Polarized light 3D (three dimensional) lens and production method therefor

A technology of 3D lenses and manufacturing methods, applied in chemical instruments and methods, optics, polarizing components, etc., to achieve good bonding effect, convenient use, and stable 3D effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

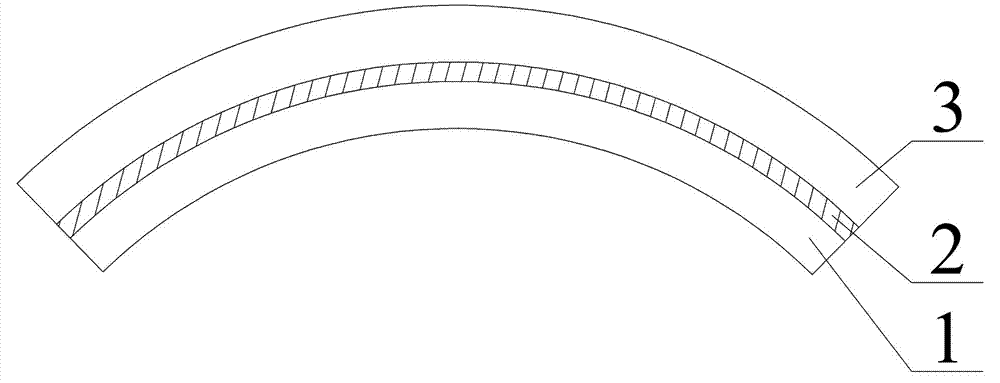

[0027] The polarizing 3D film is composed of a PVA polarizing film on the inner layer, a retardation film in the middle and a triacetate cellulose film (TAC) on the outer layer, and is coated on both sides of the retardation film with acrylic heat-sensitive adhesive, and then used The roller pressing machine sticks the PVA polarizing film and the TAC film on both sides of the retardation film to form a polarizing 3D composite film. Straighten the four sides of the polarized 3D composite film, immerse in the binder solution - polyvinyl alcohol resin containing acetyl ethyl and methylol melamine aqueous solution, carry out surface chemical treatment at room temperature, and then place it at 50-60°C for After drying, chemically reactive groups can be obtained on both sides of the polarizing 3D film.

[0028] The preparation of the above polyvinyl alcohol resin containing acetyl ethyl group and aqueous solution of methylol melamine: under the temperature condition of 30°C, 10 part...

Embodiment 2

[0033] The polarizing 3D film consists of a PVA polarizing film on the inner layer, a retardation film in the middle and a PVA film on the outer film, and is coated on both sides of the retardation film with an adhesive, dried at 40-60°C, and then rolled The machine sticks PVA polarizing film and TAC film on both sides of the retardation film to form a polarizing 3D composite film. Here the polarized 3D composite film does not require additional chemical treatment.

[0034] Fix the polarized 3D film on the fixed frame of the film pulling machine, put it into the fixed tank of the constant temperature and humidity oven, control the temperature at 50°C, and the humidity at 65%, take it out after about 10 minutes, put it in the aluminum film, and put it in a dust-free drying oven , control the temperature at 80°C and the humidity at 35%, take it out after 10 minutes.

[0035] Install the lower mold in the prepared plastic ring, then install the polarizing 3D film, and finally cl...

Embodiment 3

[0038] Polarizing 3D film is composed of PVA polarizing film on the inner layer, retardation film in the middle and cellulose acetate propionate film (TAC) on the outer film, and is coated on both sides of the retardation film with acrylic heat-sensitive adhesive, and then rolled by a roller press Lay PVA polarizing film and TAC film on both sides of the retardation film to form a polarizing 3D composite film; straighten the four sides of the polarizing 3D composite film, immerse in the adhesive solution—polyurethane glue, and carry out surface chemical treatment at room temperature , and then cured in air at 30-50°C with a humidity of 60%, and chemically reactive groups can be obtained on both sides of the polarized 3D composite film.

[0039] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com