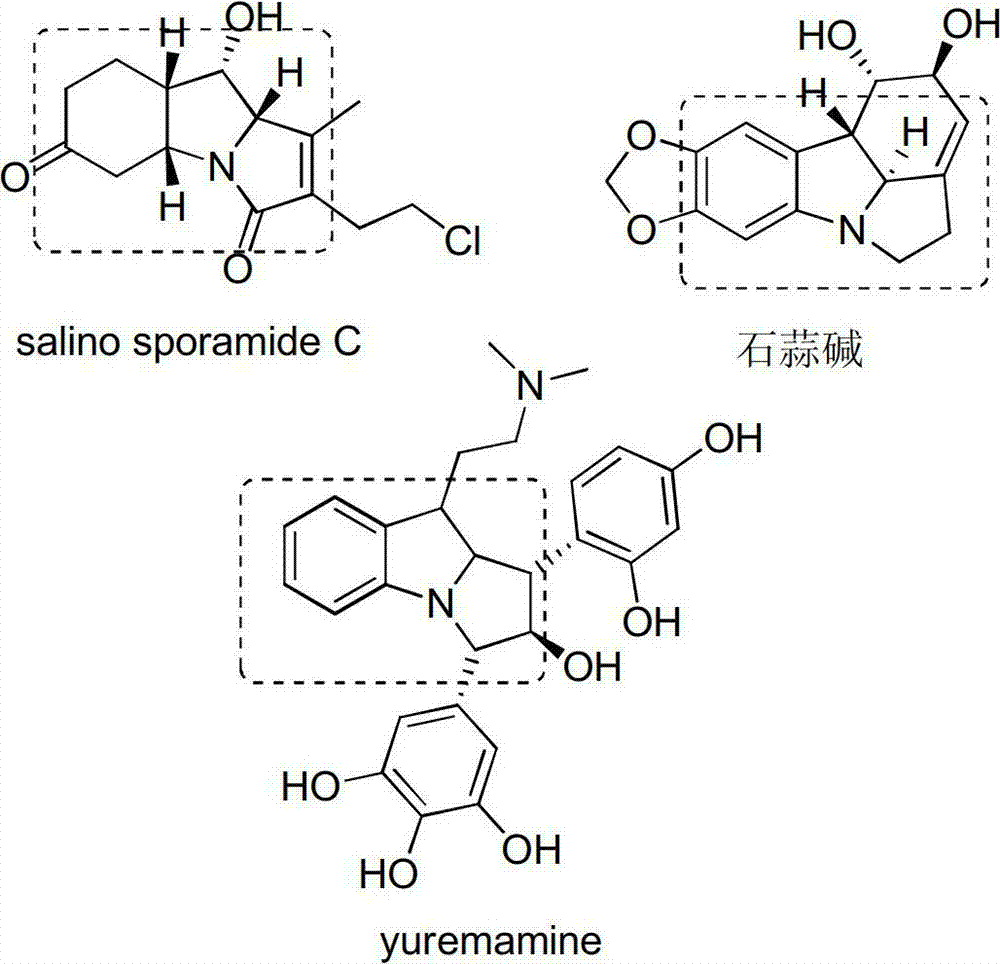

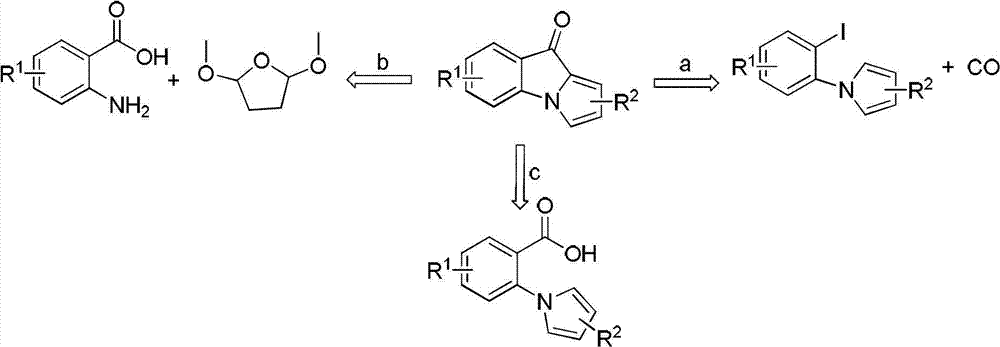

Synthetic method of pyrrole fused-ring 3-indolone type compounds

A synthesis method and compound technology, applied in organic chemistry and other fields, can solve problems such as poor atom economy, high potential danger, and difficulty in raw material construction, and achieve the effect of short route, high application value, and promotion of deep-level expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

