Fruit cooking machine

A fruit machine and cooking technology, applied in application, food processing, food preparation and other directions, can solve the problems of high operating cost, less processing volume, complex structure, etc., and achieve the effect of saving energy, regulating output and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

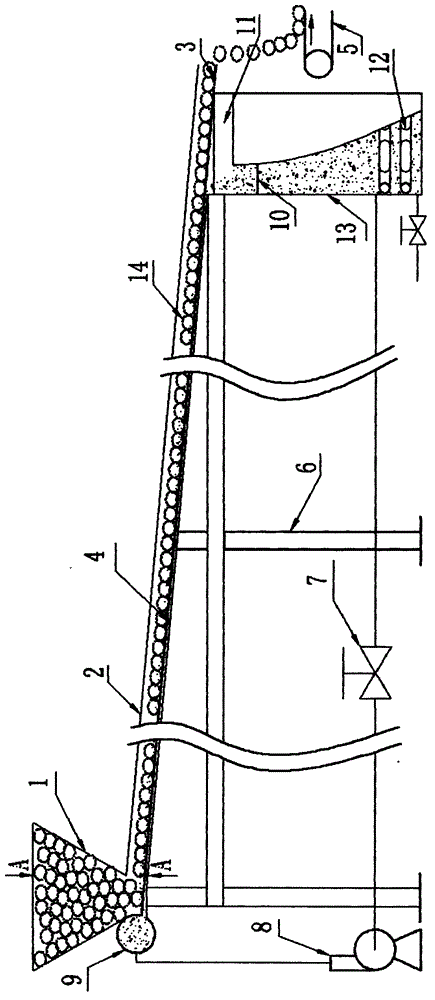

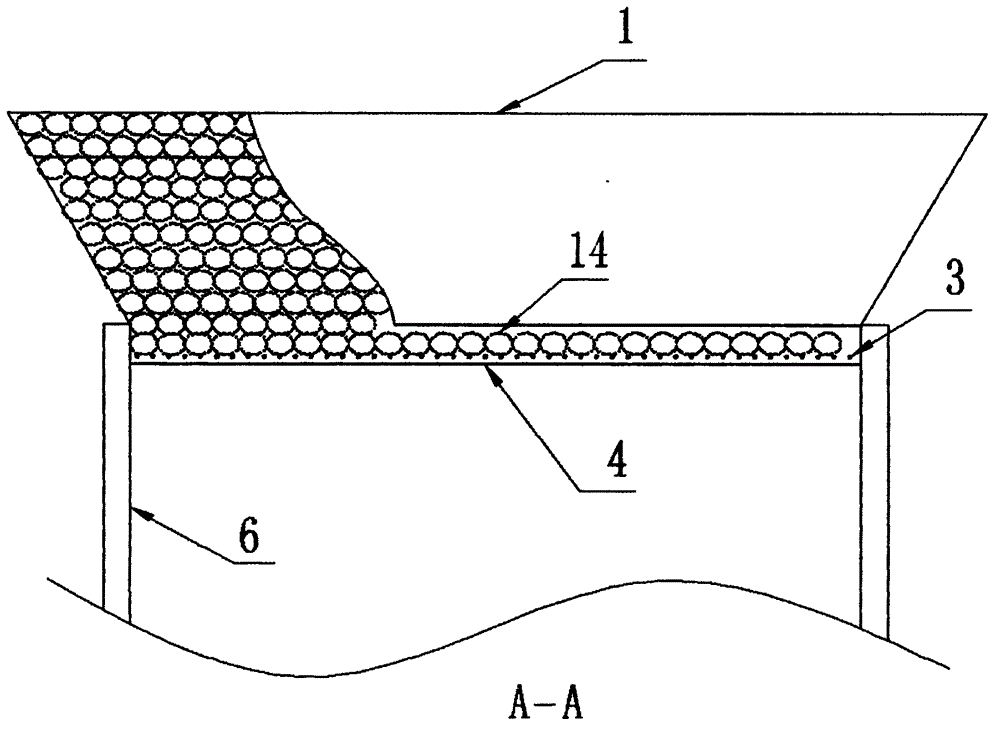

[0019] The specific embodiment of the present invention is used for cooking oval jujube. Generally, the size of jujube is 19-48 mm and the size is 12-36 mm. The cleaned oval jujube is heated in hot water at 100°C ± 5°C. , from high to low, the slope is on the grid 3 of the bracket 4 at 5 degrees. After 1-5 minutes of cooking, the peel can be cracked, and then it will fall into the conveyor belt 5 and enter the next process flow or other connection to the next process flow. device of.

[0020] During manufacture, the fruit bucket 1 is made of 304 stainless steel plate with a thickness of 1-1.5mm to make the upper part 1.6*0.5m, and the lower part 1.2*0.05m high 0.5m. The length 9.6m of bracket 4 is 1.2m in width and 7cm in height is made of 304 stainless steel plate thickness 1-1.5mm. The mesh grid 3 is made of 304 stainless steel wire with a diameter of 3mm and 7 pieces are assembled in the bracket 4 with an interval of 1cm, a length of 1.5m, a width of 1.18m and a height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com