Plate-type working electrode and method for manufacturing same

A working electrode, flat-plate technology, applied in the field of electrodes, can solve the problems of environment and operator injury, limit the application of electrochemical detection, unsatisfactory reproducibility, etc., achieve low cost, good reproducibility of results, and production The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

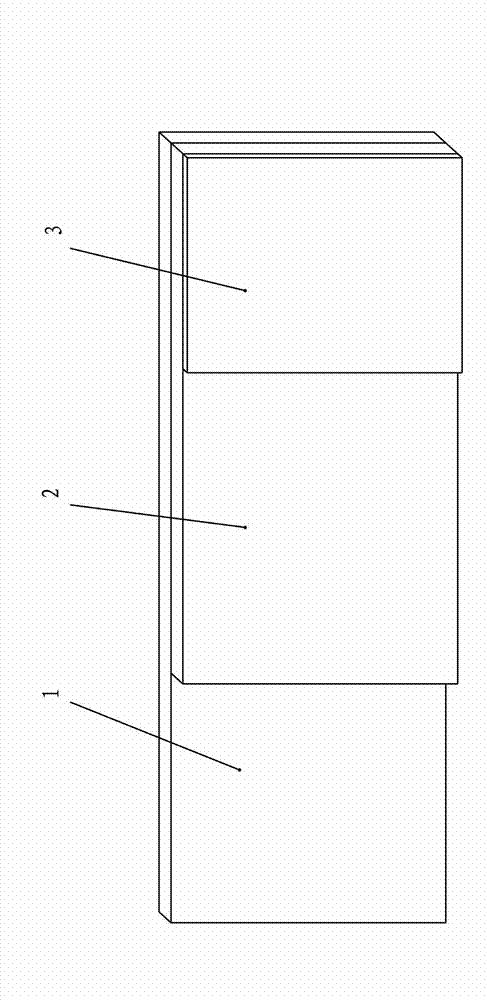

[0020] Such as figure 1 As shown, the flat plate working electrode of the present invention includes a flat conductive layer 1, a polymer conductive film 2, and an adhesive tape layer 3. The flat conductive layer 1 is made of ITO glass, conductive metal sheet or graphite sheet, and its width is 0.5cm~ 1cm, the length is 1.5cm ~ 2.5cm. The conductive metal sheet is preferably silver sheet or copper sheet. The polymer conductive film 2 can be a polymer silver conductive film or a polymer carbon conductive film or other types of polymer conductive films, for example, a double-sided conductive carbon tape produced by the American API company can be used. Tape layer 3 adopts waterproof tape with insulating properties, such as common scotch tape. The polymer conductive film 2 is pasted on the flat conductor layer 1, and the tape layer 3 is pasted on one end of the polymer conductive film 2. The polymer conductive film 2 covers 1 / 2 to 2 / 3 of the flat conductor layer, and the tape l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com