Post-treatment method of copper indium gallium selenide absorbing layer and solar cell preparation method based on it

A technology of copper indium gallium selenide and thin-film solar cells, which is applied in the field of new energy, can solve the problems of affecting the characteristics of CdS/CIGS heterojunction, the increase of CdS/CIGS interface states, and the inability to form effective connections, so as to achieve simple and reliable equipment and promote The effect of depth expansion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

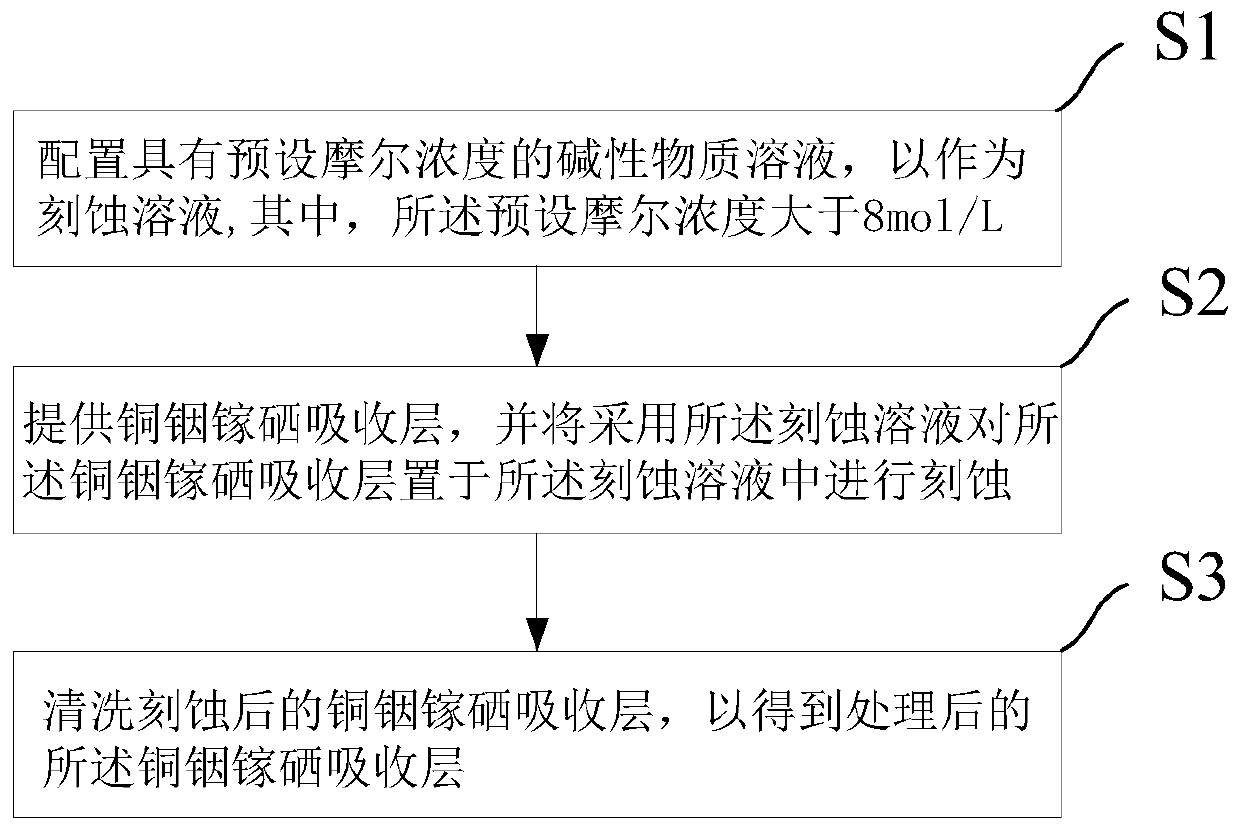

[0061] Such as Figure 1~6 As shown, the present invention provides a post-treatment method for the absorbing layer of a copper indium gallium selenide thin film solar cell, comprising the steps of:

[0062] 1) configuring an alkaline substance solution with a preset molar concentration as an etching solution, wherein the preset molar concentration is greater than 8 mol / L;

[0063] 2) providing a copper indium gallium selenide absorption layer, and using the etching solution to etch the copper indium gallium selenide absorption layer, so as to modify the surface of the copper indium gallium selenide absorption layer;

[0064] 3) Cleaning the etched CIGS absorption layer to obtain the CIGS absorption layer after treatment.

[0065] The post-treatment method of the absorption layer of the copper indium gallium selenium thin film solar cell of the present invention will be described in detail below in conjunction with specific drawings.

[0066] Such as figure 1 As shown in S1...

Embodiment 2

[0106] This embodiment provides a method for preparing a copper indium gallium selenide thin film solar cell, comprising the following steps:

