Method for manufacturing large hollow steel ingots by forced cooling with single sleeves

A technology for forced cooling and hollow steel, applied in the field of manufacturing large-scale hollow steel ingots, can solve the problems of complex core structure production, complex assembly, high labor intensity of workers, etc., and achieve the effect of shortening smelting cycle, reducing power consumption and high cooling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

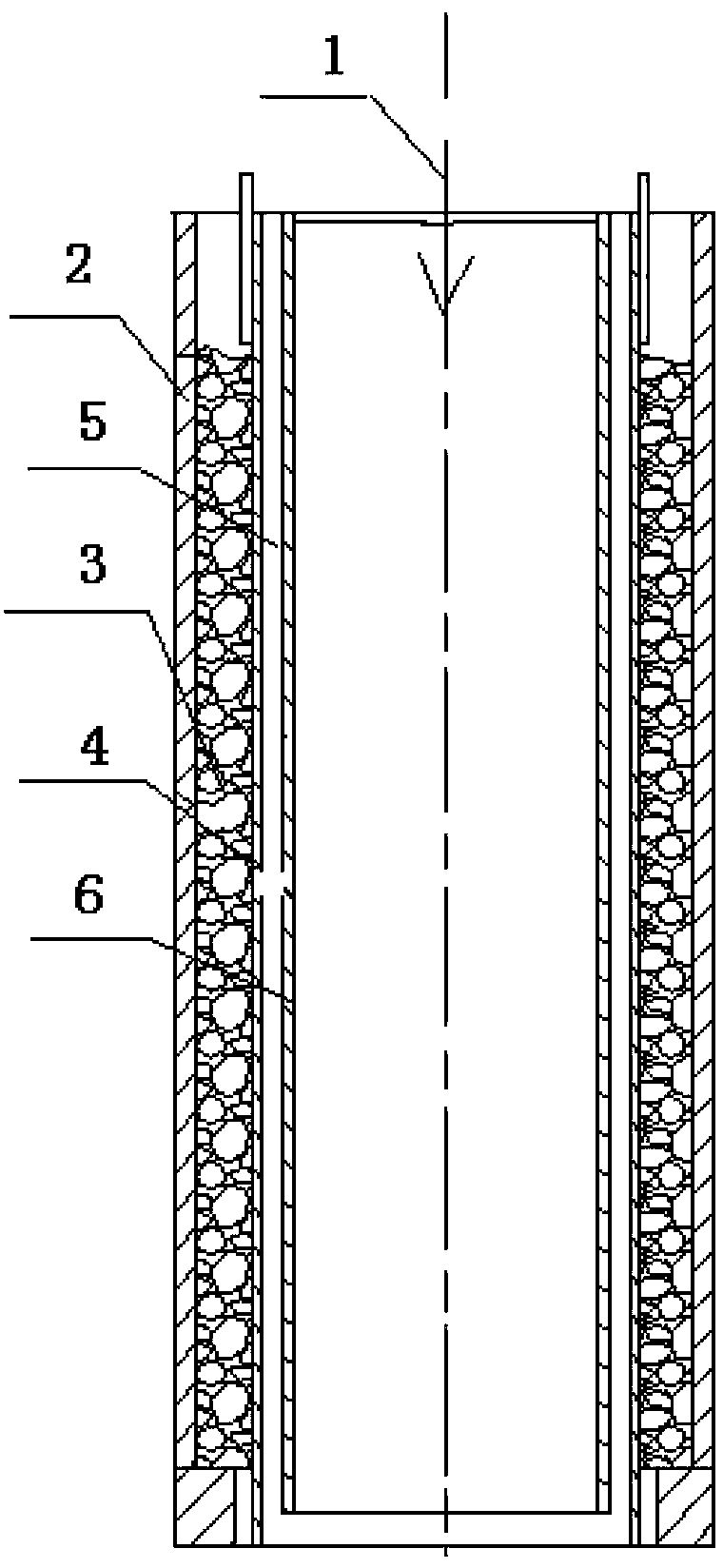

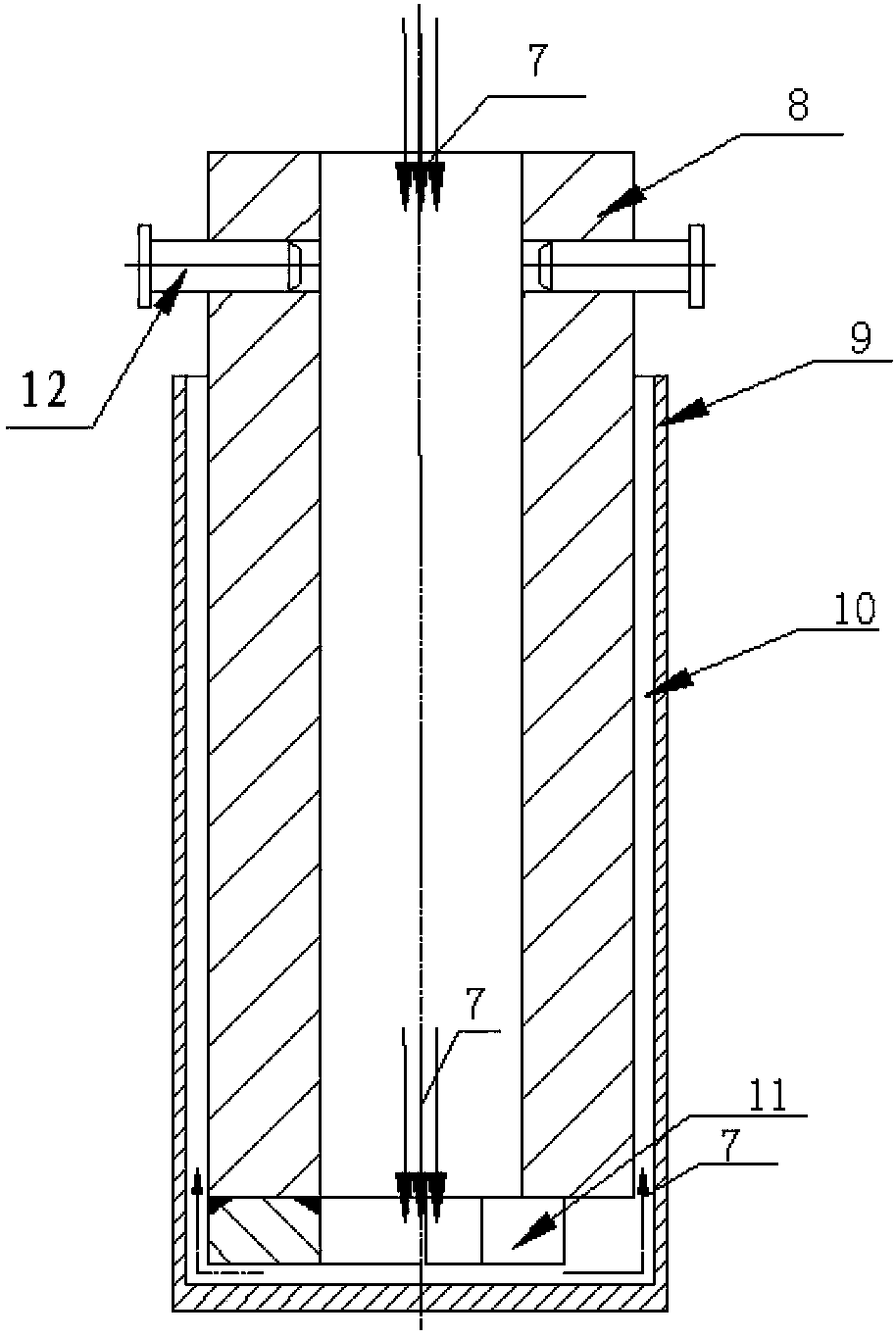

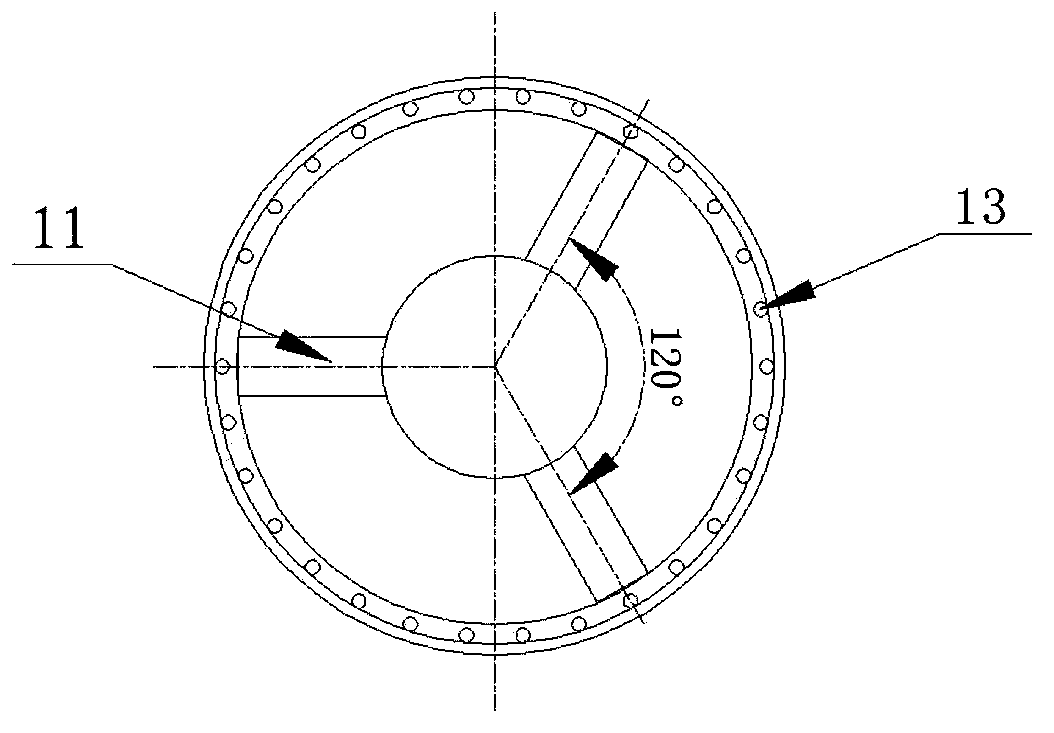

[0024] It consists of a single-layer sleeve core structure device, mixed gas forced cooling technology and gating system device. The horizontal channel of molten steel is installed on the lower chassis, the upper chassis is installed above the horizontal channel of molten steel, and the core is installed in the center of the upper chassis; the single-layer sleeve is located outside the core, and the outside of the sleeve is coated with high-temperature resistant Amercoat873AL silver paint, which is in contact with the cooling gas The surface is coated with Amercoat873AL black paint; several support ribs are welded inside the sleeve, and the bottom of the support ribs is 20-60mm away from the bottom end of the sleeve; a steel ingot mold is installed on the outer edge of the upper chassis, an insulation cap is installed on the steel ingot mold, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com