Method for preparing crystalline polyether-ether-ketone foam material

A polyetheretherketone and foam material technology is applied in the field of preparation of high-performance crystalline polyetheretherketone foam materials, and can solve the problems of restricting cell growth, difficult to control the morphology of polyetheretherketone foam, and reducing solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, the dried polyether ether ketone particles (MFI=23g / 10min, crystallinity 31.3%) were placed in a high-temperature autoclave, and the cavity was sealed. Use a vacuum pump to remove the air and moisture in the kettle, and then use 500-700psi low-pressure CO 2 The gas is repeatedly flushed 3 to 4 times to ensure that there is no other gas remaining in the kettle. Then inject CO with a high-pressure metering pump 2 Gas, control the constant pressure to 5MPa, increase the temperature of the kettle to 340°C, and the saturation time is 1h; then quickly reduce the pressure to normal pressure through the pressure reducing valve, the depressurization rate is 20MPa / s, and quickly place the reactor in cold water Cool in medium to fix the cell structure, so as to obtain foam samples.

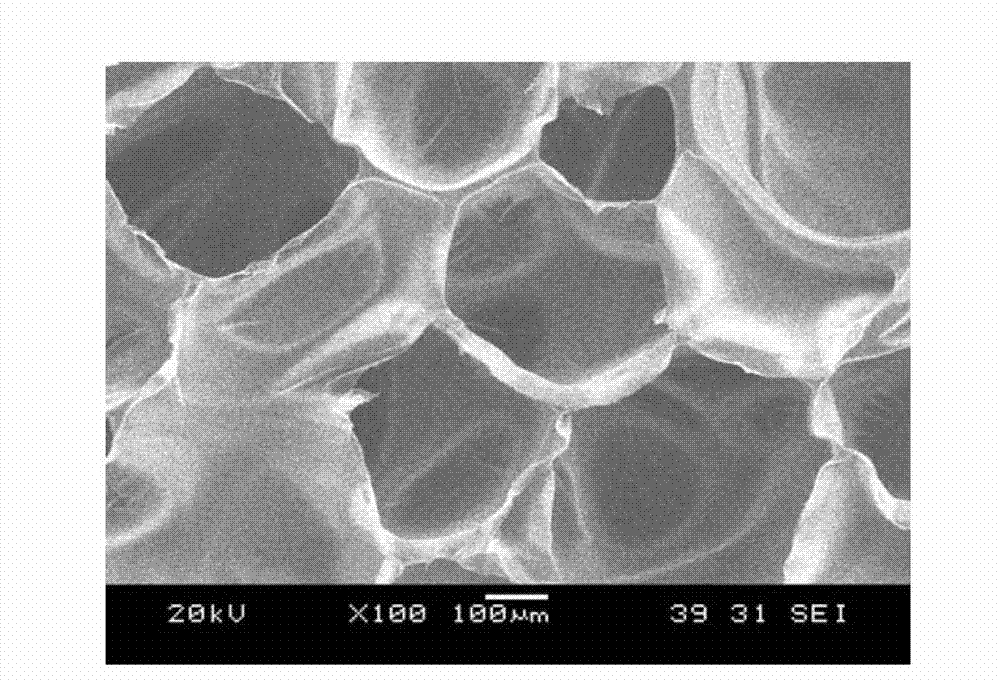

[0026] The samples were taken out for scanning electron microscope analysis of their section, such as figure 1 As shown, the foamed polyether ether ketone sample has a closed-cell structure ...

Embodiment 2

[0028] First, the dried polyether ether ketone particles (MFI=23g / 10min, crystallinity 31.3%) were placed in a high-temperature autoclave, and the cavity was sealed. Use a vacuum pump to remove the air and moisture in the kettle, and then use a 500-700psi low-pressure CO 2 The gas is repeatedly flushed 3 to 4 times to ensure that no other gas remains in the kettle. Then inject CO with a high-pressure metering pump 2 Gas, the control constant pressure is 10MPa. Raise the temperature of the kettle to 335°C, and the saturation time is 0.5h; then quickly reduce the pressure to normal pressure through the pressure reducing valve at a rate of 20MPa / s, and quickly place the reaction kettle in cold water to cool to fix the cell structure , to obtain foam samples.

