Tantalum ten tungsten rod production method

A production method and technology of tungsten rods, applied in the field of alloys, can solve the problems of low degree of fracture of the as-cast structure, incomplete elimination of the structure, and fracture failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

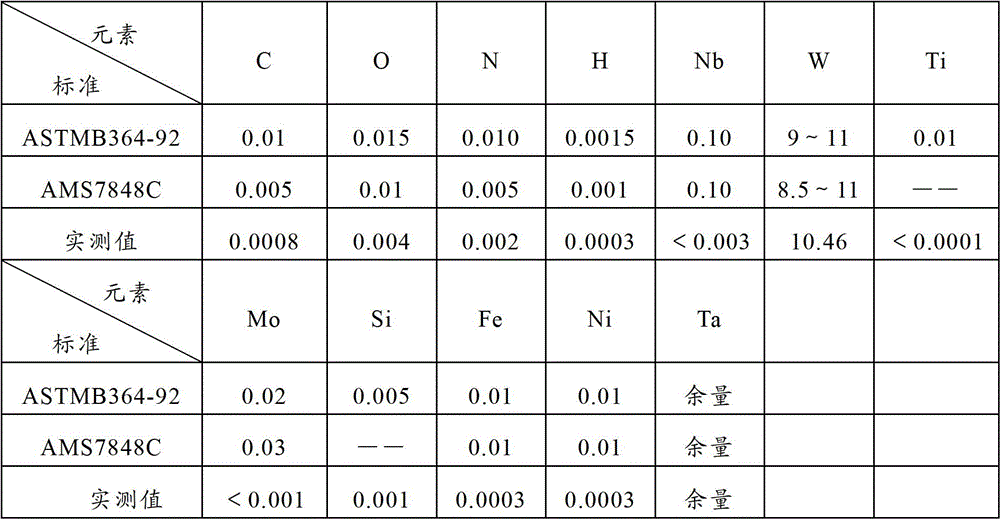

[0047] 1) The ingot of tantalum and tungsten is smelted three times in a vacuum electron beam furnace. The size of the ingot is φ153×150mm (diameter×length). The specific composition, specifications and standard comparison are shown in Table 1 below:

[0048] Table 1 Element content information table of tantalum ten tungsten ingots

[0049]

[0050] 2) Preheating

[0051] Use a box-type resistance furnace to heat the above-mentioned tantalum-ten-tungsten ingot. Set the temperature in the furnace to 180°C. When the temperature reaches the furnace loading time, keep it warm for 34 minutes. The low-temperature infrared temperature measurement is 165°C.

[0052] 3) Apply an anti-oxidation coating evenly on the surface of the ingot with a brush, with a thickness of about 3mm, and air-dry to room temperature.

[0053] 4) Medium frequency heating

[0054] Use medium-frequency induction coils with a diameter of φ180mm to heat the ingot coated with an anti-oxidation coating on the...

Embodiment 2

[0093] 1) The ingot of tantalum and tungsten is three times melted in a vacuum electron beam furnace. The size of the ingot is φ153×150mm (diameter×length). The specific composition, specifications and standard comparison are shown in Table 5 below:

[0094] Table 5 Example 2 tantalum ten tungsten ingot element content information table

[0095]

[0096] 2) Preheating: Preheat the tantalum and tungsten ingots with a box-type resistance furnace, heat the resistance furnace to 180°C, put it in the furnace, and keep it warm for 40 minutes.

[0097] 3) Anti-oxidation coating: Evenly coat the surface of the preheated tantalum ten-tungsten ingot with a suspension of high-temperature glass powder plus water and water glass, with a coating thickness of about 3mm, and dry in the air.

[0098] 4) Medium-frequency induction heating: heat the tantalum ten-tungsten ingot obtained in step 3) with a φ180mm medium-frequency induction coil, heating with 20KW power for 4 minutes, 40KW power ...

Embodiment 3

[0137] 1) Melting tantalum and tungsten ingots to make the outer diameter ≥ φ150mm, chemical composition tungsten content 9~11wt%, sum of impurities ≤0.5wt%, single impurity ≤0.2wt%.

[0138] 2) Preheating: Preheat the tantalum and tungsten ingots with a box-type resistance furnace, heat the resistance furnace to 150°C, put the furnace into the warm furnace, and keep it warm for 40 minutes.

[0139] 3) Anti-oxidation coating: Evenly coat the surface of the preheated tantalum ten-tungsten ingot with a suspension of high-temperature glass powder plus water and water glass, with a coating thickness of about 2mm, and dry in the air.

[0140] 4) Medium-frequency induction heating: heat the tantalum-ten-tungsten ingot obtained in step 3) with a φ180mm medium-frequency induction coil, heating with 20KW power for 6 minutes, 40KW power for 7 minutes, 60KW power for 12 minutes, and 80KW power for 12 minutes. : 1400°C, the temperature difference from the center of the end face to the edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com