Preparation method of indium oxide nanorod ordered aggregate

A technology of nanorods and aggregates is applied in the field of preparation of indium oxide nanorod ordered aggregates, which can solve the problems of generating harmful gas, complicated operation and high cost, and achieves the effects of protecting the environment, simple process and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of ordered aggregates of indium oxide oxyhydroxide (InOOH) nanorods

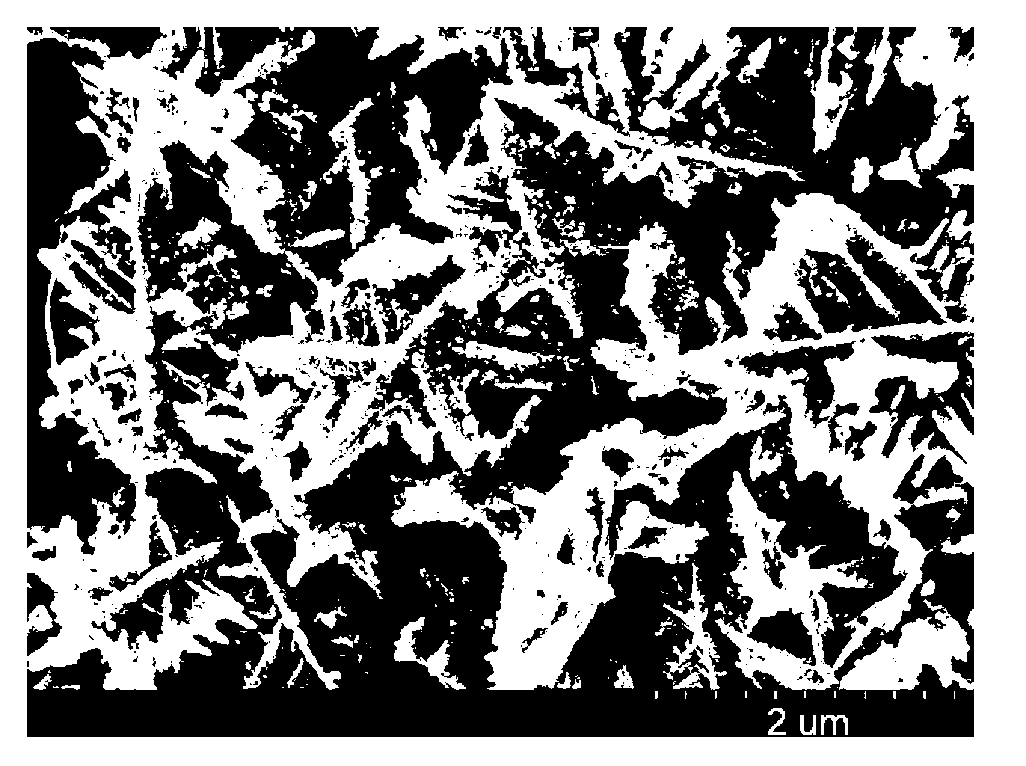

[0033] Under the condition of stirring at 200r / min, 0.93mmol of anhydrous indium trichloride and 9.3mmol of sodium acetate trihydrate were added to 31mL of ethylene glycol solution with a mass concentration of 87%, and after stirring evenly, the resulting mixture was transferred to a volume Put the polytetrafluoroethylene container into a 40mL polytetrafluoro container, then place the polytetrafluoro container in a stainless steel reaction kettle, and seal the kettle; the reaction kettle is kept at 190°C for 12 hours to obtain a reaction solution. The reaction solution was separated into solid and liquid, and the liquid was recovered; the solid was washed with water and alcohol, and dried at 60°C for 6 hours to obtain an ordered aggregate of indium oxyhydroxide nanorods (sample S-1).