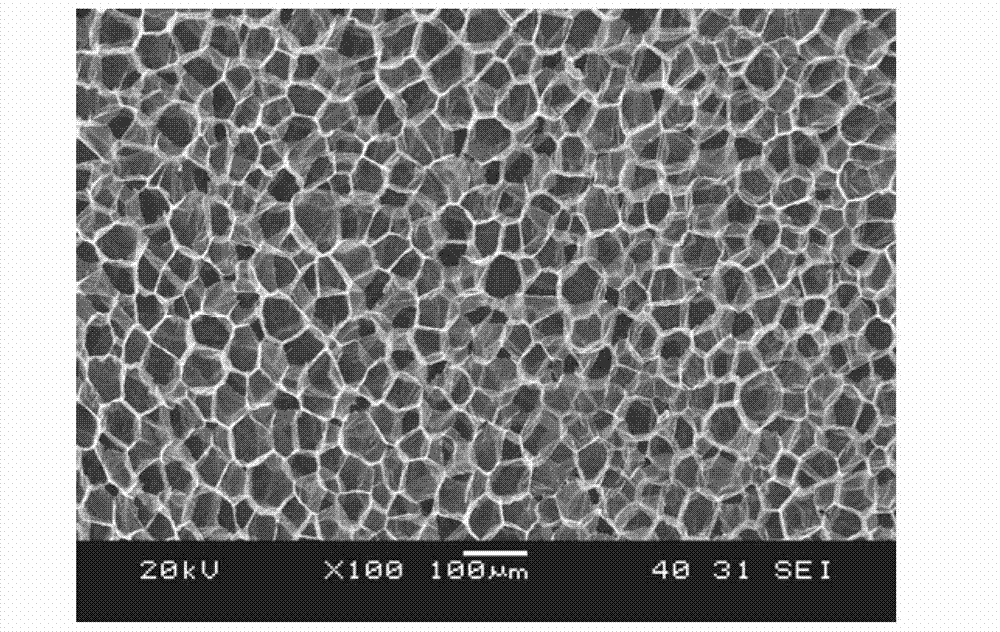

[0029] The samples were taken out for scanning electron microscope analysis of their section, such as figure 2 As shown, the foamed polyether ether ketone sample has a closed-cell structure with a pore size of 30-80 μm a...

Embodiment 3

[0031] First, the dried polyether ether ketone particles (MFI=23g / 10min, crystallinity 31.3%) were placed in a high-temperature autoclave, and the cavity was sealed. Use a vacuum pump to remove the air and moisture in the kettle, and then use a 500-700psi low-pressure CO 2 The gas is repeatedly flushed 3 to 4 times to ensure that no other gas remains in the kettle. Then inject CO with a high-pressure metering pump 2 Gas, the control constant pressure is 15MPa. Raise the temperature of the kettle to 337.5°C, and the saturation time is 1h; then quickly reduce the pressure to normal pressure through the pressure reducing valve at a rate of 20MPa / s, and quickly place the reactor in cold water to cool the cell structure. Obtain a foam sample.

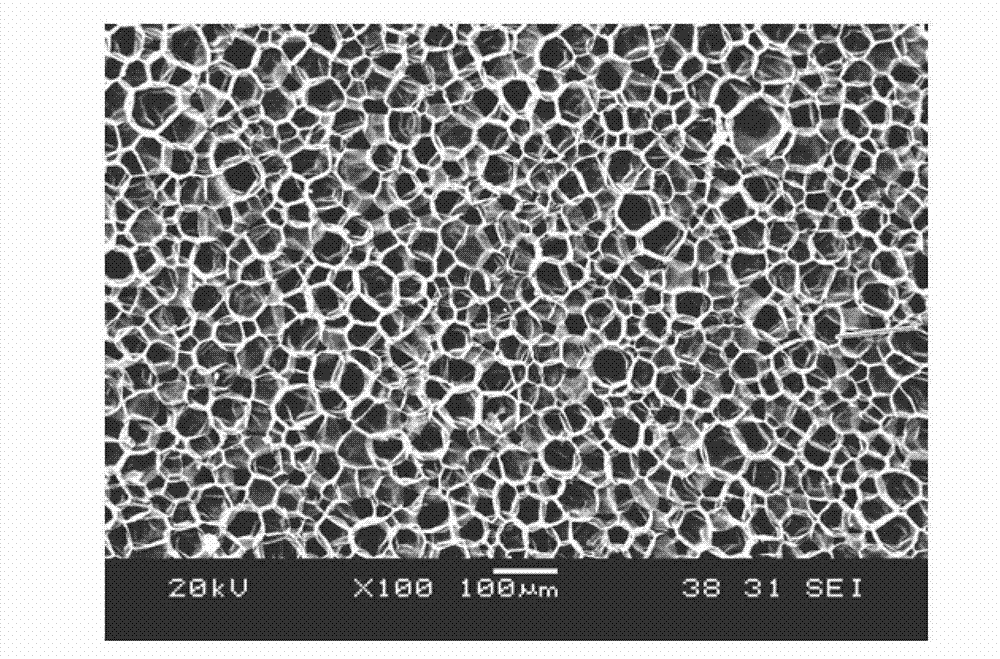

[0032] The samples were taken out for scanning electron microscope analysis of their section, such as image 3 As shown, the foamed polyetheretherketone sample has a closed-cell structure with a pore size of 10-70 μm and a pore density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com