A method for extracting gallium from fly ash based on resin method

A technology of fly ash and aminopyridine resin, which is applied to the improvement of process efficiency, instruments, optics, etc., can solve the problems of insufficient stability of ascorbic acid reduction solution, increase the difficulty of waste liquid treatment, and large amount of ascorbic acid used, and achieve low cost. control, high recovery rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

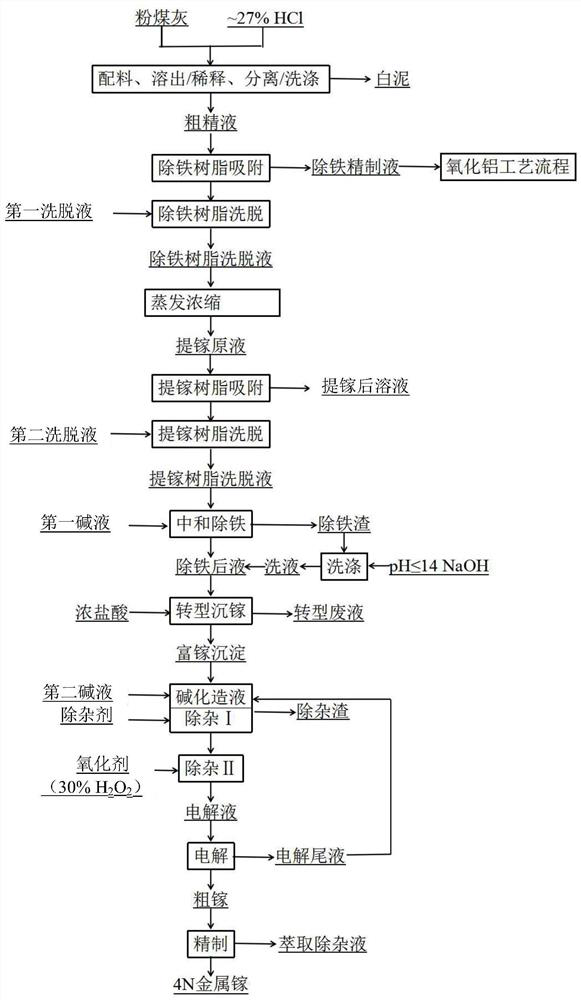

Image

Examples

Embodiment 1

[0052] (1) Separation and preparation of gallium extraction stock solution by resin method

[0053] Pass the crude semen into the strongly basic anion exchange resin (removing iron resin) of model LSC-Fe, the flow rate of the crude semen is 2BV / h, and the adsorption temperature is 70°C. Fe 3+ , Ga 3+ At the same time, it is adsorbed by the resin, and the concentration of ferric chloride and gallium chloride in the refined iron removal solution obtained after adsorption is 0.04g / L, and the concentration of gallium chloride is 0.01g / L, which is used in the subsequent alumina process. After the adsorption is completed, wash the iron-removing resin with 1% hydrochloric acid. The flow rate of the washing liquid is 1BV / h, and the temperature is normal temperature. / L. Evaporating and concentrating the eluent from the iron removal resin, the ferric chloride concentration in the obtained concentrated solution is 405g / L, and the gallium chloride concentration is 2.0g / L, which is the...

Embodiment 2

[0063] (1) Preparation of gallium extraction stock solution by resin method

[0064] According to the method of Example 1, the gallium extraction stock solution is obtained, the difference is that the strong basic anion exchange resin of 201×7 is used as the iron removal resin, and the ferric chloride concentration in the gallium extraction stock solution of the gained is 400g / L, gallium chloride concentration It is 1.60g / L.

[0065] (2) Separation and enrichment of gallium by resin method

[0066] Pass the gallium extraction stock solution into the gallium extraction resin of type 4-APR, the flow rate is 0.8BV / h, and the temperature is normal temperature. The ferric chloride concentration in the gallium-extracting solution obtained after adsorption is 378g / L, and the gallium chloride concentration is 0.007g / L. After the adsorption was completed, the gallium resin was washed with 0.7mol / L sulfuric acid, and the washing liquid flow rate was 1BV / h, and the temperature was norm...

Embodiment 3

[0074] (1) Preparation of gallium extraction stock solution by resin method

[0075] According to the method of Example 1, the gallium extraction stock solution is obtained, the difference is that the strong basic anion exchange resin of 201×4 is used as the iron removal resin, and the ferric chloride concentration in the obtained gallium extraction stock solution is 380g / L, and the concentration of gallium chloride is 380g / L. It is 1.3g / L.

[0076] (2) Separation and enrichment of gallium by resin method

[0077] Pass the gallium extraction stock solution into the gallium extraction resin of type 4-APR, the flow rate is 0.6BV / h, and the temperature is normal temperature. The ferric chloride concentration in the gallium-extracting solution obtained after adsorption is 360 g / L, and the gallium chloride concentration is 0.005 g / L. After the adsorption was completed, the gallium resin was washed with 0.5mol / L nitric acid, and the washing liquid flow rate was 1BV / h, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com