Integral type digestion tank

A septic tank and integrated technology, applied in the direction of biological sludge treatment, etc., can solve the problems of high labor intensity, easy leakage, and inconvenient use of workers, and achieve the effect of convenient sludge removal, environmental protection requirements, and improved purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

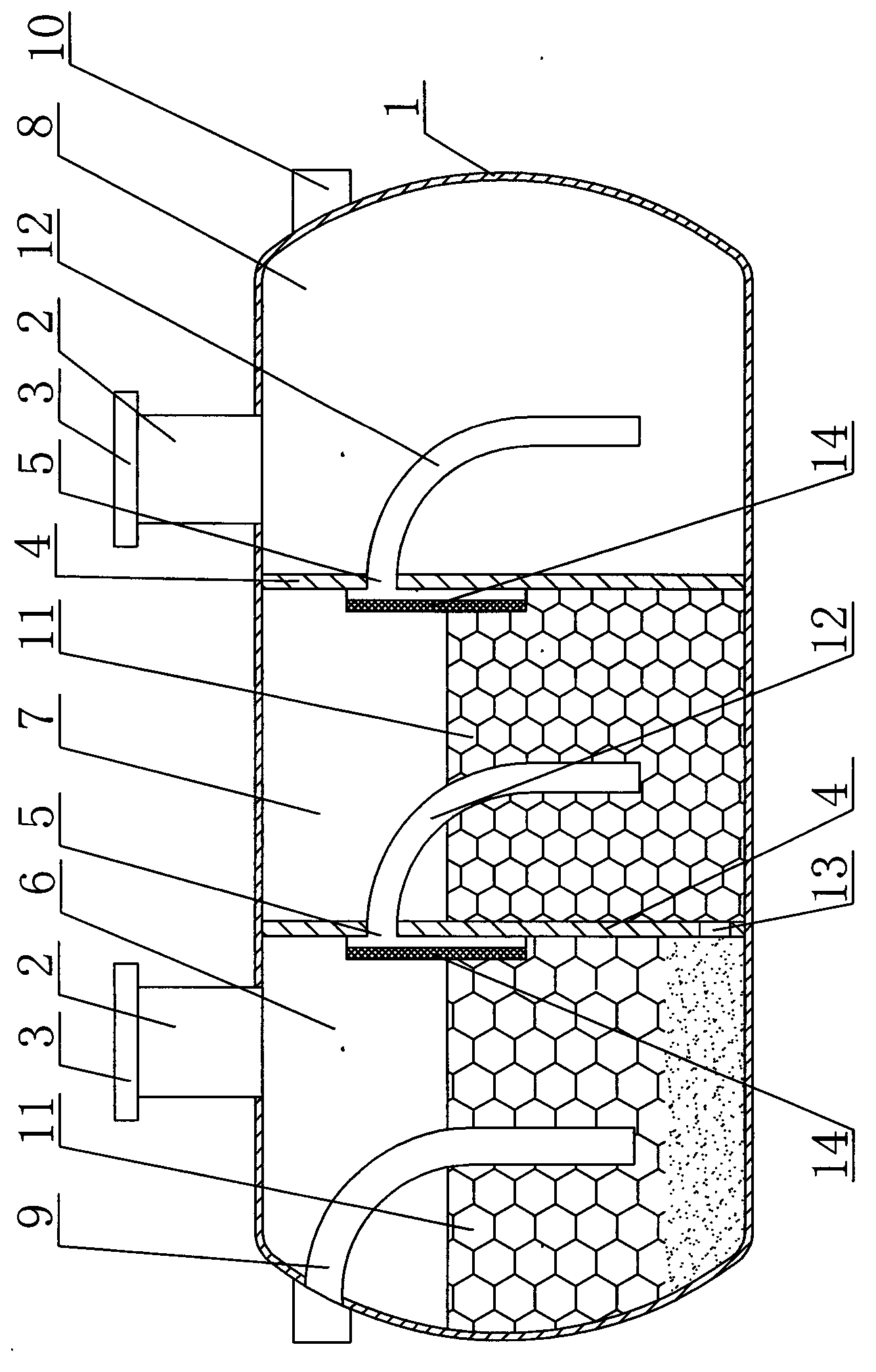

[0014] Embodiment: As shown in the accompanying drawings, an integral septic tank includes a casing 1, and the casing 1 is integrally made of tempered glass material, which avoids defects such as leakage and easy corrosion of traditional septic tanks, and prolongs the service life; A slag outlet 2 is provided on the top of the shell 1, and a slag outlet cover 3 is provided on the slag outlet 2. This structure is convenient for individuals to remove dirt and is easy to use.

[0015] Two partitions 4 are arranged in the shell 1, and the cavity of the shell 1 is divided into a primary anaerobic chamber 6, a secondary anaerobic chamber 7 and a clarification chamber 8 by the two partitions 4. On the upper part of the partition 4 All are provided with through holes 5, and the primary anaerobic chamber 6, the secondary anaerobic chamber 7 and the clarification chamber 8 communicate with each other through these through holes 5, which is convenient for graded filtration and has a good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com