Push-pull optical fiber displacement sensor with compliant cylinder structure and optical fiber strain gauge

A technology of displacement sensor and optical fiber strain, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve problems such as electromagnetic interference, output nonlinearity, and complex connection circuits, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

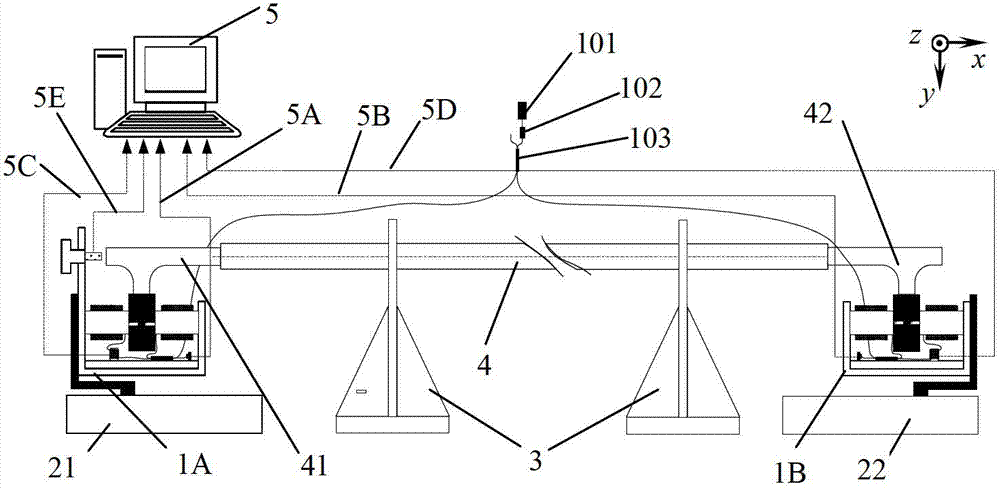

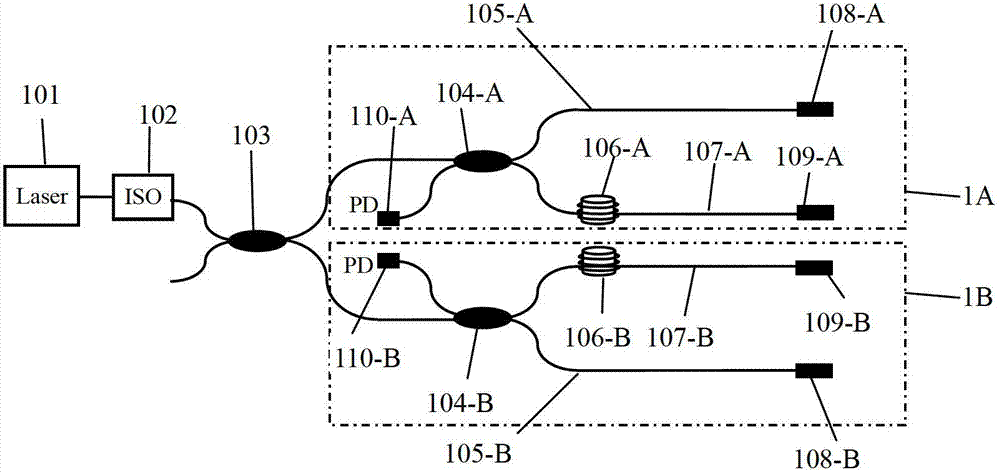

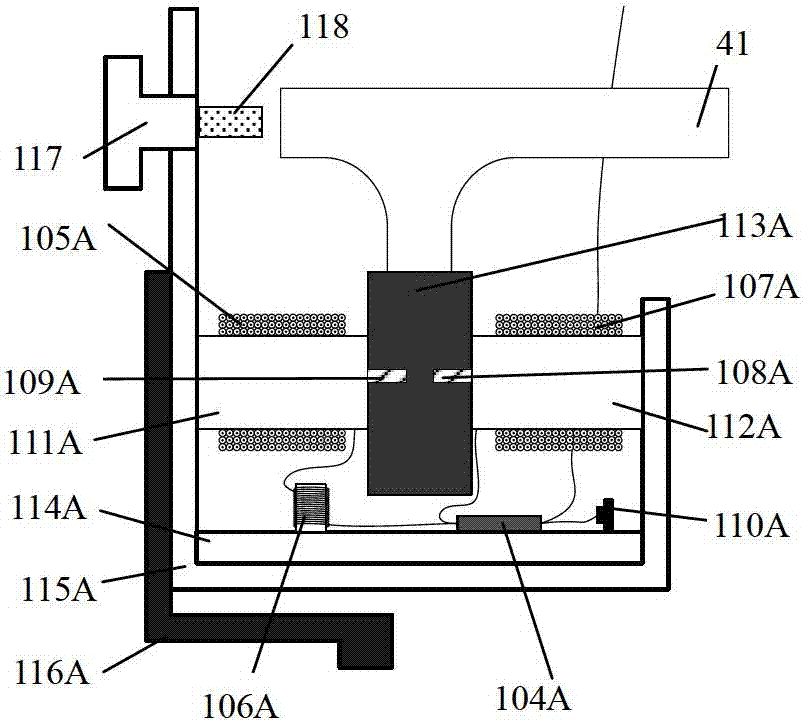

[0051] combine figure 1, the push-pull optical fiber strain gauge with variable cylindrical structure is composed of displacement sensors 1A, 1B, measuring baseline rod 4, suspension system 3, measuring bedrock 21, 22, and measuring control, signal recording and processing system 5, fixed on the 1. The first optical fiber displacement sensor 1A on the bedrock 21 is connected to one end 41 of the measurement baseline 4; the second optical fiber displacement sensor 1B fixed on the second bedrock 22 is connected to the other end 42 of the measurement baseline 4; the first optical fiber displacement The sensor 1A and the second optical fiber displacement sensor 1B are connected to the measurement control, signal recording and processing system 5 through signal connection lines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com