Tantalum decatungstate bar and production method for same

A production method and technology of tungsten rods, which are applied in the field of alloys, can solve the problems of low degree of microstructure breakage in the cast state, incomplete elimination of microstructures, and fracture failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

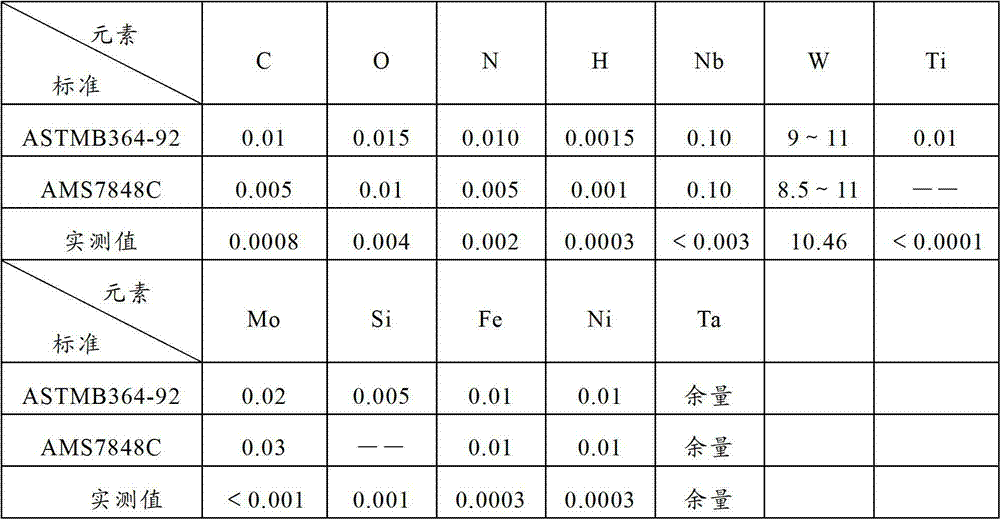

[0047] 1) The ingot of tantalum and tungsten is smelted three times in a vacuum electron beam furnace. The size of the ingot is φ153×150mm (diameter×length). The specific composition, specifications and standard comparison are shown in Table 1 below:

[0048] Table 1 Element content information table of tantalum ten tungsten ingots

[0049]

[0050] 2) Preheating

[0051] Use a box-type resistance furnace to heat the above-mentioned tantalum-ten-tungsten ingot. Set the temperature in the furnace to 180°C. When the temperature reaches the furnace loading time, keep it warm for 34 minutes. The low-temperature infrared temperature measurement is 165°C.

[0052] 3) Apply an anti-oxidation coating evenly on the surface of the ingot with a brush, with a thickness of about 3mm, and air-dry to room temperature.

[0053] 4) Medium frequency heating

[0054] Use medium-frequency induction coils with a diameter of φ180mm to heat the ingot coated with an anti-oxidation coating on the...

Embodiment 2

[0093] 1) The ingot of tantalum and tungsten is three times melted in a vacuum electron beam furnace. The size of the ingot is φ153×150mm (diameter×length). The specific composition, specifications and standard comparison are shown in Table 5 below:

[0094] Table 5 Example 2 tantalum ten tungsten ingot element content information table

[0095]

[0096] 2) Preheating: Preheat the tantalum and tungsten ingots with a box-type resistance furnace, heat the resistance furnace to 180°C, put the furnace into the temperature, and keep it warm for 40 minutes.

[0097] 3) Anti-oxidation coating: Evenly coat the surface of the preheated tantalum ten-tungsten ingot with a suspension of high-temperature glass powder plus water and water glass, with a coating thickness of about 3mm, and dry in the air.

[0098] 4) Medium-frequency induction heating: heat the tantalum ten-tungsten ingot obtained in step 3) with a φ180mm medium-frequency induction coil, heating with 20KW power for 4 minut...

Embodiment 3

[0137] 1) Melting tantalum and tungsten ingots to make the outer diameter ≥ φ150mm, chemical composition tungsten content 9~11wt%, sum of impurities ≤0.5wt%, single impurity ≤0.2wt%.

[0138] 2) Preheating: Preheat the tantalum and tungsten ingots with a box-type resistance furnace, heat the resistance furnace to 150°C, put the furnace into the warm furnace, and keep it warm for 40 minutes.

[0139] 3) Anti-oxidation coating: Evenly coat the surface of the preheated tantalum ten-tungsten ingot with a suspension of high-temperature glass powder plus water and water glass, with a coating thickness of about 2mm, and dry in the air.

[0140] 4) Medium-frequency induction heating: heat the tantalum-ten-tungsten ingot obtained in step 3) with a φ180mm medium-frequency induction coil, heating with 20KW power for 6 minutes, 40KW power for 7 minutes, 60KW power for 12 minutes, and 80KW power for 12 minutes. : 1400°C, the temperature difference from the center of the end face to the edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com