Method for manufacturing polarization-preserving optical fiber

A polarization-maintaining fiber and polarization-maintaining core rod technology, which is applied to polarization fibers, cladding fibers, glass manufacturing equipment, etc. The effect of production, ensuring longitudinal uniformity and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a polarization-maintaining optical fiber, comprising the steps of:

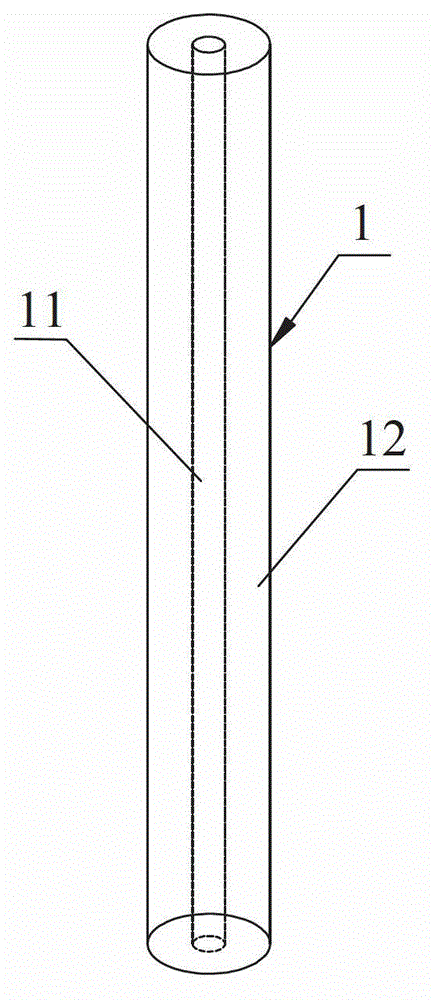

[0035] S1. If figure 1 and Figure 6 As shown, the polarization-maintaining mandrel 1 and two boron-doped stress rods 2 are prepared by PCVD process, the polarization-maintaining mandrel 1 has a core 11 and a cladding 12; the doping composition of the boron-doped stress rod 2 is B 2 o 3 , the relative refractive index difference between the boron-doped stress rod 2 and the quartz glass is between -0.40%~-0.80%, and the boron-doped stress rod 2 has a stress region 21 .