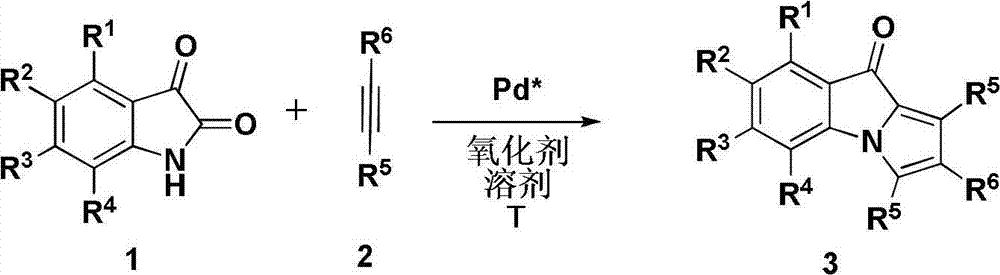

Method used

Image

Examples

Embodiment 1

[0026]

[0027] Under the protection of an inert gas, the fused ring isatin compound 1 (0.20mmol) and the alkyne compound 2a (1.00mmol) were dissolved in acetonitrile / 1,4-dioxane (2.00mL) (v / v=1:1 ), add palladium acetate (0.02mmol), silver acetate (0.40mmol), the reaction system was stirred for 12 hours at 100°C, and detected by TLC. After drying, the solvent was removed by spinning to obtain a crude product, and the product 3a was obtained by flash column chromatography with a yield of 63% (recovered yield 85%). 1 H NMR (500MHz, CDCl 3 ): δ=7.76(t, J=8.0Hz, 2H), 7.63(d, J=8.0Hz, 1H), 7.56-7.54(m, 2H), 7.46(t, J=8.5Hz, 1H), 7.38 -7.30(m, 8H), 7.20-7.17(m, 3H), 7.02(dd, J=7.0, 2.0Hz, 2H), 6.81-6.77(t, J=8.0Hz,, 1H), 6.67(d, J = 8.5Hz, 1H); 13 C NMR (125MHz, CDCl 3 ):δ=179.85,144.00,138.77,136.91,134.11,132.69,132.23,131.73,131.56,131.28,130.24,129.92,129.72,129.49,129.29,128.76,128.49,128.31,128.10,127.22,127.08,126.20,125.58, 121.40, 120.06; calculated HRMS (ESI) C 3...

Embodiment 2

[0029]

[0030] The operation steps are the same as in Example 1, and the yield is 62% (the recovered yield is 91%). 1 H NMR (500MHz, CDCl 3 ): δ=7.76-7.72(m, 2H), 7.62(d, J=8.5Hz, 1H), 7.54(dd, J=7.0, 2.0Hz, 2H), 7.26(d, J=1.5Hz, 1H) , 7.25(d, J=1.5Hz, 2H), 6.93(d d, J=7.0, 2.0Hz, 2H), 6.89(t, J=2.0Hz, 2H), 6.84(dd, J=7.0, 2.5Hz, 2H), 6.77(d, J=8.5Hz, 1H), 6.76-6.74(m, 1H), 3.85(s, 3H), 3.81(s, 3H), 3.78(s, 3H); 13 C NMR (125MHz, CDCl 3 ):δ=179.59,160.77,160.07,158.79,143.87,138.71,137.21,133.01,132.63,132.42,131.70,129.38,129.28,129.02,127.96,126.76,126.72,126.13,125.75,125.07,124.34,121.47,120.11, 114.97, 114.06, 113.77, 55.88, 55.67, 55.59; HRMS (ESI) calculated value C 36 h 27 NNaO 4 [M+Na] + 560.1832, actual value 560.1837..

Embodiment 3

[0032]

[0033] The operation steps are the same as in Example 1, and the productive rate is 52% (the productive rate is 79% after raw material recovery). 1 H NMR (500MHz, CDCl 3 ): δ=7.78(d, J=8.5Hz, 1H), 7.73(d, J=8.0Hz, 1H), 7.67(d, J=8.0Hz, 1H), 7.45-7.42(m, 2H), 7.39 -7.36(m, 3H), 7.30-7.26(m, 4H), 7.22-7.20(m, 2H), 6.93-6.89(m, 3H), 6.72(d, J=8.5Hz, 1H); 13 C NMR (125MHz, CDCl 3 ):δ=179.78,143.82,138.92,136.33,135.39,134.87,133.70,132.98,132.44,132.11,131.47,130.73,130.59,130.01,129.64,129.57,129.19,128.82,128.66,128.61,128.47,127.57,126.47, 125.20, 121.25, 120.15; HRMS (ESI) calculated value C 33 h 19 Cl 3 NNaO[M+Na] + 572.0346, actual value 572.0353..

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com