Hydraulic simulation device capable of controlling ingot segregation and method

A technology of hydraulic simulation and ingot casting mold, which is applied in the fields of ingot casting, metallurgy and casting, which can solve the problems of water flow disturbance, difficult installation, low sensitivity and response speed, etc., and achieve the effects of small flow disturbance, real-time acquisition and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

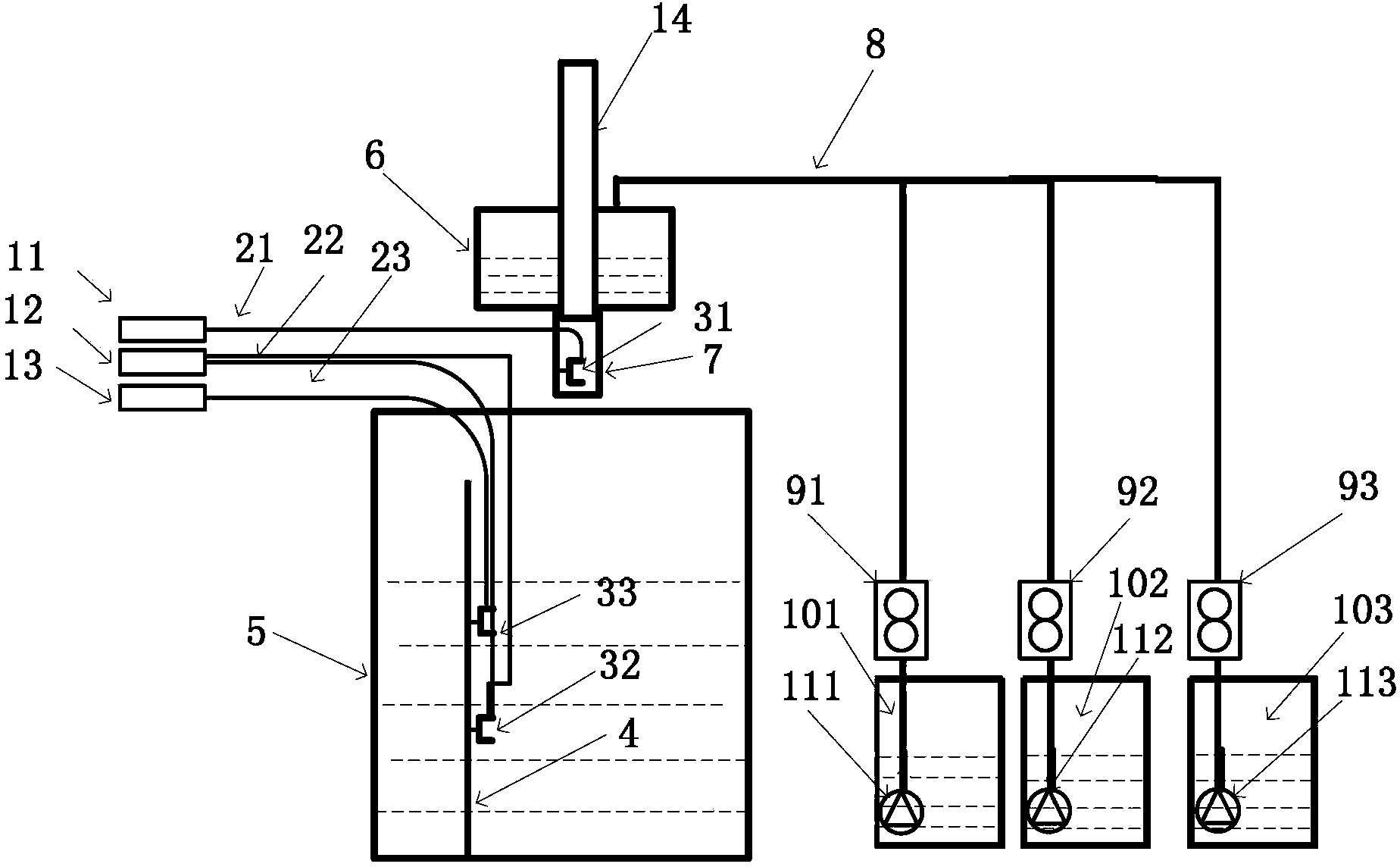

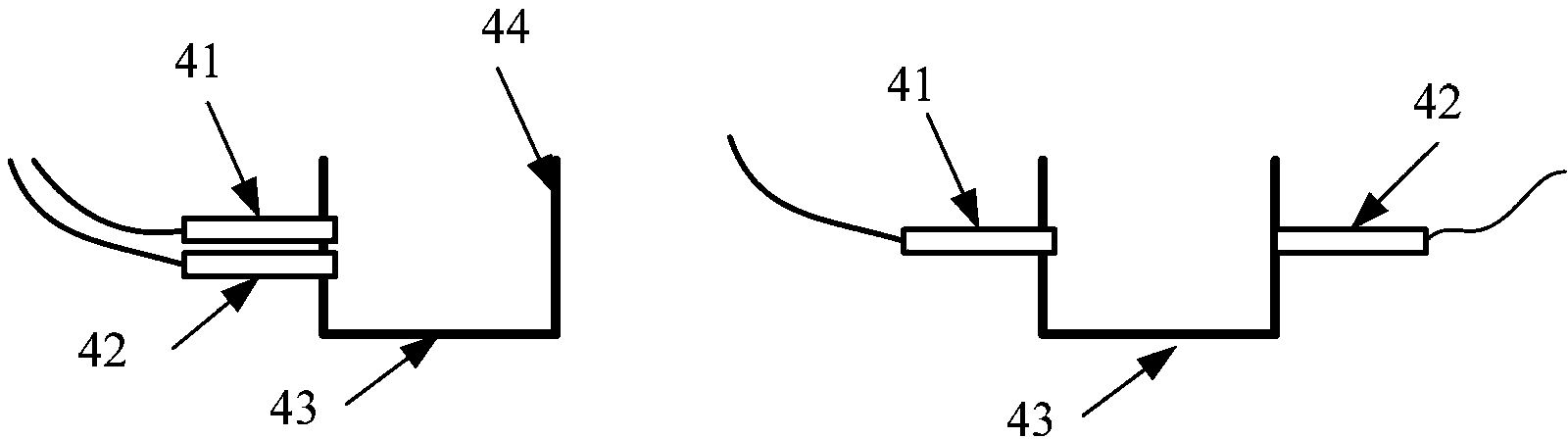

[0036] (1) According to figure 1 The schematic diagram of the device shown is connected to various devices: fix the first U-shaped fiber optic probe 31 on the inner wall of the water outlet 7 of the casting tundish, fix the second U-shaped fiber optic probe 32 and the third