Preparation method for 6-carboxylfluorescein

A technology of carboxyfluorescein and carboxyl group, applied in the field of preparation of 6-carboxyfluorescein, can solve problems such as large loss and low yield, and achieve the effects of reducing production cost, high application value, and simplifying purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

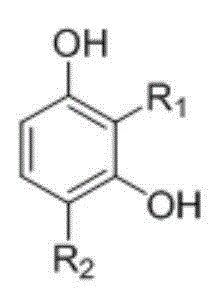

Method used

Image

Examples

Embodiment 1

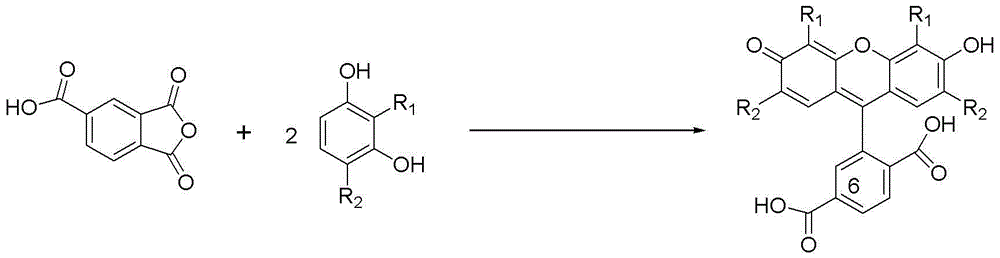

[0020]

[0021] a. Reaction steps:

[0022] At room temperature, in a reaction vessel, the resorcinol 2 (resorcinol, 57.2 g, 0.52 mol) dissolved in methanesulfonic acid (520 ml), added trimellitic anhydride 1 (1,2,4-Benzenetricarboxylic anhydride, 50 g, 0.26 mol), after stirring at room temperature for 10 minutes, tin tetrachloride (SnCl 4 , 6.1 ml, 0.055 mol), heated, and reacted at 90 ° C. After 6 hours, HPLC showed that the reaction was complete, and the reaction was stopped. The reaction system was cooled to room temperature to obtain a reaction solution;

[0023] b. Crystallization step

[0024] The reaction solution was poured into 4 liters of ice-water solution, stirred for 10 minutes, and the product precipitated out. Filter and dry, and the dried crude product is crystallized with methanol and hexane (methanol:hexane volume ratio is 1:4). Filter and dry to obtain 6-carboxyfluorescein methylsulfonic acid adduct.

[0025] c, hydrolysis step:

[0026] Add 6-ca...

Embodiment 2

[0031]

[0032] a. Reaction steps:

[0033] At room temperature, in a reaction vessel, 4-chlororesorcinol 3 (4-Chlororesorcinol, 75.2 g, 0.52 mol) dissolved in methanesulfonic acid (620 ml), adding trimellitic anhydride 1 (1,2,4-Benzenetricarboxylic anhydride, 50 g, 0.26 mol), after stirring at room temperature for 15 minutes, tin tetrachloride (SnCl 4 , 6.7 ml, 0.057 mol), heated, and reacted at 105 °C. After 6 hours, HPLC showed that the reaction was complete, and the reaction was stopped. The reaction system was cooled to room temperature to obtain a reaction solution;

[0034] b. Crystallization step

[0035] The reaction solution was poured into 4 liters of ice-water solution, stirred for 10 minutes, and the product precipitated out. Filter and dry, and the dried crude product is crystallized with methanol and hexane (methanol:hexane volume ratio is 1:4). Filter and dry to obtain 2',7'-dichloro-6-carboxyfluorescein methanesulfonic acid adduct.

[0036] c, hydrol...

Embodiment 3

[0042]

[0043] a. Reaction steps:

[0044] At room temperature, in a reaction vessel, 4-methylresorcinol 4 (4-methylresorcinol, 64.6 g, 0.52 mol) was dissolved in methanesulfonic acid (600 ml), and trimellitic anhydride was added 1 (1,2,4-Benzenetricarboxylic anhydride, 50 g, 0.26 mol), after stirring at room temperature for 10 minutes, tin tetrachloride (SnCl 4, 5.8 ml, 0.052 mol), heated, and reacted at 95 ° C. After 6 hours, HPLC showed that the reaction was complete, and the reaction was stopped. The reaction system was cooled to room temperature to obtain a reaction solution;

[0045] b. Crystallization step

[0046] The reaction solution was poured into 4 liters of ice-water solution, stirred for 10 minutes, and the product precipitated out. Filter and dry, and the dried crude product is crystallized with methanol and hexane (methanol:hexane volume ratio is 1:4). Filter and dry to obtain 2',7'-dimethyl-6-carboxyfluorescein methanesulfonic acid adduct.

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com