Refractory and rare noble metal pipe and preparation method thereof

A technology for rare and precious metals and pipes, applied in the field of material processing, can solve problems such as low processing costs, and achieve the effects of improving overall strength, preventing failure, and preventing easy cracking and failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a refractory and rare metal pipe provided in an embodiment of the present invention includes:

[0041] 1) material selection

[0042] Calculate and select the plate thickness according to the length and millimeter-level thickness requirements of the finished pipe, among which the inner diameter D of the finished pipe, the thickness H of the selected plate, and the thickness h of the finished pipe should satisfy the following relationship: 50H≤D≤15H, and h≤ 0.8H; select the plate that has been annealed.

[0043] 2) Bending processing and welding

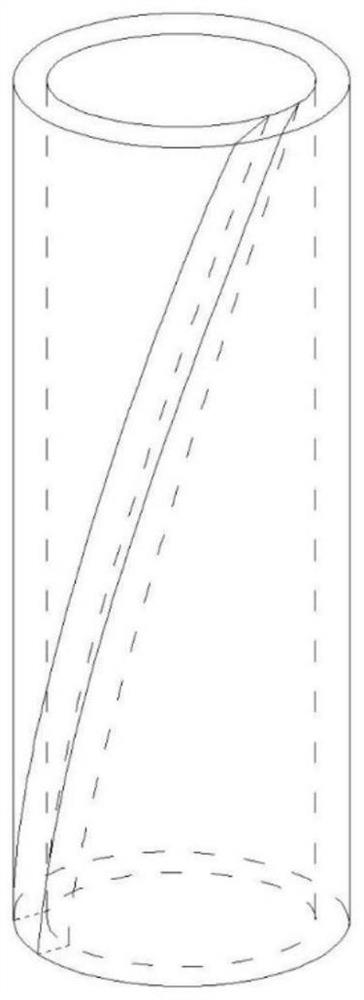

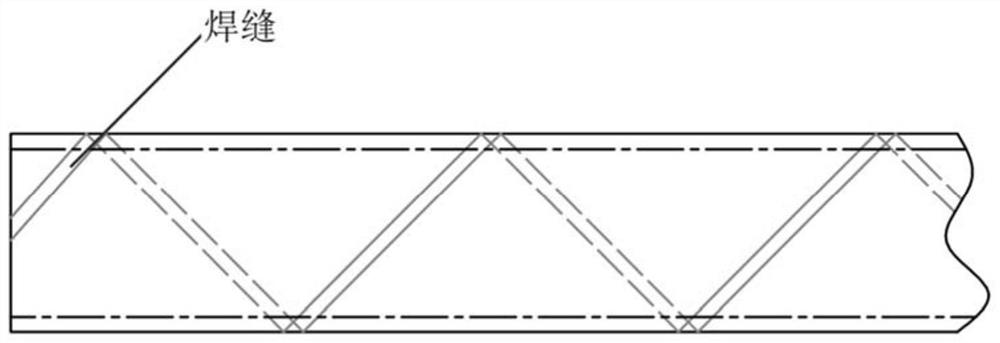

[0044]Choose different bending methods according to the calculated blank length and the length and width of the plate, and carry out machining. The bending method is divided into two types: for the plate whose length is not greater than 5m, you can choose the half-folding method, where the half-folding angle is 30-60°; For plates with a pipe length ≥ 5m, it is necessary to choose a spiral bending method...

Embodiment 1

[0054] Choose a 2mm thick molybdenum-lanthanum alloy to bend and weld the pipe to form it.

[0055] Step 1, prepare a molybdenum-lanthanum tube with a tube length of 1.5m, a diameter of 6cm and a thickness of 2mm, select a molybdenum-lanthanum alloy plate with a thickness of 3.5mm, and select the plate in an annealed state;

[0056] Step 2, choose a molybdenum-lanthanum alloy plate with a length of 1m and a width of 18cm to butt the two long sides along the tube axis at 30°, and perform laser and electron beam welding on the butt joint surface to form a welded seamless tube blank;

[0057] Step 3, shaping the welded seamless tube blank or seamless tube, simply grinding the weld seam, and annealing the welded seamless tube blank at 800°C for 40 minutes to eliminate the stress concentration in the weld seam;

[0058] Step 4: Roll the welded seamless pipe blank at 950°C after heat treatment, the initial rolling temperature should be increased by 60°C within the set temperature ra...

Embodiment 2

[0063] Select 0.8mm thick molybdenum-lanthanum alloy to bend and weld pipes for forming.

[0064] Step 1, preparing a molybdenum-lanthanum tube with a tube length of 1.2m, a diameter of 4cm, and a thickness of 0.8mm, selecting a molybdenum-lanthanum alloy plate with a thickness of 1.5mm, and selecting the plate in an annealed state;

[0065] Step 2, choose a molybdenum-lanthanum alloy plate with a length of 1m and a width of 12cm to butt the two long sides along the tube axis at 45°, and perform laser welding on the butt joint surfaces to form a welded seamless tube blank;

[0066] Step 3, shaping the welded seamless tube blank or seamless tube, simply grinding the weld seam, and annealing the welded seamless tube blank at 900°C for 20 minutes to eliminate the stress concentration in the weld seam;

[0067] Step 4, rolling the welded seamless tube blank prepared in step 3 at 950°C. The initial rolling temperature should be increased by 50°C, the rolling deformation should be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com