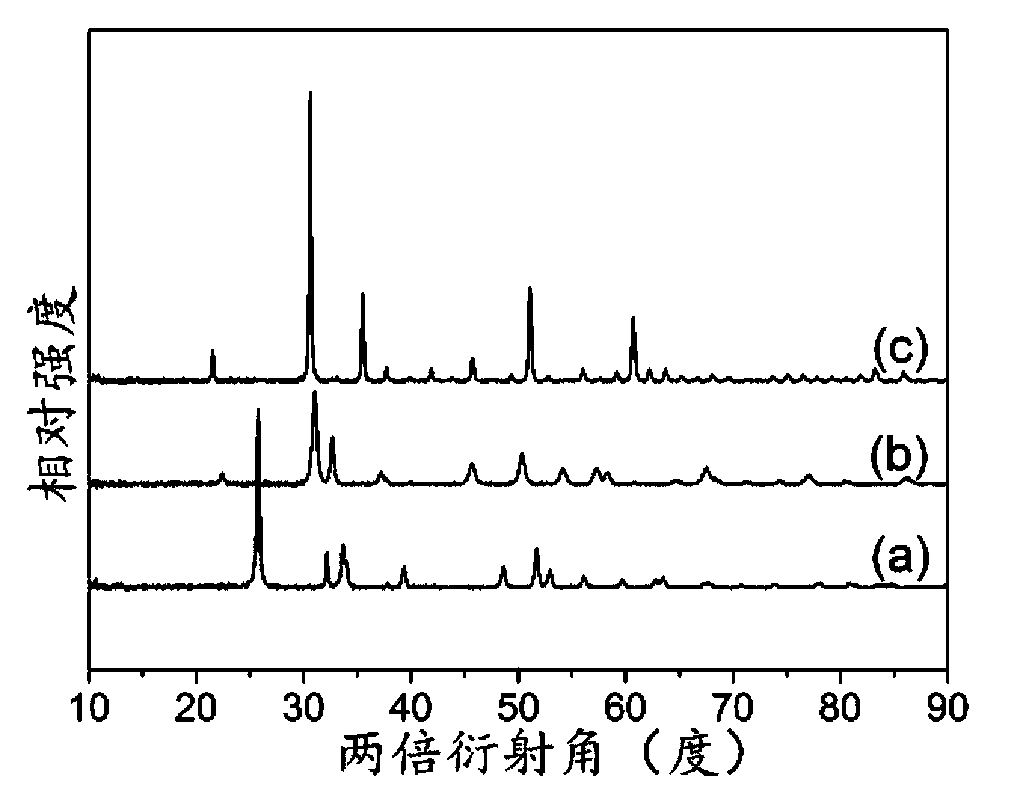

[0034] The XRD result of gained sample S-1 ( figure 1 , curve (a)) shows that sample S-1 is pure indi...

Embodiment 2

[0041] 1. Preparation of ordered aggregates of indium oxide oxyhydroxide (InOOH) nanorods

[0042] Under the condition of stirring at 400r / min, 6mmol indium trichloride tetrahydrate and 15mmol anhydrous sodium acetate were added to 31mL of ethylene glycol solution with a mass concentration of 77%. After stirring evenly, the resulting mixture was transferred to a volume of 40mL Put the polytetrafluoroethylene container in a stainless steel reaction kettle, seal the kettle; keep the reaction kettle at 220°C for 6 hours to obtain the reaction solution. The reaction solution was subjected to solid-liquid separation, and the liquid was recovered; the solid was washed with water and alcohol, and dried at 50°C for 10 hours to obtain ordered aggregates of indium oxide oxyhydroxide nanorods.

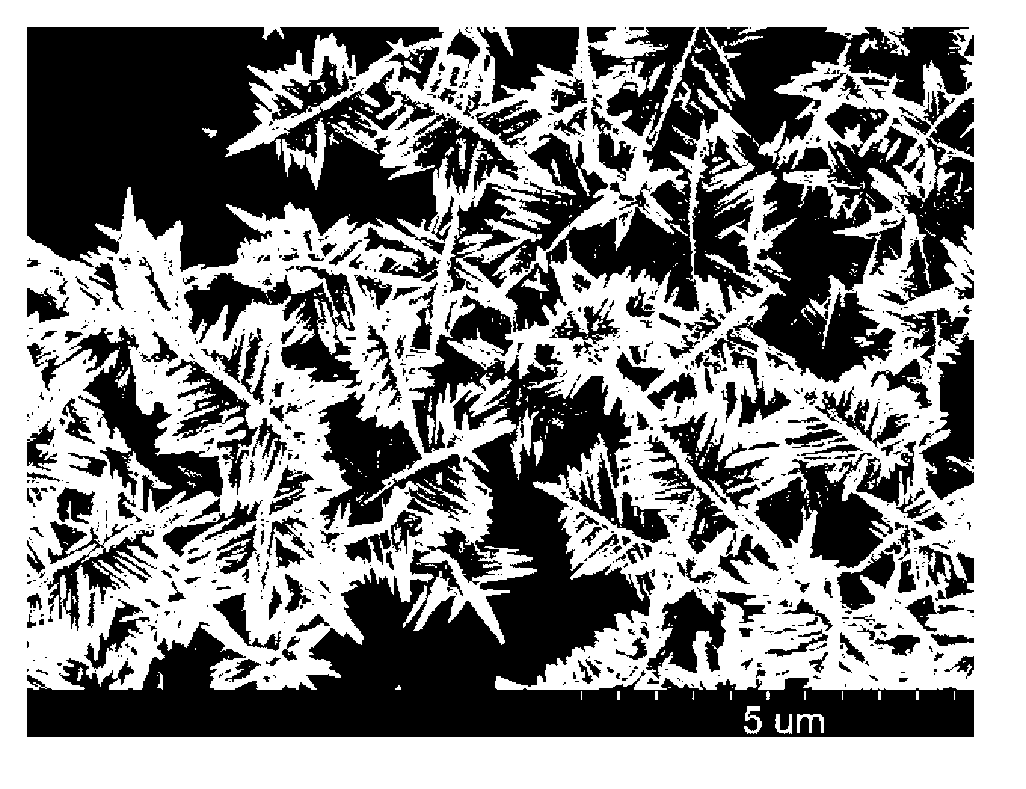

[0043] 2. Preparation of ordered aggregates of hexagonal indium oxide nanorods

[0044] The ordered aggregates of indium oxide oxyhydroxide nanorods prepared above were placed in a tube furnace,...

Embodiment 3

[0050] 1. Preparation of ordered aggregates of indium oxide oxyhydroxide (InOOH) nanorods

[0051] Under the condition of stirring at 300r / min, 2mmol of indium trichloride tetrahydrate and 13mmol of anhydrous sodium acetate were added to 31mL of ethylene glycol solution with a mass concentration of 84%. After stirring evenly, the resulting mixture was transferred to a volume of 40mL Put the polytetrafluoroethylene container in a stainless steel reaction kettle, seal the kettle; keep the reaction kettle at 200°C for 8 hours to obtain the reaction solution. The reaction solution was subjected to solid-liquid separation, and the liquid was recovered; the solid was washed with water and alcohol, and dried at 70° C. for 6 hours to obtain ordered aggregates of indium oxyhydroxide nanorods.

[0052] 2. Preparation of ordered aggregates of hexagonal indium oxide nanorods

[0053] The ordered aggregates of indium oxide oxyhydroxide nanorods prepared above were placed in a tube furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com