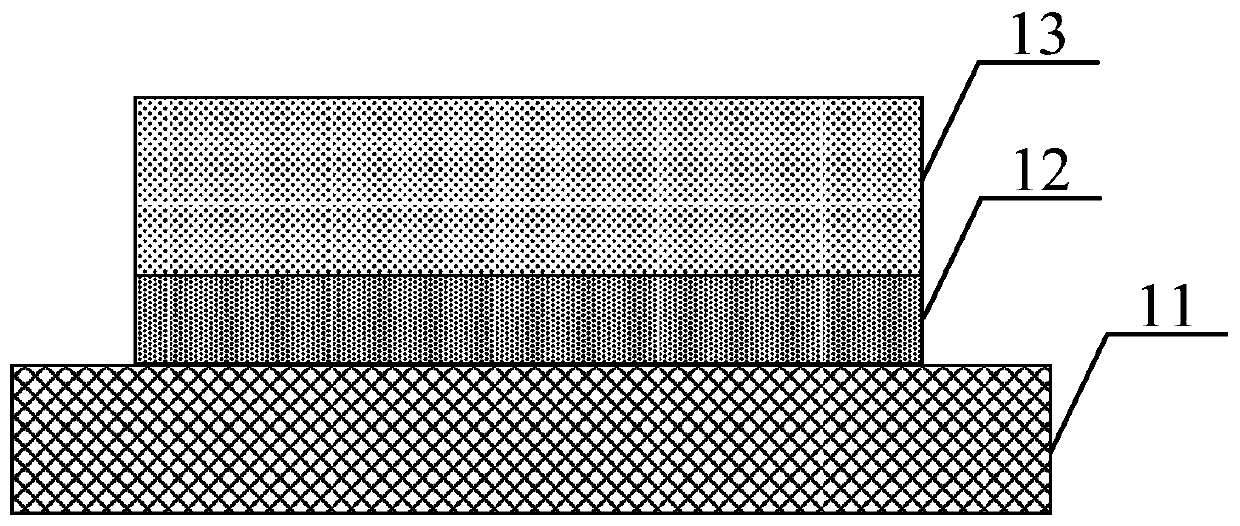

[0107] 1) providing a substrate 11, and forming a first electrode layer 12 on the substrate;

[0108] 2) forming a copper indium gallium selenide absorption layer 13 on the surface of the first electrode layer 12;

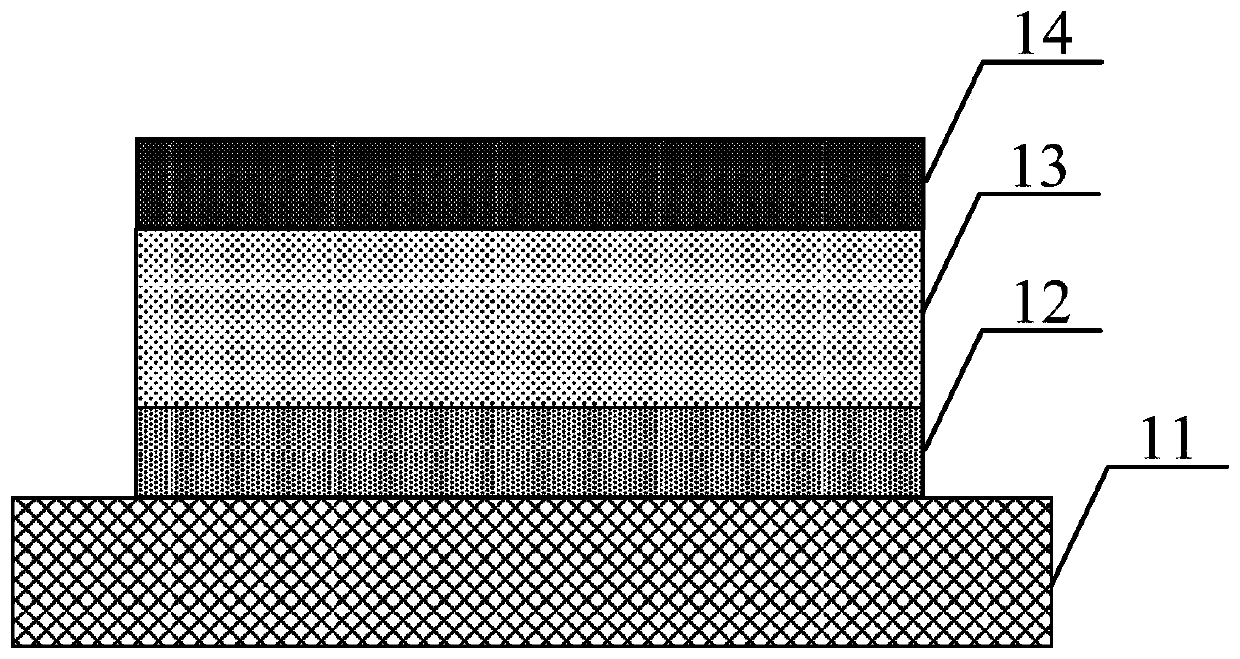

[0109] 3) post-processing the CIGS absorption layer 13 by any one of the methods in the embodiment;

[0110] 4) forming a window layer 15 on the surface of the obtained structure in step 3);

[0111] 5) Forming the second electrode layer 16 on the surface of the window layer 15 .

[0112] Specifically, when the post-processing method of forming a buffer layer of the absorbing layer is adopted, the buffer layer 14 (such as a CdS buffer layer) will be formed on the surface of the copper indium gallium selenide absorbing layer 13, and the window layer 15 is formed on The buffer layer 14 surface.

[0113] As an example, the...

Embodiment 3

[0124] This embodiment three provides another method for preparing a copper indium gallium selenide thin-film solar cell. The difference between this embodiment three and embodiment two is:

[0125] In step 2-2), a batch of CIGS absorbing layers with [Cu] / [In+Ga] of about 0.92 were prepared, with a thickness of about 1.2 μm. In addition, the prepared CuInGaSe absorbing layers were stored in dry Cabinet for 30min (vacuum degree is about 10 2 Pa level), 0.5 days in the air, 1 day in the air, 2 days in the air.

[0126] It should be noted that, compared with the copper indium gallium selenide thin film solar cell prepared by the above method of this embodiment, the open circuit voltage can be increased by about 30mV, and the fill factor can be increased by 3.6%. , the absolute value of the battery conversion efficiency increases by 1.2%. In addition, if Figure 6 As shown, it provides the copper indium gallium selenide thin film solar cell prepared by the method of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com