Photoresist stripper composition

A technology of stripping agent and composition, applied in optics, photomechanical equipment, photosensitive material processing, etc., can solve the problems of manufacturing cost and time increase, and achieve excellent stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

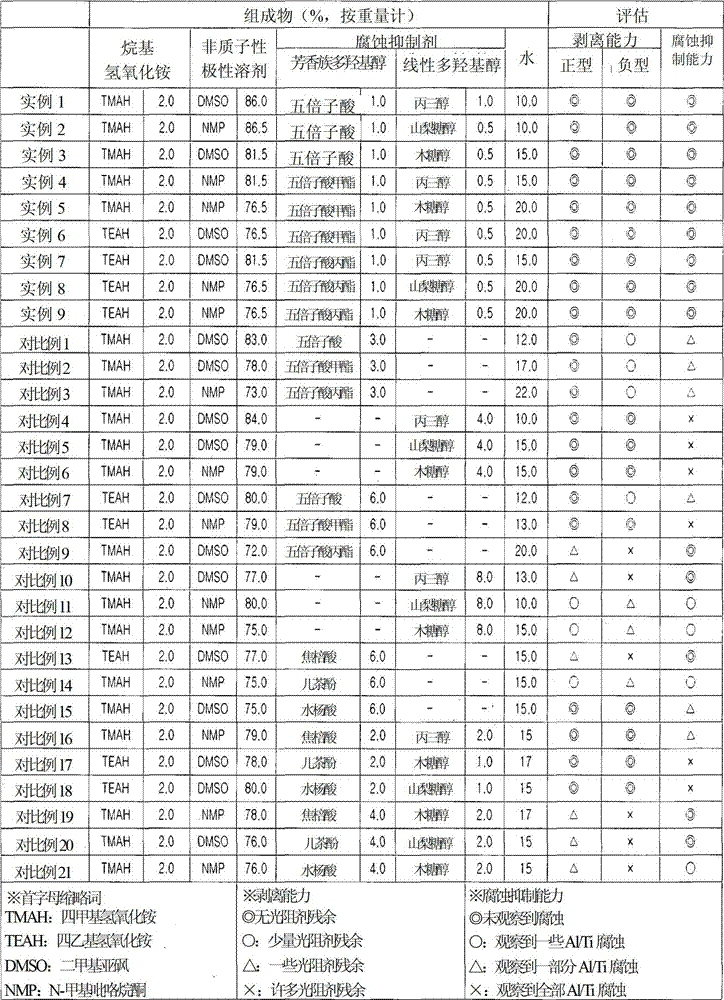

example 1 to 9 and comparative example 1 to 21

[0034] Compositions of Examples 1 to 9 and Comparative Examples 1 to 21 were prepared by mixing the components shown in Table 1.

[0035] Mixing is performed at room temperature for 1 hour or more to fully dissolve the solid corrosion inhibitor, then filtered through a Teflon filter.

experiment example

[0037] The stripping ability and corrosion inhibiting ability of the compositions obtained in Examples 1 to 9 and Comparative Examples 1 to 21 were evaluated as follows:

[0038] (1) Preparation of positive photoresist samples

[0039] Positive photoresist (THMR-iP 3300, TOK) is coated on a silicon wafer coated with silicon nitride, and then a photoresist pattern is formed through exposure and development processes. The pattern was transferred to the silicon nitride layer below the photoresist by dry etching to obtain a positive tone photoresist sample.

[0040] (2) Preparation of negative photoresist samples

[0041] A negative photoresist (PMER N-HC600, TOK) is coated on a silicon wafer, and then a photoresist pattern is formed through exposure, development and baking processes. Aluminum and titanium are sequentially spread on the silicon wafer to obtain a polished negative photoresist pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com