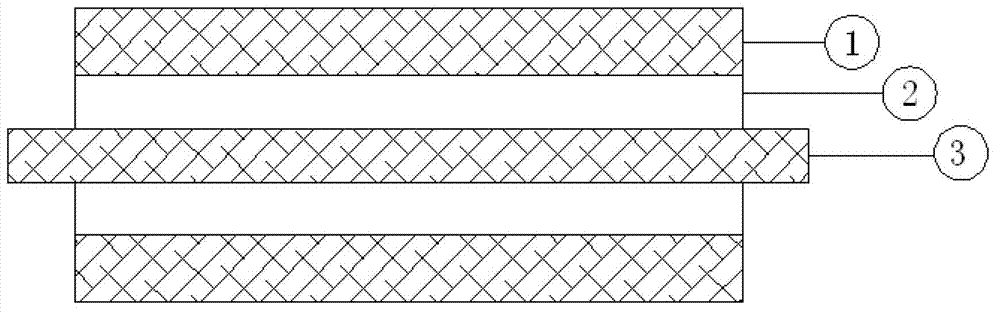

A bipolar plate and vanadium battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of high contact resistance and high resistivity of composite bipolar plates, and achieve good contact, good viscosity, and high conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take graphite felt electrode (specification: 560mm×width 320mm×thickness 5mm, bulk density is 0.10g / cm 3 ) and polyethylene resin powder (PE) 20g, deionized water 50mL, sonicate in the ultrasonic tank for 5h, take it out and put it in the oven at 90°C until the water evaporates, take it out as the skeleton layer, and fill the polyethylene resin powder in the graphite felt In the electrode, polyethylene resin powder accounts for 50% of the volume of the graphite felt electrode. Then take 10g of conductive carbon black, 5g of carbon fiber powder, and 15g of polyethylene resin powder and place them in a high-mixer at a stirring speed of 800 rpm for 20 minutes to make a conductive agent. Then put the conductive agent on the skeleton layer, and put graphite felt on the upper and lower surfaces for hot-pressing. The hot-pressing temperature is 180°C, the hot-pressing time is 20min, and the pressure is 1MPa to obtain a new type of bipolar plate for vanadium batteries.

[0027...

Embodiment 2

[0029] Take the graphite felt electrode (specification: length 560mm×width 320mm×thickness 6mm, bulk density is 0.15g / cm 3 ) and polypropylene resin powder (PP) 20g, deionized water 40mL, ultrasonic treatment in the ultrasonic pool for 30min, after taking it out, put it in the oven at 90°C until the water evaporates, take it out as the skeleton layer, and fill the polypropylene resin powder in the graphite felt In the electrode, the polypropylene resin powder accounts for 60% of the volume of the graphite felt electrode. Then take 15g of conductive carbon black, 5g of carbon fiber powder, and 25g of polypropylene powder and place them in a high-mixer at a stirring speed of 600 rpm for 20 minutes to make a conductive agent. Then put the conductive agent on the skeleton layer, and put graphite felt on the upper and lower surfaces for hot pressing. The hot pressing temperature is 190°C, the hot pressing time is 30min, and the pressure is 0.3MPa to obtain a new type of bipolar pla...

Embodiment 3

[0032] Take graphite felt electrode (specification: 560mm×width 320mm×thickness 5mm, bulk density is 0.05g / cm 3 ) and acrylic resin powder (PA) 20g, deionized water 50mL, sonicate in the ultrasonic tank for 5h, take it out and put it in the oven at 90°C until the water evaporates, take it out as the skeleton layer, and fill the acrylic resin powder in the graphite felt electrode , acrylic resin powder accounted for 30% of the graphite felt electrode volume. Then take 15g of conductive carbon black and 15g of acrylic resin powder and place it in a high mixer at a stirring speed of 800 rpm for 20 minutes to make a conductive agent. Then put the conductive agent on the skeleton layer, and put graphite felt on the upper and lower surfaces for hot-pressing. The hot-pressing temperature is 180°C, the hot-pressing time is 20min, and the pressure is 1MPa to obtain a new type of bipolar plate for vanadium batteries.

[0033] In this embodiment, the volume resistivity of the prepared c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com