Method for preparing elastic and glossy dacron drawing yarns with potential crimps

A curling elastic, light polyester technology, applied in the direction of stretch spinning, melt spinning, filament/thread forming, etc., to achieve the effect of small air volume, low equipment investment and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

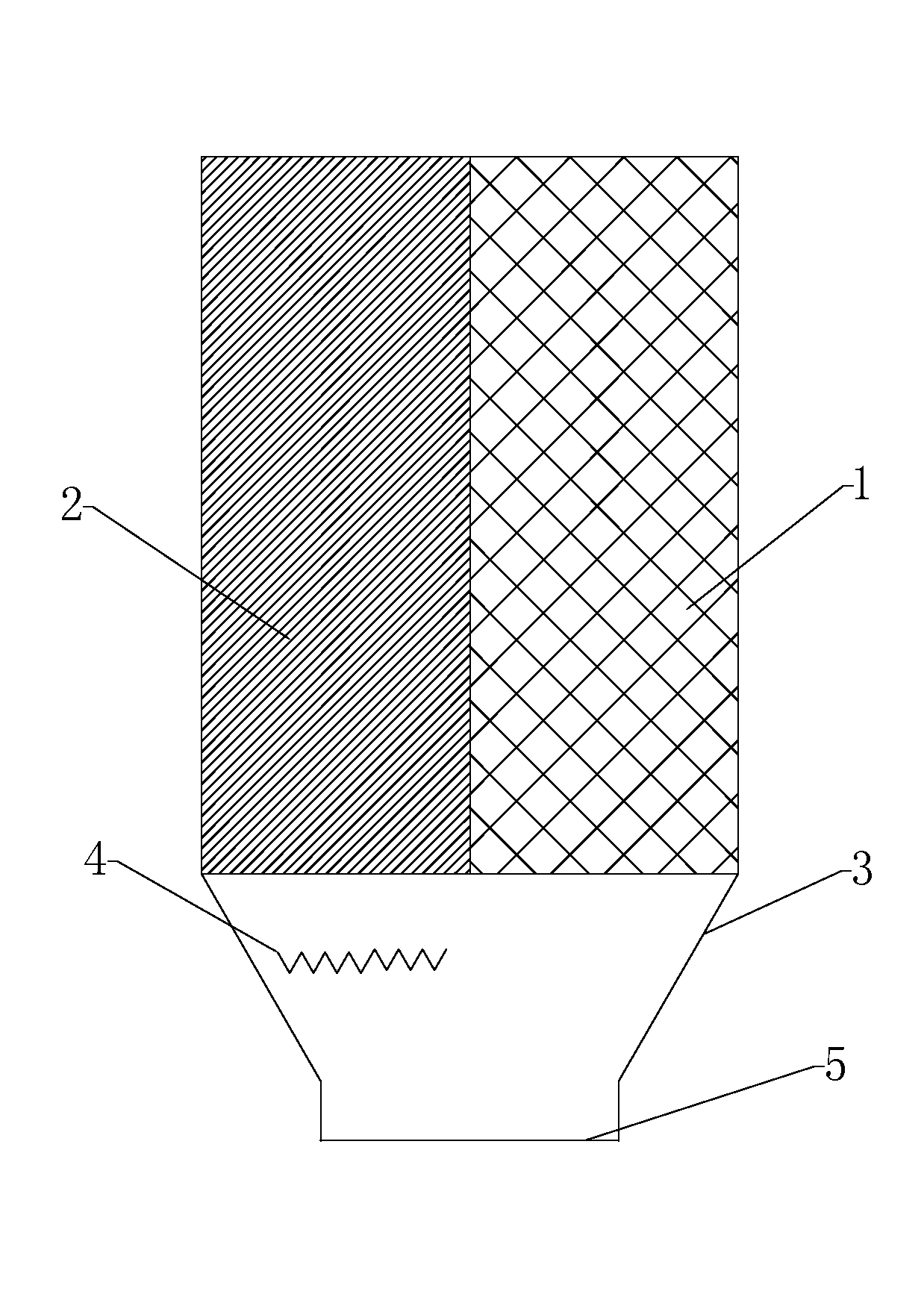

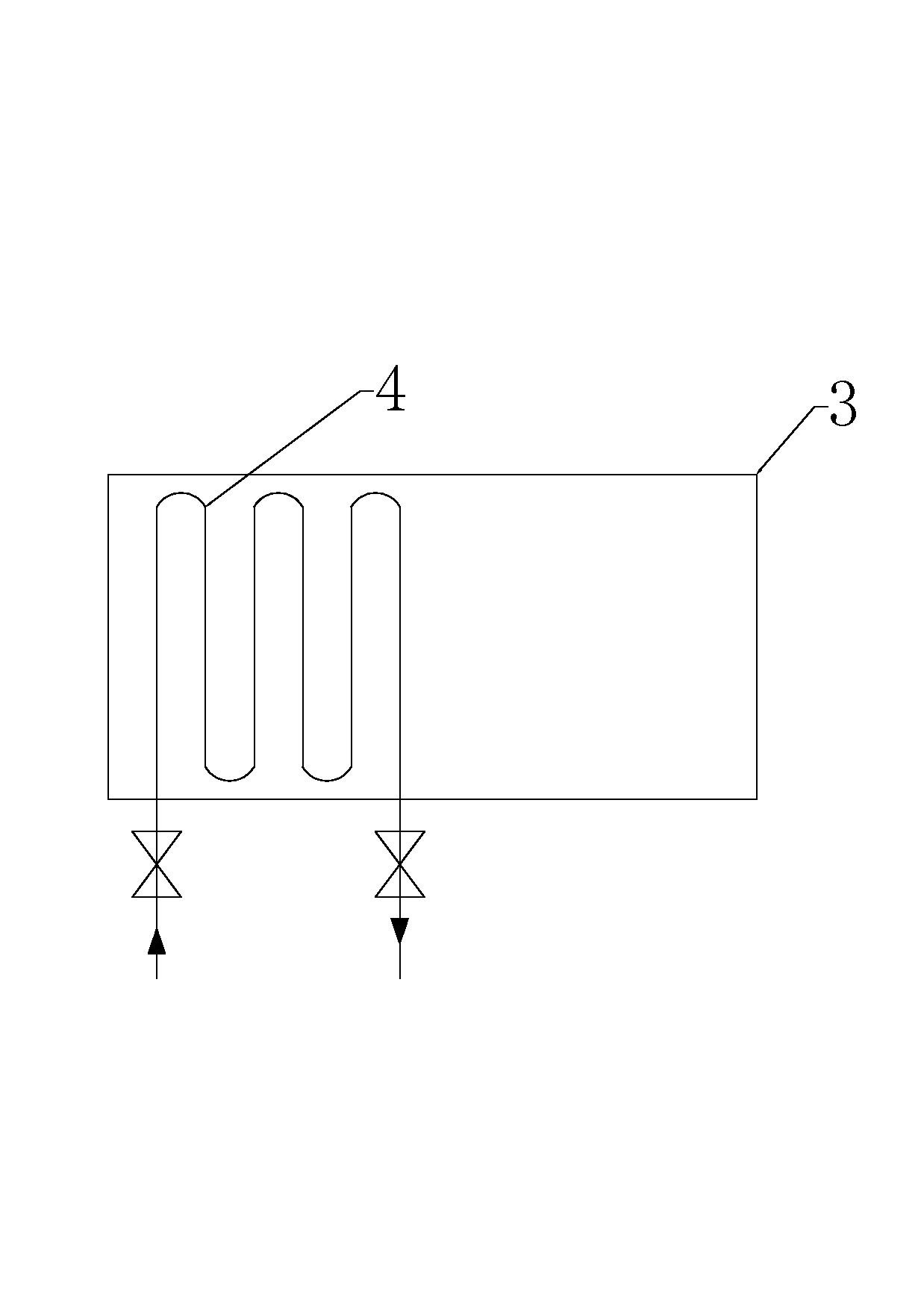

[0019] A kind of preparation method of latent crimp elastic glossy polyester drawing yarn, take the glossy direct-spinning melt that is made by the polymerization of purified terephthalic acid and ethylene glycol as raw material, comprising the following steps: (1) direct-spinning bright Under the action of the booster pump, the spinning melt passes through the melt conveying pipeline with a temperature of 280°C. The melt conveying pipeline adopts biphenyl gas phase heat medium to adjust the melt temperature. In order to prevent serious spinning and spinning , Broken end phenomenon, can control the residence time of the melt, and prevent the degradation of polyester macromolecules from being aggravated after a long stay. At the same time, it is transported into the spinning box under the action of the booster pump, and the pressure provided by the booster pump is 8kg / cm 2 , and after being accurately metered by the metering pump, the speed of the metering pump is 37 rpm, the c...

Embodiment 2

[0021] A kind of preparation method of latent crimp elastic glossy polyester drawing yarn, take the glossy direct-spinning melt that is made by the polymerization of purified terephthalic acid and ethylene glycol as raw material, comprising the following steps: (1) direct-spinning bright Under the action