Gas-liquid membrane contactor and mixed gas separation method using same

A gas-liquid membrane contactor and liquid technology, applied in the field of membrane separation, can solve the problems of difficult assembly, unstable mass transfer efficiency and high cost, achieve convenient assembly and cleaning, avoid uneven distribution density of hollow fibers, and compact device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

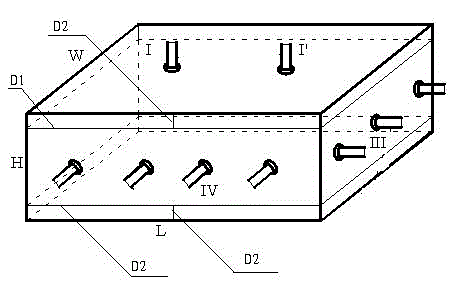

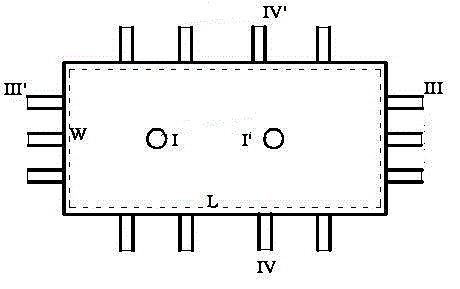

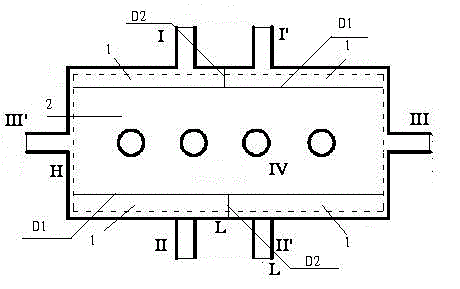

[0041] Example 1 Description of the structure of the gas-liquid film contactor

[0042] like Figure 1 to Figure 8 As shown, a multi-channel gas-liquid film contactor, including a rectangular frame such as figure 1 In the rectangular parallelepiped structure, the air cavity plate fixed between the upper and lower surfaces of the frame is shown as a D1 laminate in the figure, and the air cavity plate - D1 divides the inner cavity of the frame into an air cavity 1 and a liquid cavity 2; The top surface of the air chamber 1 is provided with gas interfaces I and I' in pairs on the same side, and the opposite outer surface of the liquid chamber 2 is provided with liquid interfaces III and III' in pairs, and another air chamber plate D2 is also included. Chamber 1 is divided into two separate sub-air chambers, and the paired gas ports communicate with different sub-air chambers respectively, that is to say, gas port I communicates with the left sub-air chamber, and gas port I' comm...

Embodiment 2

[0047] According to different separation situations, select different cuboid sizes and match them with hollow fiber membranes of suitable materials, set the interval and effective length, that is, the horizontal length, according to the preferred separation method, and conduct tests.

example 2-1

[0049] refer to figure 1 As shown in -8, a multi-channel gas-liquid membrane contactor for separating mixed gases, its structure: L = 100 cm, W = 15 cm, H = 10 cm, air cavity D = 1.25 cm, hollow fiber PP membrane wire arrangement The interval is 0.5cm, and the effective length of the shortest membrane filament is 50%L.

[0050] Operation process: gas mixture composition N 2 / CO 2 , pressure 0.1MPa, CO 2 Mole fraction 25%, flow rate 1.5L / min; liquid (absorbent) 30% MEA, flow rate 300mL / min. 1) The gas-liquid process is operated in parallel (I→I', II→II'); the liquid process III→III' forms a countercurrent flow with the gas. At this time, compared with the existing hollow fiber membrane contactor of the same scale, the fraction Efficiency increased by 28%. 2) The gas-liquid process is operated in parallel (I→I', II→II'); the liquid process III'→III forms a co-current flow with the gas. At this time, compared with the existing hollow fiber membrane contactor of the same scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com