Oligomer compound, hydrophobic composition, preparation method of the oligomer compound, and use of the oligomer compound and the hydrophobic composition

A compound and composition technology, applied in oligomer compounds, hydrophobic compositions and their preparation and application fields, can solve the problem of unsuitable large-area hydrophobic surfaces and coatings, complex equipment or high-temperature calcination, and superhydrophobicity reduction And other problems, to achieve a significant effect of scrub resistance, improve the effect of waterproof and water-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

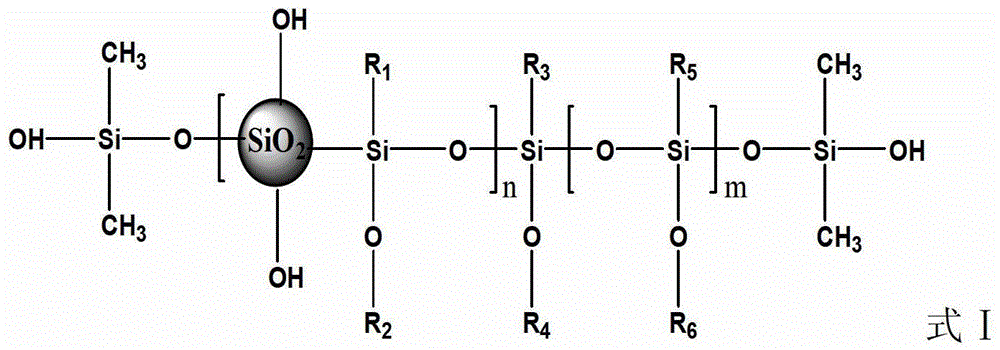

[0041] Example 1 Preparation of hydrophobic prepolymer compound

[0042]Dissolve 20 grams of ethyl orthosilicate in 150 grams of ethanol, add 1 gram of concentrated hydrochloric acid under full stirring, then add 10 grams of water dropwise, react at 80°C for 8 hours, and then distill off the water. The residual amount of concentrated hydrochloric acid was analyzed by titration, 5 g of concentrated hydrochloric acid was added, then 25 g of methyltrimethoxysilane was added, and the reaction was carried out at a temperature of 40 ° C for 2 hours, and then 50 g of methyltrimethoxysilane and perfluorooctane were added. 20 g of trimethoxysilane, 5 g of dimethyl hydroxychlorosilane was added after the condensation reaction at 70 ° C for 2 hours, and the end capping reaction was carried out. The reaction temperature was 45 ° C and the time was 1 hour; after the end capping reaction, carbonic acid was added. 5 g of sodium hydrogen is neutralized to pH 7, the solvent is distilled, then ...

Embodiment 2

[0046] Example 2 Preparation of Hydrophobic Prepolymer Compounds

[0047] Dissolve 40 grams of ethyl orthosilicate in 200 grams of ethanol, add 1.5 grams of concentrated hydrochloric acid under full stirring, then add 15 grams of water dropwise, react at 80°C for 8 hours, and then distill off the water. To analyze the residual amount of concentrated hydrochloric acid by titration, add 5 grams of concentrated hydrochloric acid, then add 60 grams of methyltrimethoxysilane, and react for 2 hours at a temperature of 40 °C, then add 150 grams of methyltrimethoxysilane and perfluorooctane. 60 g of trimethoxysilane, 15 g of dimethylhydroxychlorosilane was added after the condensation reaction at 70 °C for 2 hours, and the end-capping reaction was carried out. The reaction temperature was 45 °C and the time was 1 hour; after the end-capping reaction, carbonic acid was added. 15 g of sodium hydrogen was neutralized to pH 7, the solvent was distilled, then the unreacted material was was...

Embodiment 3

[0051] Example 3 Preparation of Hydrophobic Prepolymer Compounds

[0052] Dissolve 20 grams of ethyl orthosilicate in 200 grams of ethanol, add 1.5 grams of concentrated hydrochloric acid under full stirring, then add 15 grams of water dropwise, react at 80°C for 8 hours, and then distill off the water. To analyze the residual amount of concentrated hydrochloric acid by titration, add 5 g of concentrated hydrochloric acid, then add 60 g of methyltrimethoxysilane, react for 2 hours at a temperature of 40 °C, then add 350 g of hexadecyltrimethoxysilane and all 70 grams of fluorodecyl trimethoxysilane, 15 grams of dimethylhydroxychlorosilane was added after the condensation reaction at 70 ° C for 2 hours, and the end capping reaction was carried out. The reaction temperature was 45 ° C and the time was 1 hour; after the end capping reaction Add 15 g of sodium bicarbonate to neutralize to pH 7, distill the solvent, wash the unreacted material with ethanol and then layer, remove th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com