Circulation applying process for mother liquor waste water of coupling reaction

A technology of coupling reaction and waste water recycling, applied in azo dyes, monoazo dyes, organic dyes, etc., can solve problems such as environmental hazards, achieve the effect of improving yield, obvious economic benefits, and solving problems of treatment and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

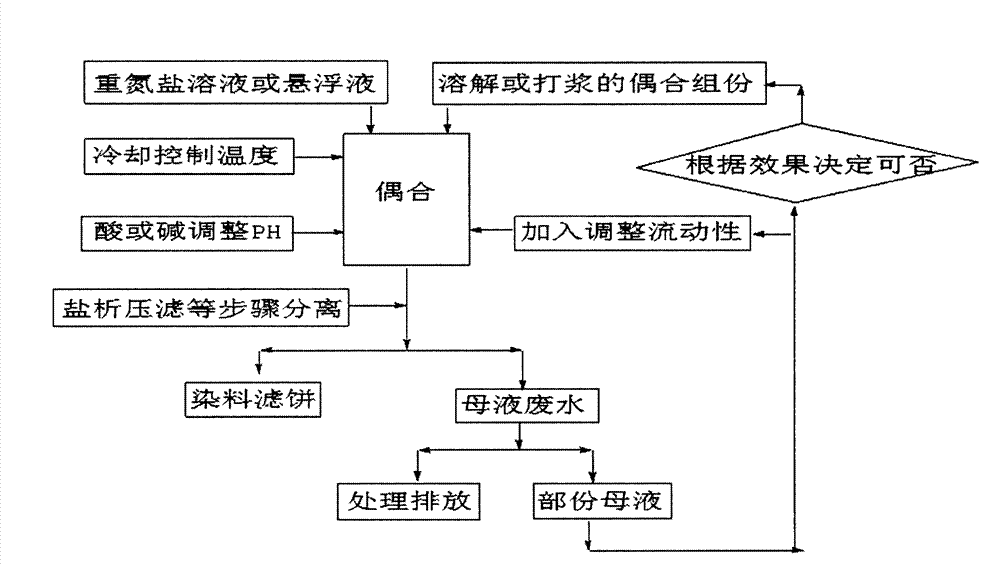

Method used

Image

Examples

example 1

[0014] Example 1: Synthesis of Acid Mordant Brown RH (C.I.Mordant.Brown33):

[0015] (1) Prepare five parts of a 40ml volume containing 0.02172mol p-nitro-o-aminophenol sodium diazonium salt suspension, and set aside;

[0016] (2) 5.6800 g of sodium 2,4 diaminobenzenesulfonate (80.25%), dissolved in 80 ml of water, mixed with a portion of the above-mentioned diazonium salt, adjusted to PH with soda ash, heated and maintained at 50°C, and coupled Salt out after reaching the end point, filter out the acid medium brown RH dye filter cake and dry;

[0017] (3) Replace 80ml of water in step (2) with 80ml of coupling mother liquor, and keep other conditions unchanged, repeat the above coupling reaction, and the experimental results are listed in Table (1).

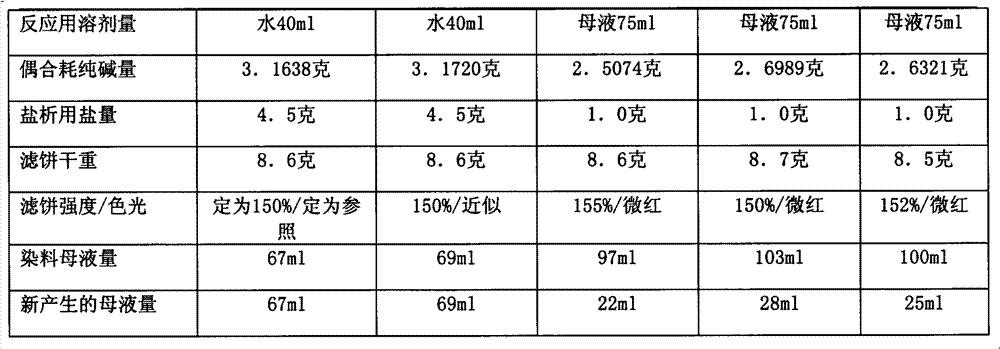

[0018] Table (1) Experimental results of acid medium brown RH

[0019] Experiment sequence

example 2

[0020] Example 2: Synthesis of Disperse Orange F-3R (C.I.Dis.Orange25):

[0021] (1) Prepare four parts of a suspension containing 0.020mol p-nitroaniline diazonium salt with a volume of 15ml, and set aside;

[0022] (2) 3.5340 grams of N-ethyl-N-cyanoethylaniline (98.5%), 30ml of water, 1.85ml of concentrated HCL, after beating for 1.5 hours, cool in an ice bath to a temperature below 10°C, and keep the subsequent reaction at this temperature Within the range, drop a portion of the p-nitroaniline diazonium salt suspension prepared in step (1), adjust the acidity and alkalinity with soda ash, keep the pH around 3.5, filter after the coupling reaction is completed, and obtain the dispersed orange F-3R 14.3 grams of wet filter cake, 30 ml of mother liquor, and the Disperse Orange F-3R wet filter cake was further washed to neutrality and then dried;

[0023] (3) Replace 30ml of water in step (2) with 60ml of coupling mother liquor, and keep other conditions unchanged, repeat the...

example 3

[0026] Example three: the synthesis of acid orange II (C.I.Acid.Orange7):

[0027] (1) Prepare five parts of 32ml suspension containing 0.0200mol diazonium sulfanilate, and set aside;

[0028] (2) Prepare five parts of β-naphthol solution for subsequent use: 2.9087 (99.8%) gram of β-naphthol, 2.6mlNaOH (35%), 7.5ml water, stirring and dissolving into solution;

[0029] (3) Take 40ml of water, add β-naphthol solution and p-aminobenzenesulfonic acid diazonium salt suspension alternately under stirring, keep the temperature below 10°C in an ice bath, add soda ash to keep the pH between 8.5-9.0, After the β-naphthol solution and the diazonium salt suspension of p-aminobenzenesulfonic acid are all dripped, continue the reaction until the coupling end point, salt out and filter out the acid orange II dye filter cake;

[0030] (4) Replace 40ml of water in step (3) with 75ml coupling mother liquor, other conditions are unchanged, repeat above-mentioned coupling reaction, experimental...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com