U-shaped fiber optic probe 33 on the On the probe bracket 4; in this embodiment, the optical fiber line selects a standard M6 reflective optical fiber pair, and the distance between the optical fiber signal transmitter 41 and the reflective surface 44 is 10 mm;

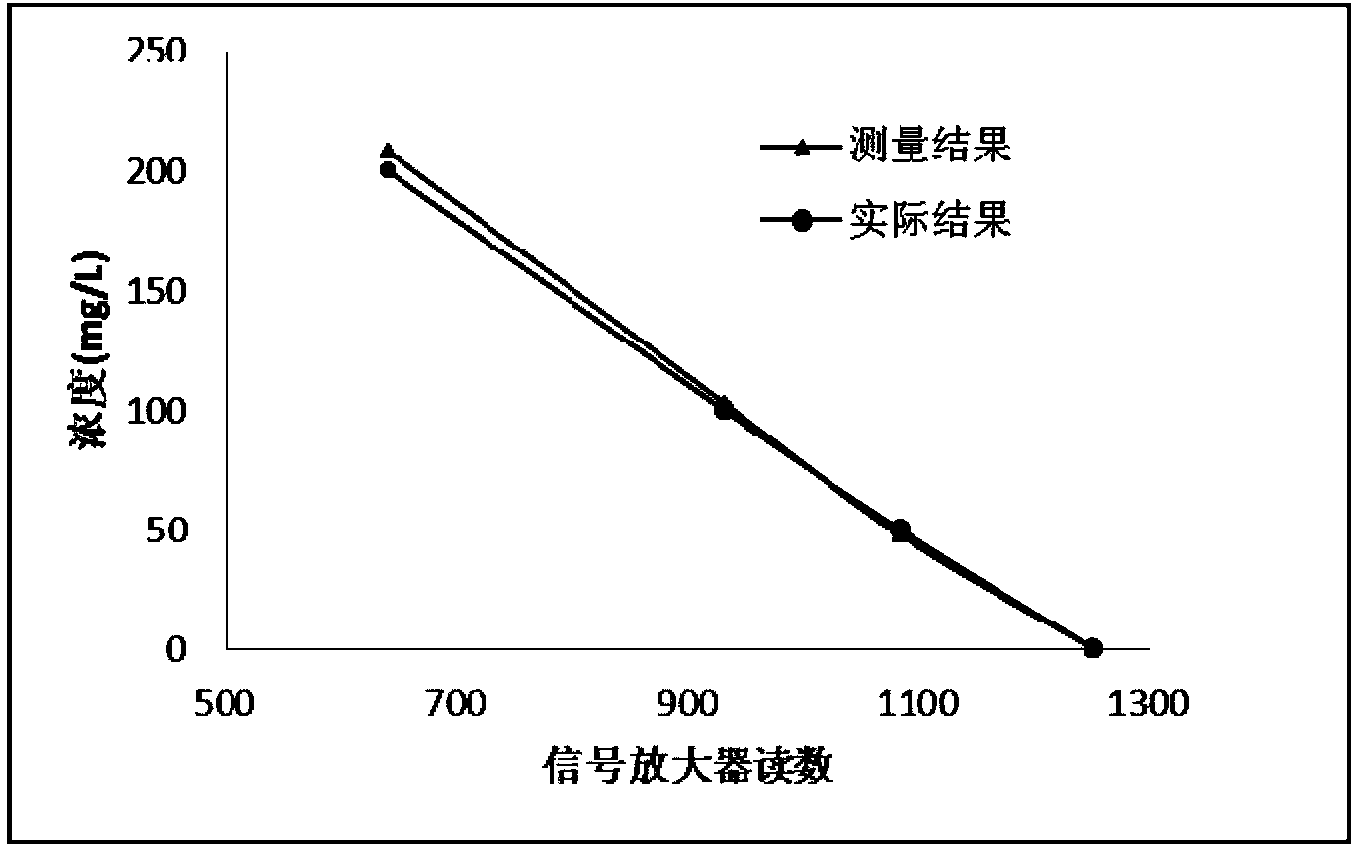

[0037](2) Choose methylene blue and prepare 7 kinds of colored aqueous solutions with different concentrations: 0 mg / L (distilled water), 20mg / L, 40mg / L, 50mg / L, 100mg / L, 200mg / L, 400mg / L ;Starting from the methylene blue solution of 0 mg / L (distilled water), according to the order of increasing concentration, test the light transmittance of the methylene blue aqueous solution of each concentration in the following way: inject the methylene blue aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com