Method for producing methanol from semi-coke furnace tail gas

A technology of semi-coke tail gas and methanol synthesis, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., and can solve the problems of high cost and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

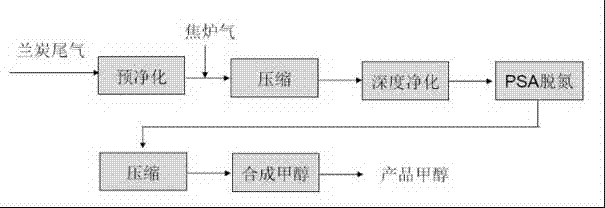

Image

Examples

Embodiment

[0027] The main composition (vol%) of the semi-coke tail gas in this embodiment is: H 2 : 23.9, CH 4 : 7.7, CO: 15.4, CO 2 : 9.5, C n h m : 2.4, N 2 : 40.6, O 2 : 0.5. The gas volume is 1000kmol, and the temperature is 40°C.

[0028] (1) Pre-purification

[0029] A dry purification temperature swing adsorption method is used to remove macromolecular impurities such as tar, naphthalene, benzene and dust in the semi-coke tail gas, and a rough purified semi-coke tail gas is obtained.

[0030] (2) Mix coke oven gas with high hydrogen-to-carbon ratio gas source and semi-coke tail gas, so that the hydrogen-to-carbon ratio in the raw material entering the methanol synthesis process satisfies the following expression f=(H 2 -CO 2 ) / (CO+CO 2 )=2.05~2.15.

[0031] The main composition (vol%) of coke oven gas is: H 2 :58,CH 4 : 26, CO: 7.1, CO 2 : 2.7, C n h m : 2.5, N 2 : 3.2, O 2 : 0.5. The gas volume is 1145kmol, and the temperature is 40°C.

[0032] (3) Compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com