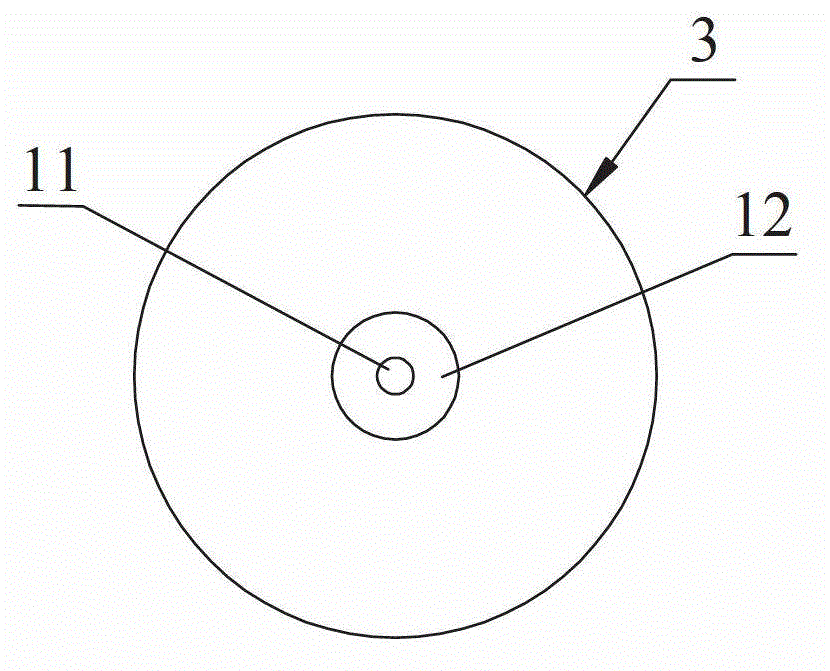

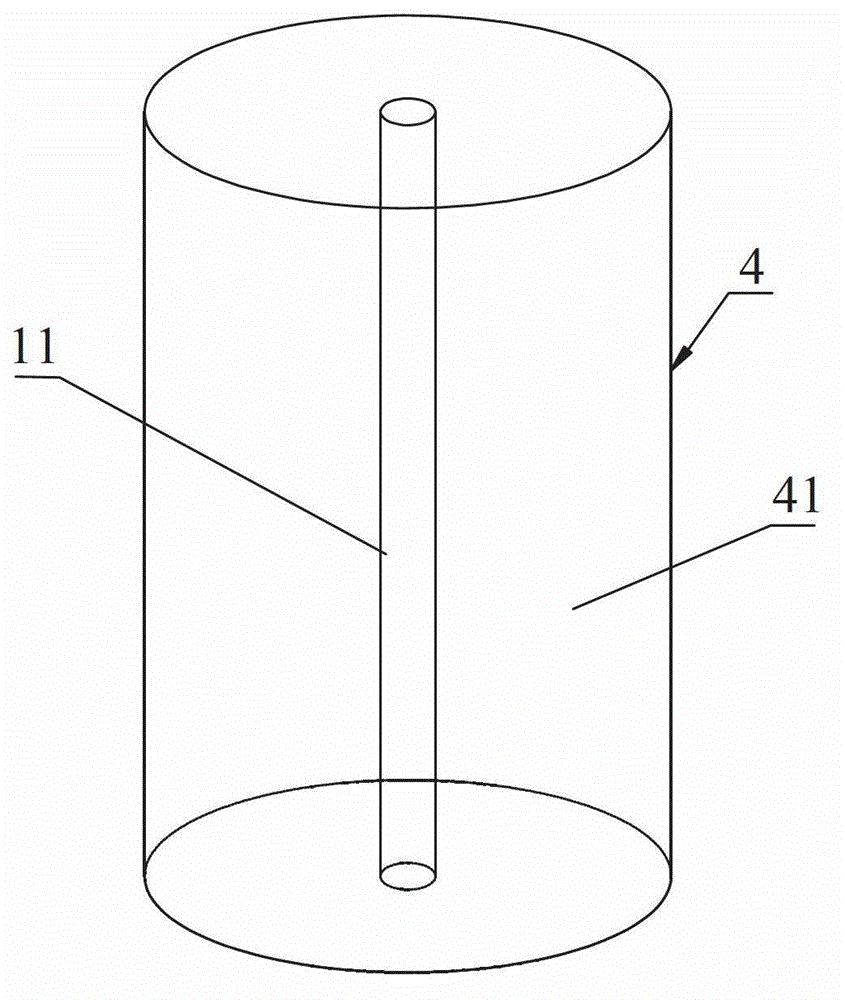

[0036] S2. If figure 2 and image 3 As shown, the polarization-maintaining mandrel 1 is melted into a solid rod with a quartz sleeve 3 at a high temperature of 2000°C to 2200°C, and then thinned to obtain a polarization-maintaining master rod 4, wherein the polarization-maintaining mandrel 1 is wrapped The layer 12 and the quartz sleeve 3 are melted at high temperature to form the quartz cladding 41 of the p...

Embodiment 1

[0042] Such as Figure 1 to Figure 7 As shown, in this embodiment, the polarization-maintaining mandrel 1 and two boron-doped stress rods 2 are first prepared by PCVD process. The diameter of the polarization-maintaining mandrel 1 is 21mm, and the diameter of the core is 3.9mm. Then, the polarization-maintaining mandrel is melted and thinned with a quartz sleeve with a cross-sectional area of 3100mm2 to obtain the polarization-maintaining master rod 4. The size of the polarization-maintaining master rod 4 is 30-35 mm, and the doping depth of the boron-doped stress rod 2 is -0.40%. The diameter of the boron-doped stress rod is 8.5-10.5mm; the diameter of each round hole 42 processed on the polarization-maintaining mother rod 4 is 9-11mm, and each boron-doped stress rod 2 is close to the inner edge of the core 11 and the center of the core 11 The distance R between them, the ratio of r to the core radius is 2.0, that is, R / r=2.0, and the depth of the round hole is 400mm; final...

Embodiment 2

[0046] Such as Figure 1 to Figure 7 As shown, in this embodiment, the polarization-maintaining mandrel 1 and two boron-doped stress rods 2 are first prepared by PCVD process. The diameter of the polarization-maintaining mandrel 1 is 21mm, and the diameter of the core is 4.2mm. Then use the polarization maintaining mandrel with a cross-sectional area of 3100mm 2 The quartz sleeve is melted and thinned to obtain the polarization maintaining master rod 4, the size of the polarization maintaining master rod 4 is 35~40mm, the doping depth of the boron-doped stress rod 2 is -0.80%, and the diameter of the boron-doped stress rod is 10.5~12.5mm; The diameter of each circular hole 42 processed on the polarization-maintaining master rod 4 is 11-13 mm, and the distance R between the inner edge of each boron-doped stress rod 2 close to the core 11 and the center of the core 11 is equal to the radius of the core. The ratio of r is 2.2, that is, R / r=2.2, and the depth of the round hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com