Low-carbon and environmental-protection bulk emulsion explosive

An emulsion explosive, low-carbon and environmentally friendly technology, applied in the direction of explosives, etc., can solve the problems of poor adaptability, large gun smoke, etc., and achieve the effects of smooth transportation, reduced emissions, and reduced carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

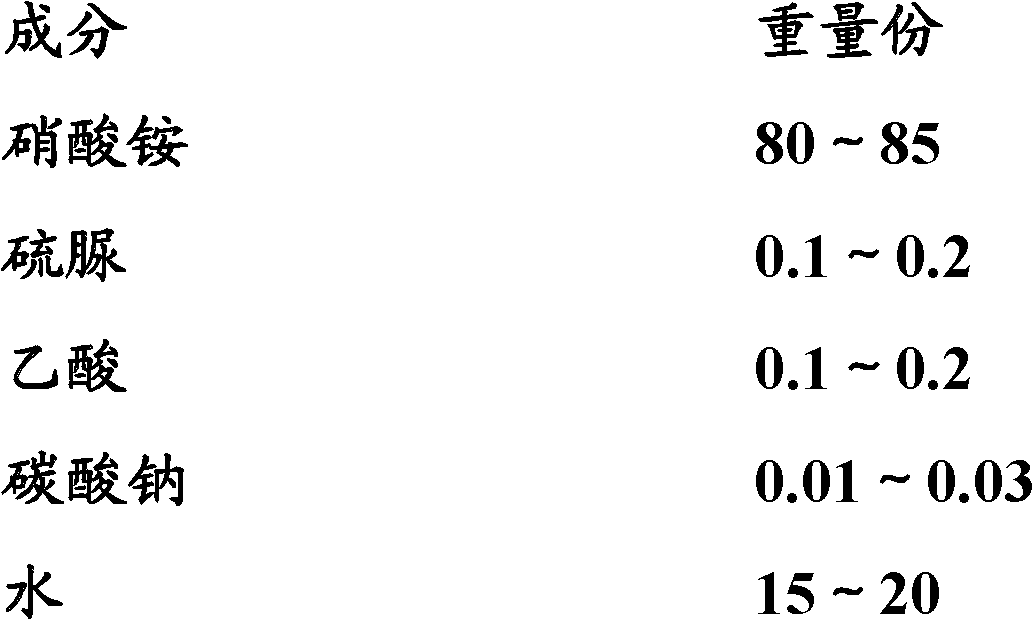

Method used

Image

Examples

Embodiment 1

[0028] Mix 72kg of ammonium nitrate, 0.2kg of thiourea, 0.1kg of acetic acid, 0.03kg of sodium carbonate, and 19.67kg of water at 80°C to form an aqueous oxidant solution, adjust the pH value to 3.5 with sodium hydroxide and acetic acid, and measure its crystallization point The temperature is 71°C, and the turbidity of the solution is 0.9NTU. Diatomaceous earth adsorbent is added to the solution, and the coarse filter and fine filter are sucked for 30 minutes to become a pure oxidant saline solution for later use; 2.3kg of LZ2820 emulsifier, 5.7kg of paraffin The oil is melted and mixed evenly at 70°C to obtain an oil phase; the oxidant salt solution obtained above and the oil phase are emulsified in an emulsifier to form a water-in-oil emulsified matrix, and the temperature is kept at 78°C, and the viscosity is measured as 25BU ; 0.09 kg of sodium nitrite, 0.11 kg of sodium thiocyanate, and 2.6 kg of water are configured into a sensitization liquid; the above emulsification m...

Embodiment 2

[0032] Mix 75kg of ammonium nitrate, 0.1kg of thiourea, and 17.9kg of water at 86°C to form an aqueous oxidant solution, adjust the pH value to 3.8 with sodium carbonate and acetic acid, and measure the crystallization point of 71°C, and the turbidity of the solution is 0.8NTU , add diatomaceous earth adsorbent to the solution, and filter through the coarse filter and the fine filter for 30 minutes to become a pure oxidant saline solution for later use; melt and mix 1.2kg of LZ2745 emulsifier and 5.8kg of engine oil at 70°C to obtain oil phase; the oxidant salt solution obtained above and the oil phase are emulsified in an emulsifier to form a water-in-oil emulsification matrix, and the temperature is maintained at 78 ° C, and the viscosity is 23 BU; 0.10 kg of sodium nitrite, sodium bicarbonate 0.11kg and 2.7kg of water are configured as a sensitization liquid; the above emulsification base and sensitizer are mixed to obtain a bulk emulsion explosive.

[0033] The test measur...

Embodiment 3

[0036] Mix 80kg of ammonium nitrate, 0.1kg of thiourea, 0.2kg of acetic acid, 0.01kg of sodium carbonate, and 14.69kg of water at 90°C to form an aqueous oxidant solution, adjust the pH value to 4.0 with sodium hydroxide and acetic acid, and measure its crystallization point as 70°C, the turbidity of the solution is 0.8NTU, add diatomaceous earth adsorbent to the solution, and filter through the coarse filter and the fine filter for 30 minutes to become a pure oxidant saline solution for later use; each 0.55kg of LZ2731 emulsifier and LZ2721 emulsifier, paraffin 3.9kg of oil was melted and mixed uniformly at 80°C to obtain an oil phase; the oxidant salt solution obtained above and the oil phase were emulsified in an emulsifier to form a water-in-oil emulsified matrix, and the temperature was kept at 90°C to measure its viscosity It is 15BU; 0.11kg of sodium nitrite, 0.09kg of sodium thiocyanate, and 3.0kg of water are configured into a sensitization liquid; the above emulsifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com