High speed railway based aerodynamic aerotrain with simulated wings

An aerodynamic levitation, high-speed railway technology, applied in the field of locomotives and carriages, can solve problems such as waste of resources, inability to change tracks of trains, health, ecological environment balance, and adverse effects of electronic products, and achieve the effect of reducing pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] See Figure 4 and Figure 5 , the structure of the imitation wing is mainly composed of the uppermost horizontal wing 1, the vertical wing 4 of the middle part and the lowermost rotatable base that can rotate 360 degrees; wherein, the rotatable base is a double layer with a diameter of 1 meter. The structure of discs stacked, the thickness of the lower disc 8 of the rotatable base is 25 mm, the thickness of the upper disc 6 of the rotatable base is 65 mm, the upper disc is connected with the lower disc through the rotating shaft 7, and The rotation axis passes through the centers of the two disks; the upper disk can rotate 360 degrees along with the rotation axis. The lower edge of the vertical wing is connected to the central symmetry axis of the upper surface of the upper disk of the rotatable base, and the vertical wing and the rotatable base are at a right angle of 90 degrees; the upper edge of the vertical wing is connected to the It is connected at the cente...

Embodiment 2

[0054] The structure of imitation wing is basically the same as embodiment 1, and the difference is:

[0055] The thickness of the lower disc of the rotatable base is 20 mm, and the thickness of the upper disc of the rotatable base is 60 mm.

[0056] The wing height of the described vertical wing is 70 centimeters, the root-to-shoot ratio is 1, the area is 1.05 square meters (including the vertical wing swing), the leading edge sweep angle is 0 degree, and the trailing edge is vertical.

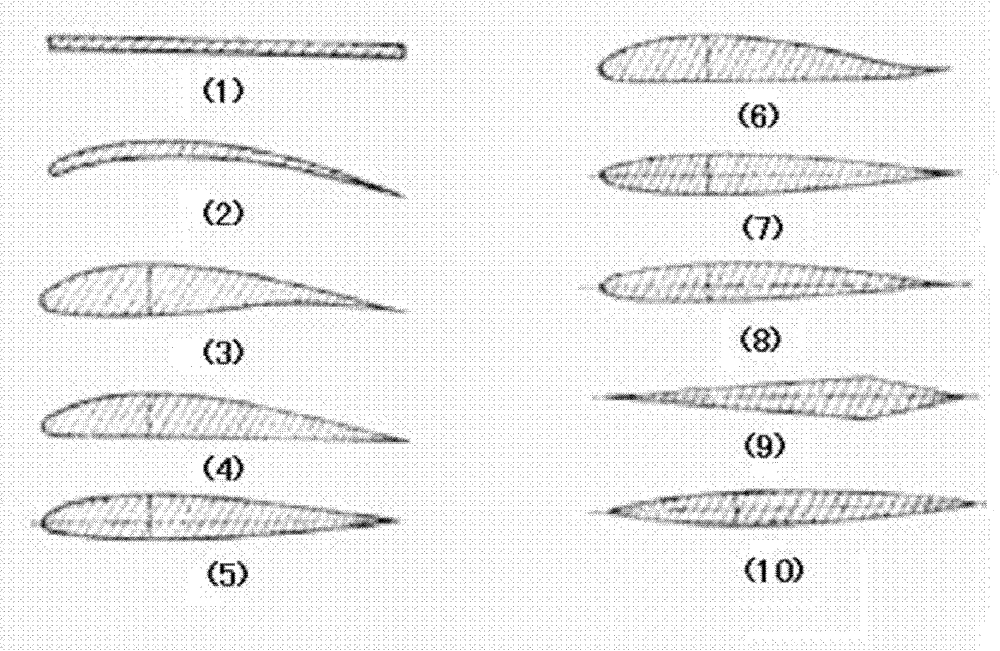

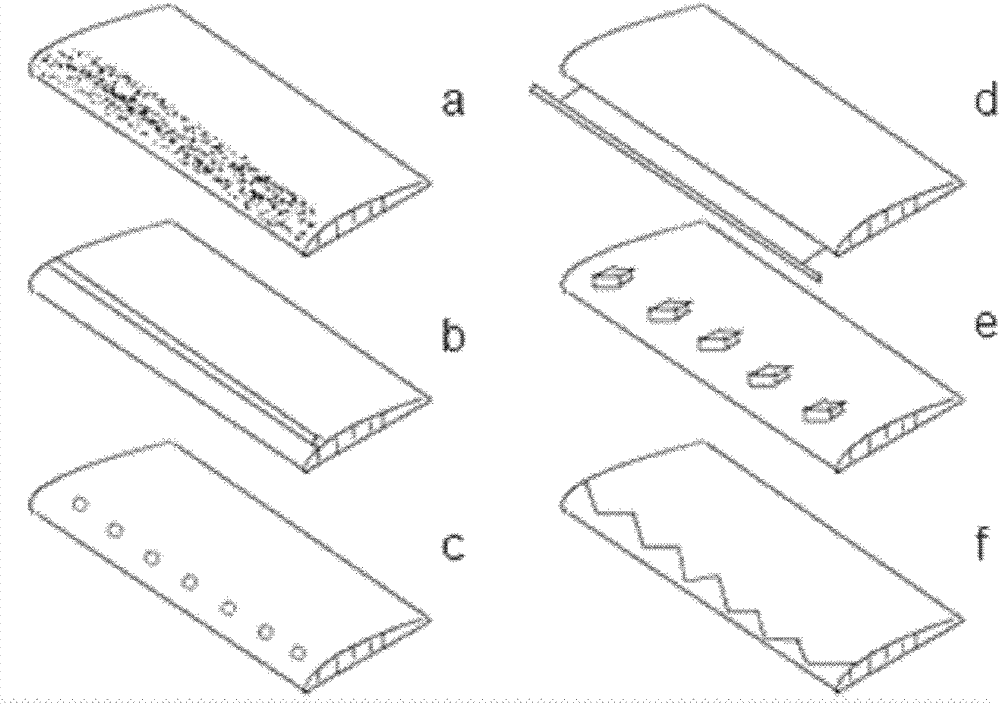

[0057] Described horizontal wing adopts flat wing, and the section of its flat wing is as follows figure 1 Shown in (1), the artificial spoiler structure added near the leading edge part of the upper surface of the horizontal wing is a zigzag protruding spoiler (such as figure 2 shown in f).

[0058] The area of described horizontal wing is 4.5 square meters, and this moment root tip ratio is 1, and the length of horizontal wing is 450 centimetres, and leading edge sweep angle is 0 degr...

Embodiment 3

[0070] The structure of imitation wing is basically the same as embodiment 1, and the difference is:

[0071] The thickness of the lower disc of the rotatable base is 20 mm, and the thickness of the upper disc of the rotatable base is 60 mm.

[0072] The wing height of the described vertical wing is 50 centimeters, the root-to-shoot ratio is 0.5, the area is 0.5 square meters (including the vertical wing swing), the leading edge sweep angle is 26.50 degrees, and the trailing edge is vertical.

[0073] Described horizontal wing adopts flat wing, and the section of its flat wing is as follows figure 1 Shown in (1), the artificial flow disturbance structure added near the leading edge part of the upper surface of the horizontal wing is to add an elastic flow-around band (such as figure 2 shown in d).

[0074] The area of described horizontal wing is 2.25 square meters, and this moment root tip ratio is 0.3, and the length of horizontal wing is 300 centimetres, and leading e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com