Preparation method of antislip ceramic aggregate

An anti-skid and aggregate technology, which is applied in the field of preparation of ceramic anti-skid materials to achieve the effect of chemical and physical stability, various colors, and thin coating for marking construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

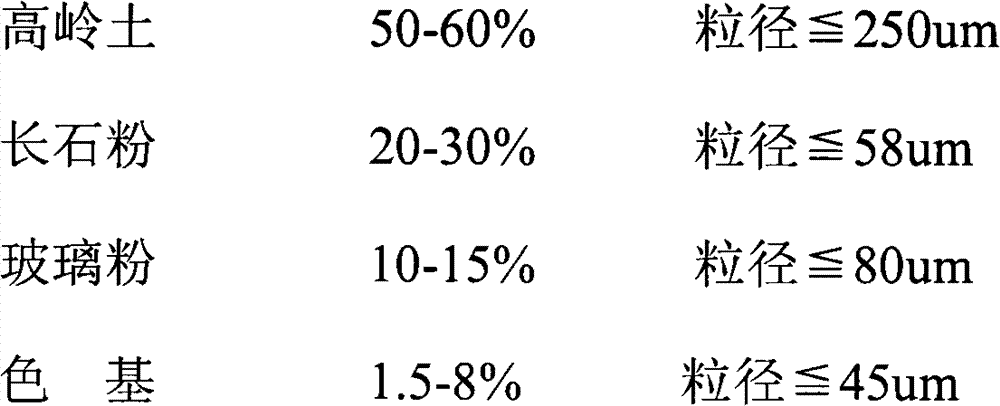

[0013] (1) get the weight percent of formula to form the raw material of following ratio:

[0014] Kaolin 55.9%, particle size ≤150um;

[0015] Feldspar powder 27.6%, particle size ≤58um;

[0016] Glass powder 15.0%, particle size ≤ 80um;

[0017] High temperature inorganic color base 1.5%, particle size ≤ 45um;

[0018] (2) Take the above-mentioned raw materials into the ball mill according to the weight percentage, take water as the medium, and the amount of water added is 30% of the total weight of the raw materials, and the mixing ball milling time is 10 hours. hour, dehydrate the mud with a mud press or a high-speed centrifuge to obtain mud blocks, put the mud blocks into the drying room for drying, and after the mud billets are completely dry, take out the mud billets and use a ceramic double roller machine to roll and dry the mud billets. The block is ground and granulated, and the gap between the rollers can be adjusted according to the particle size of the product....

Embodiment 2

[0023] (1) get the weight percent of formula to form the raw material of following ratio:

[0024] Kaolin 60%, particle size ≤ 250um;

[0025] Albite powder 20%, particle size ≤58um;

[0026] Glass powder 15%, particle size ≤ 80um;

[0027] High temperature inorganic color base 5%, particle size ≤ 45um;

[0028] (2) Take the above-mentioned raw materials into the ball mill according to the weight percentage, take water as the medium, and the amount of water added is 40% of the total weight of the raw materials. The mixing ball milling time is 8 hours. After the ball milling is completed, the mud is poured into the pool and stale for 16 hour, dehydrate the mud with a mud press or a high-speed centrifuge to obtain mud blocks, put the mud blocks into the drying room for drying, and after the mud billets are completely dry, take out the mud billets and use a ceramic double roller machine to roll and dry the mud billets. The block is ground and granulated, and the gap between th...

Embodiment 3

[0033] (1) get the weight percent of formula to form the raw material of following ratio:

[0034] Kaolin 50%, particle size ≤150um;

[0035] Albite powder 30%, particle size ≤58um;

[0036] Glass powder 12%, particle size ≤ 80um;

[0037] High temperature inorganic color base 8%, particle size ≤ 45um;

[0038] (2) Take the above-mentioned raw materials into the ball mill according to the weight percentage, take water as the medium, and the amount of water added is 40% of the total weight of the raw materials. The mixing ball milling time is 8 hours. After the ball milling is completed, the mud is poured into the pool and stale for 16 hour, dehydrate the mud with a mud press or a high-speed centrifuge to obtain mud blocks, put the mud blocks into the drying room for drying, and after the mud billets are completely dry, take out the mud billets and use a ceramic double roller machine to roll and dry the mud billets. The block is ground and granulated, and the gap between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com