Aluminium titanate mullite composite monoblock stopper and preparation method thereof

An integral plug rod, aluminum titanate technology, applied in the field of refractory materials for steelmaking, can solve problems such as large difference in composition, difference in thermal expansion coefficient of materials, and rod head falling off, and achieve strong slag corrosion resistance, long service life, The effect of strong anti-corrosion ability of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

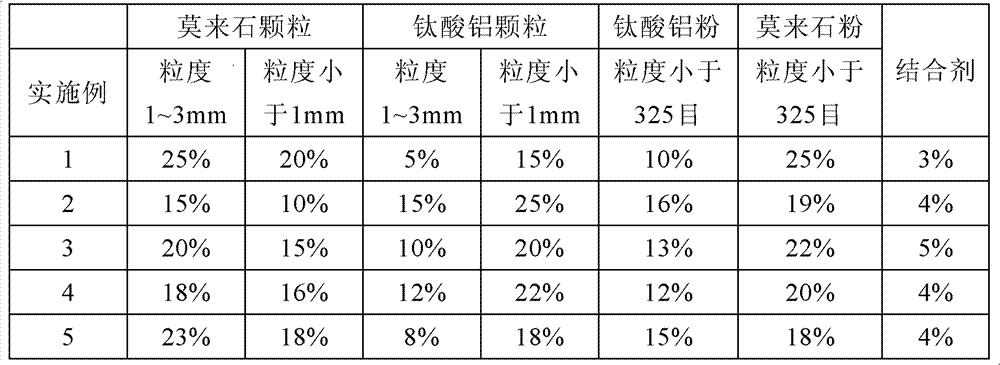

Embodiment 1

[0016] In this embodiment, the raw materials and mass percentages used in the aluminum titanate-mullite composite integral stopper rod are 25% of 1-3mm mullite particles, 5% of 1-3mm aluminum titanate particles, and no more than 1mm mullite particles 20%, 15% aluminum titanate particles not larger than 1mm, 10% aluminum titanate powder not larger than 325 mesh, 25% mullite powder not larger than 325 mesh, plus 3% yellow dextrin.

[0017] The preparation process is as follows: first pre-mix the aluminum titanate powder and mullite powder in the raw materials to make a mixed powder, and then mix and knead according to the order of granules→binder→mixed powder, press and shape after trapping the materials, and form The pressure is 120MPa, and the adobe is fired at 1500°C after drying.

Embodiment 2

[0019] In this embodiment, the raw materials and mass percentages used in the aluminum titanate-mullite composite integral stopper are 15% of 1-3mm mullite particles, 15% of 1-3mm aluminum titanate particles, and no more than 1mm mullite particles 10%, 25% aluminum titanate particles not larger than 1mm, 16% aluminum titanate powder not larger than 325 mesh, 19% mullite powder not larger than 325 mesh, plus 4% lignin.

[0020] The preparation process is as follows: first pre-mix the aluminum titanate powder and mullite powder in the raw materials to make a mixed powder, and then mix and knead according to the order of granules→binder→mixed powder, press and shape after trapping the materials, and form The pressure is 110MPa, and the adobe is fired at 1550°C after drying.

Embodiment 3

[0022] In this embodiment, the raw materials and mass percentages used in the aluminum titanate-mullite composite integral stopper are 20% of 1-3mm mullite particles, 10% of 1-3mm aluminum titanate particles, and no more than 1mm mullite particles 15%, 20% of aluminum titanate particles not larger than 1mm, 13% of aluminum titanate powder not larger than 325 mesh, 22% of mullite powder not larger than 325 mesh, plus 5% of pulp waste liquid.

[0023] The preparation process is as follows: first pre-mix the aluminum titanate powder and mullite powder in the raw materials to make a mixed powder, and then mix and knead according to the order of granules→binder→mixed powder, press and shape after trapping the materials, and form The pressure is 115MPa, and the adobe is fired at 1550°C after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com