Iron and steel enterprise quality information platform

A quality information and enterprise technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of product quality and defect analysis without unified methods and tools, hysteresis static management, single variable, etc., to achieve Fast search service, clear latitude, and completeness guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

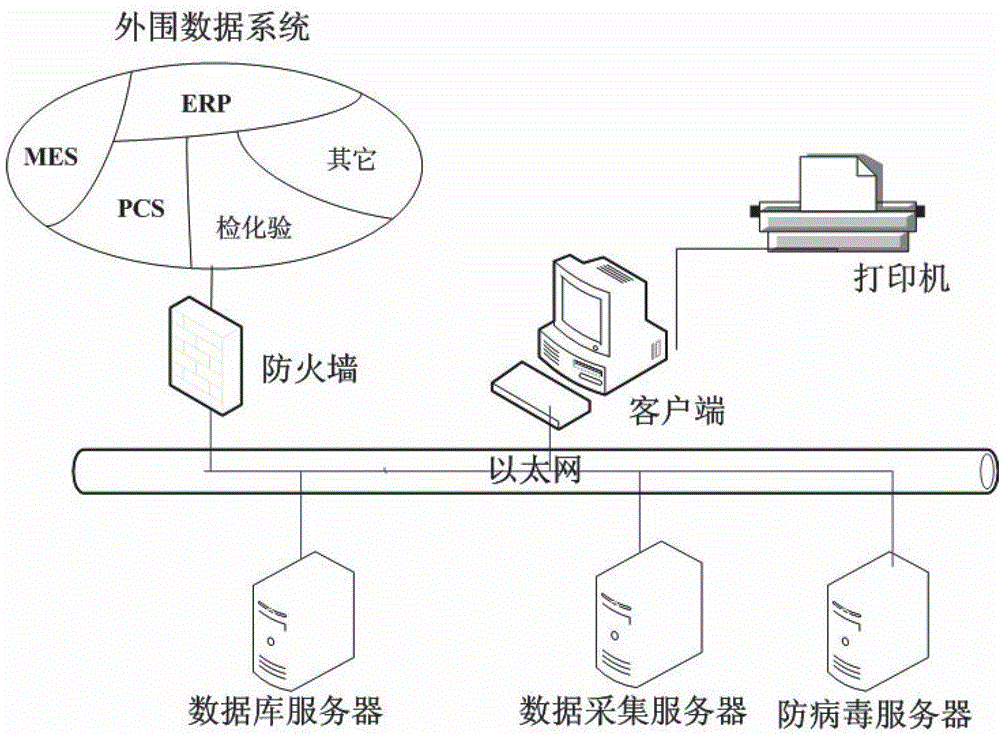

[0044] First, use the steel factory Ethernet to connect the peripheral data system, data acquisition server, database server, anti-virus server, client workstation, and run the data collector to normally collect data into the database.

[0045] The present invention includes hardware and software running on the hardware; the hardware includes a peripheral data system, a data acquisition server, a database server, a client computer, a printer connected to the client, and an antivirus server; the peripheral data system consists of The process control system PCS composed of PLC and DCS, the production execution system MES, the enterprise resource planning management system ERP, and the inspection and testing system are composed. The software includes data acquisition software, database software, and iron and steel enterprise quality information platform software.

[0046] 1. Implementation method of quality data preprocessing

[0047] Users can preprocess the quality data accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com