Treatment method for improving adhesion of asphalt with aggregates

A treatment method and adhesion technology, which is applied in the field of asphalt pavement materials, can solve the problems of high mutual repulsion between anti-stripping substances and asphalt or stone materials, difficulty in operation, pollution of the environment, etc., to improve water damage resistance and stability Good, easy to deal with the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

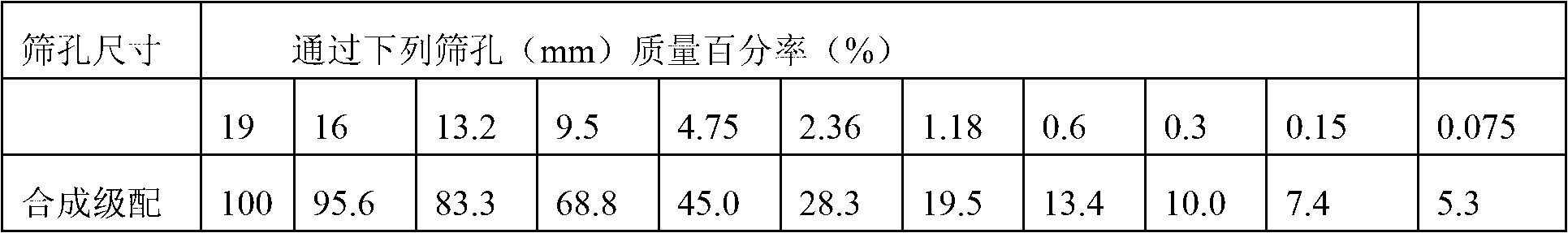

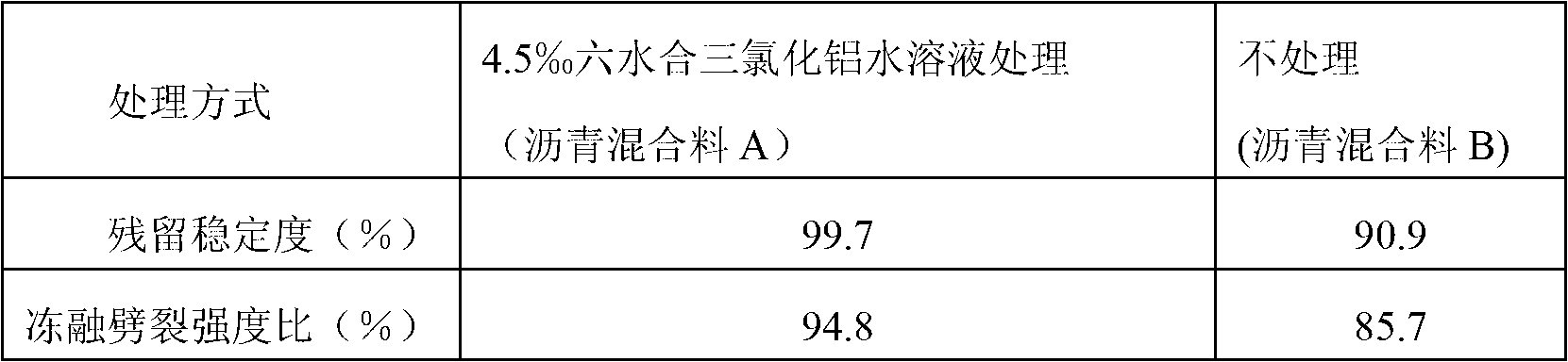

Embodiment 1

[0018] The asphalt used in a certain project is 70# matrix asphalt, and the stone material is granite.

[0019] ⑴. Mix 4.5 kg of aluminum trichloride hexahydrate with 995.5 kg of drinking water at room temperature, and stir evenly to obtain an aqueous solution of aluminum trichloride hexahydrate with a concentration of 4.5‰.

[0020] (2) Infiltrate the granite aggregate with the above-mentioned aluminum chloride hexahydrate aqueous solution, and take it out immediately after the surface of the granite aggregate is fully infiltrated. The infiltration process is 10s;

[0021] ⑶. After the granite aggregate is dried or dried, the asphalt mixture can be mixed according to the conventional method.

[0022] Test 1. Adhesion level test between asphalt and granite in asphalt mixture

[0023] After drying the infiltrated basalt aggregates in this example, a water boiling test was carried out. At the same time, the water boiling test of granite that has not been treated by this method...

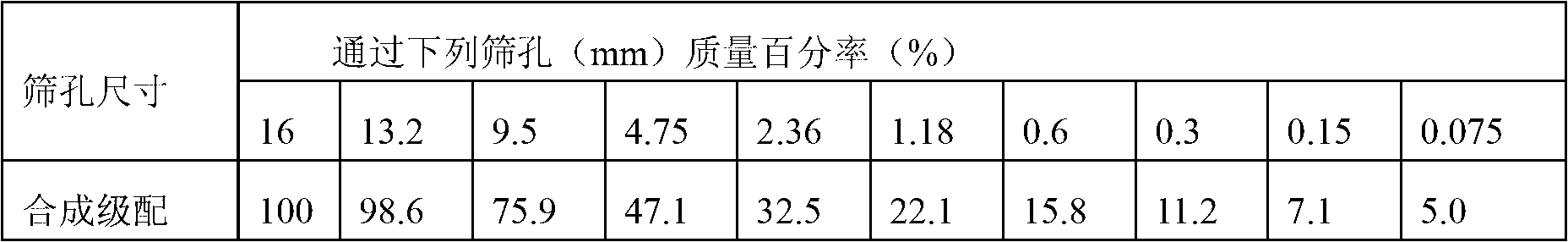

Embodiment 2

[0036] The asphalt used in a certain project is SBS matrix asphalt, and the stone material is basalt.

[0037] ⑴. Mix 5 kg of aluminum trichloride hydrate with 995 kg of drinking water at room temperature, and stir evenly to obtain an aqueous solution of aluminum trichloride hexahydrate with a concentration of 5‰.

[0038] (2) Infiltrate the basalt aggregate with the above-mentioned aluminum chloride hexahydrate aqueous solution, and take it out immediately after the surface of the basalt aggregate is completely infiltrated. The infiltration process is 13s;

[0039] ⑶. After the basalt aggregate is dried or dried, the asphalt mixture can be mixed according to the conventional method.

[0040] Test 1. Adhesion grade test between asphalt and basalt in asphalt mixture:

[0041] After drying the infiltrated basalt aggregates in this example, a water boiling test was carried out. At the same time, the water boiling test of basalt that has not been treated by this method is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com