Method for recycling mercury from mercury-containing solid wastes

A technology of solid waste and recovery method, applied in the direction of mercury halide and other directions, can solve the problems of low recovery rate, inconvenient operation, environmental pollution, etc., and achieve the effect of high recovery efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

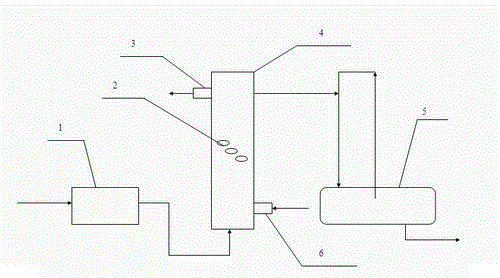

[0024] A method for recovering mercury in mercury-containing solid waste, including drying, chlorination, dry distillation, and absorption steps, 500Kg of mercury-containing solid waste 2 with a mercury content of 0.50% is loaded into a closed reactor 4, and the closed reactor 2 Heating, the heat transfer oil is introduced from the heat transfer oil inlet 6, and the heat transfer oil is discharged from the heat transfer oil outlet 3 after heating, and the N 2 Drying, control temperature 150°C, drying time 2 hours; turn off N 2 , into the above-mentioned dried mercury-containing solid waste 3, pass the dry Cl preheated by the preheater 1 2 , then raised to 250°C for 1 hour, then raised to 350°C for 2 hours; closed Cl 2 , N into the closed reactor 2 , the temperature was raised to 450°C for 2 hours, and then the temperature was raised to 550°C for 3 hours; the dry Cl that was preheated by the preheater 1 was passed into the above-mentioned dried mercury-containing solid waste ...

Embodiment 2

[0025] The difference between embodiment 2 and embodiment 1 is that the absorption process can use a spray device to absorb mercury chloride in the gas phase.

Embodiment 3

[0026] The difference between embodiment 3 and embodiment 1 or 2 is that a certain amount of dried Cl after being preheated by preheater 1 is passed into the closed reactor. 2 , and maintain a certain pressure, close the inlet and outlet of the airtight reactor, and do not need to open the power device of the circulating solvent storage tank 5 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com