Preparation method of aqueous sizing agent for carbon fibers

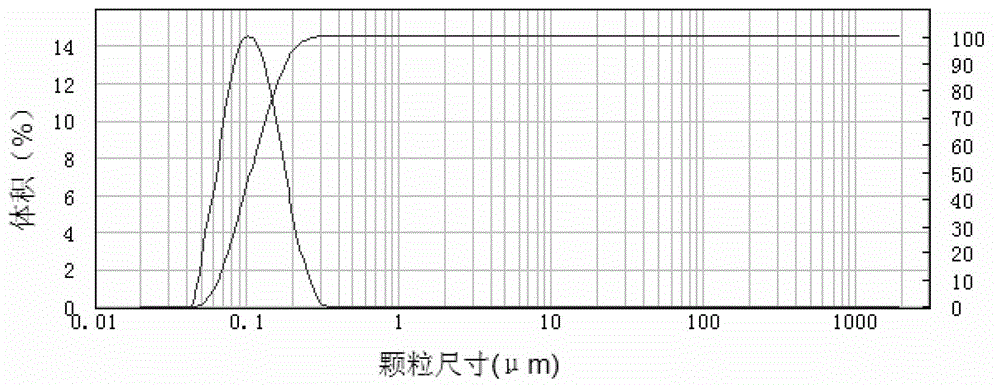

A carbon fiber and water-based technology, applied in the direction of carbon fiber, etc., can solve the problems that it is not suitable for use at low concentration and the particle size of the sizing agent is large, and achieve the effect of reproducibility and improvement of fiber performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the preparation method of the aqueous sizing agent that is used for carbon fiber in this embodiment is carried out according to the following steps:

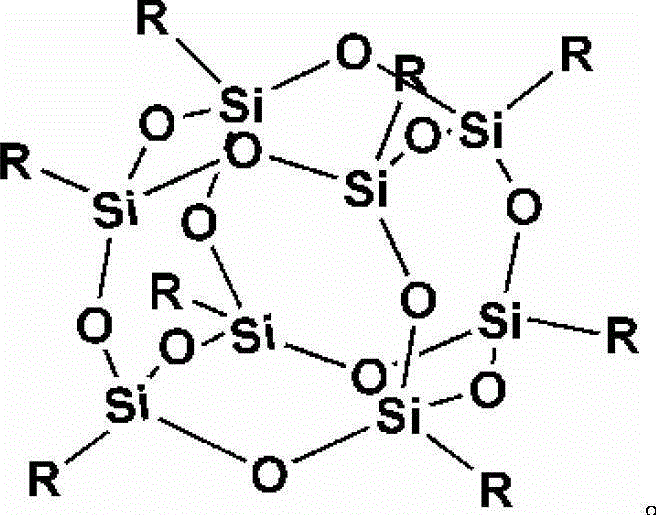

[0019] 1. Preparation of epoxy emulsifier: Add 30-35 parts by weight of epoxy resin and 4-7 parts by weight of POSS to the organic solvent, and add 1-2 parts by weight of coupling agent at 80-90°C React for 1 hour, cool down to 40-50°C, then add 50-60 parts by weight of polyethylene glycol for mixing, add 3-6 parts by weight of coupling agent at 80-90°C for 2 hours, then vacuumize and lower to room temperature , to obtain epoxy emulsifier;

[0020] 2. Mix the epoxy emulsifier with the epoxy resin under the condition of 40-70°C. The amount of the epoxy emulsifier is 2-3 times the mass of the epoxy resin, and then add deionized water until the phase transition is obtained. Water-based sizing agent for carbon fiber.

[0021] The POSS structure described in this embodiment is as follows:

[0022] ...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that the epoxy resin described in step 1 is epoxy resin EP-20. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 1 in that the coupling agent described in step 1 is diisocyanate or toluene diisocyanate. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com