of the booster pump, the spinning melt passes through the melt conveying pipeline with a temperature of 280°C. The melt conveying pipeline adopts biphenyl gas phase heat medium to adjust the melt temperature. In order to prevent serious spinning and spinning , Broken end phenomenon, can control the residence time of the melt, and prevent the degradation of polyester macromolecules from being aggravated after a long stay. At the same time, it is transported into the spinning box under the action of the booster pump, and the pressure provided by the booster pump is 9kg / cm 2 , and after being precisely metered by the metering pump, the speed of the metering pump is 38 rpm, the co...

Embodiment 3

[0023] A kind of preparation method of latent crimp elastic glossy polyester drawing yarn, take the glossy direct-spinning melt that is made by the polymerization of purified terephthalic acid and ethylene glycol as raw material, comprising the following steps: (1) direct-spinning bright Under the action of the booster pump, the spinning melt passes through the melt conveying pipeline with a temperature of 280°C. The melt conveying pipeline adopts biphenyl gas phase heat medium to adjust the melt temperature. In order to prevent serious spinning and spinning , Broken end phenomenon, can control the residence time of the melt, and prevent the degradation of polyester macromolecules from being aggravated after a long stay. At the same time, it is transported into the spinning box under the action of the booster pump, and the pressure provided by the booster pump is 10kg / cm 2 , and after being accurately metered by the metering pump, the speed of the metering pump is 39 rpm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com