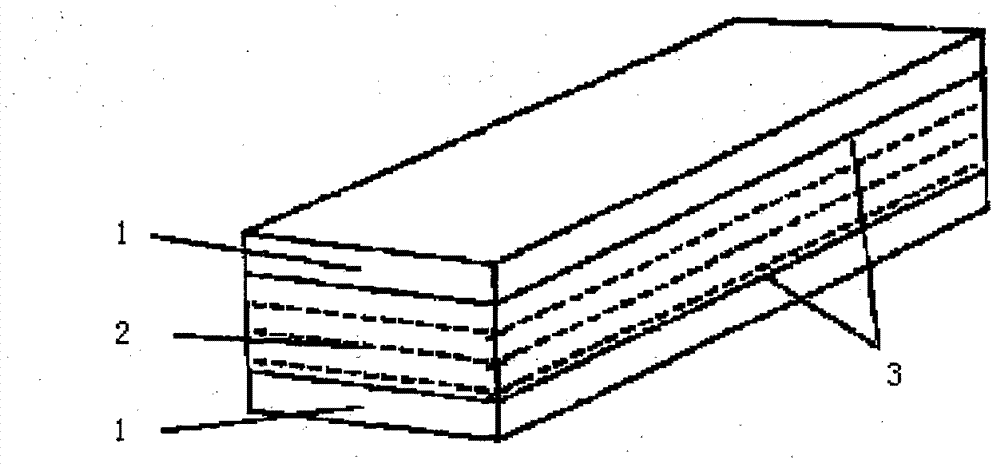

Manufacturing method for composite artificial board (LVS)

A manufacturing method and plate technology, which are applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, can solve the problems that the surface cannot be engraved and milled, are easily warped, and have poor coloring properties, and can protect the large diameter of the forest. high-grade wood resources, promoting healthy development, and reasonable selection of production technology and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

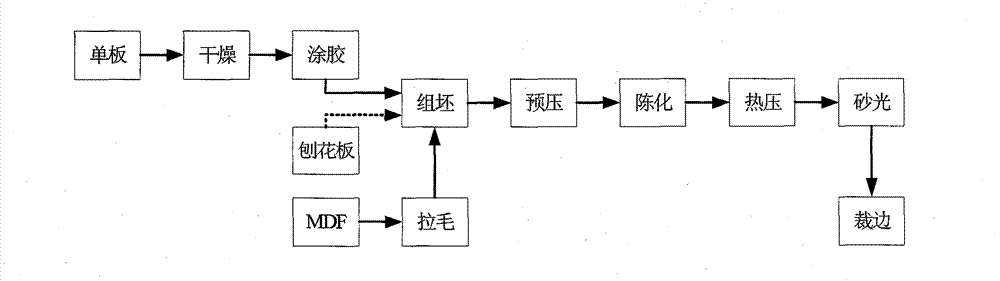

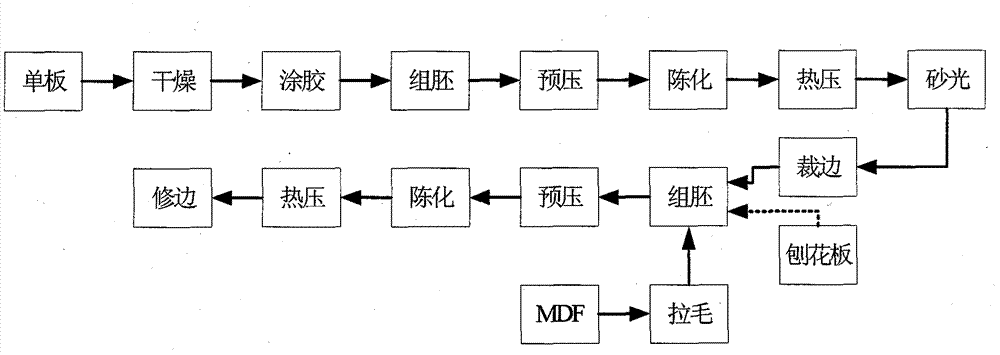

Method used

Image

Examples

Embodiment Construction

[0026] 1. The LVS product made by the secondary molding process of the present invention has high quality, good bonding strength, peeling rate, elastic modulus and other indicators. In addition, the positioning of the upper and lower surfaces of the secondary molding process is relatively easy, so the present invention mainly adopts two LVS is made by secondary molding process method.

[0027] 2. The test results show that the structural parameters and hot-pressing process parameters of test number 4 are relatively ideal, and its static bending strength and internal bonding strength in the vertical direction are higher than those of other test numbers. Its water-absorbing thickness expansion rate is also relatively low, so the present invention mainly adopts the structural parameters and hot-pressing process parameters of No. 4 experimental scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com