The preparation method of 2-ethyl methacrylate base benzyl phosphate

A technology of ethyl methacrylate-based benzyl phosphate and ethyl methacrylate-based dichlorophosphate, which is applied in the field of flame retardants, can solve the problems of high toxicity and low yield, and achieve improved purity and reduced Effects of production cost and shortened production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

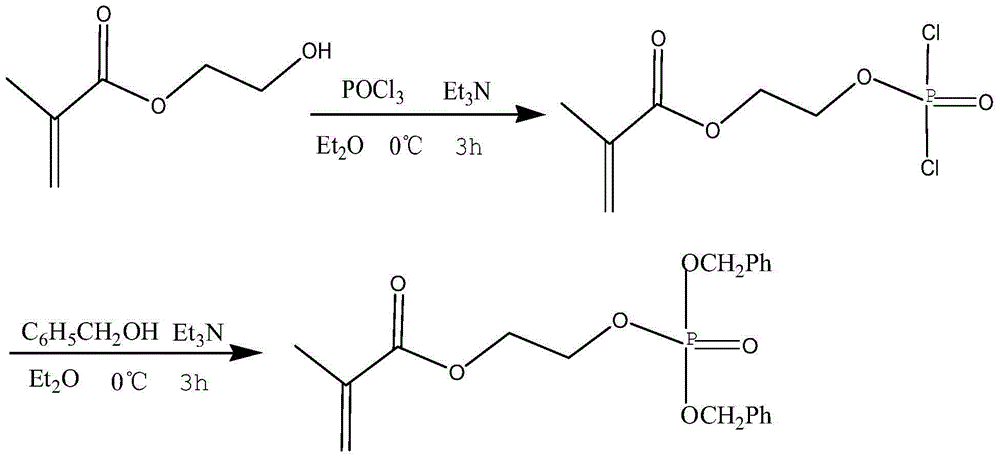

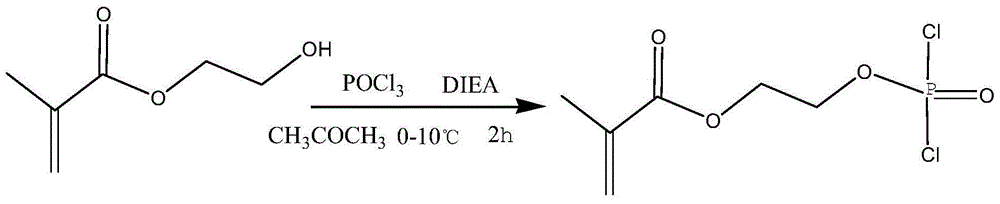

Method used

Image

Examples

Embodiment 1

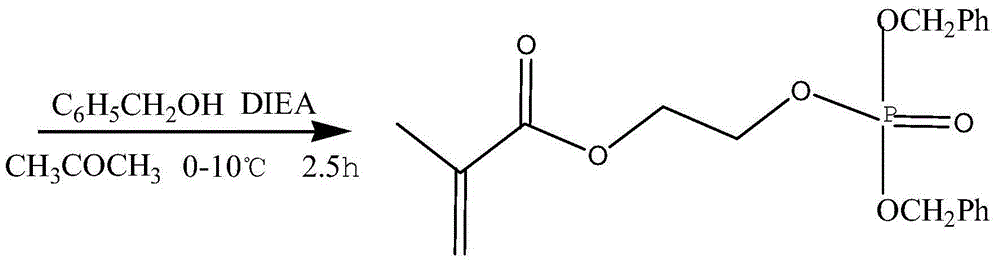

[0021] Dissolve 118g of hydroxyethyl methacrylate, 142g of phosphorus oxychloride, and 154g of DIEA in a three-necked flask added with 378g of acetone, and stir the reaction at 0-10°C for 2h; add 284g of benzyl alcohol and 286g of DIEA dropwise, The reaction was vigorously stirred for 2.5 h; left to stand overnight, filtered with suction, and the filtrate (clear) was rotary evaporated to remove the solvent to obtain a crude product. The yield of the product was 92% as measured by liquid phase mass spectrometry.

Embodiment 2

[0023] Dissolve 177g of hydroxyethyl methacrylate, 230g of phosphorus oxychloride, and 248g of DIEA in a three-necked flask with 585g of acetone, and stir for 2 hours at 0-10°C; add 461g of benzyl alcohol and 548g of DIEA dropwise, The reaction was vigorously stirred for 2.5 h; left to stand overnight, filtered with suction, and the filtrate (clear) was rotary evaporated to remove the solvent to obtain a crude product. The yield of the product was 93.1% as determined by liquid phase mass spectrometry.

Embodiment 3

[0025] Dissolve 270g of hydroxyethyl methacrylate, 378g of phosphorus oxychloride, and 386g of DIEA in a three-necked flask added with 950g of acetone, and stir at 0-10°C for 2 hours; add 648g of benzyl alcohol and 681g of DIEA dropwise, The reaction was vigorously stirred for 2.5 h; left to stand overnight, suction filtered, and the filtrate (clear) was rotovapped to remove the solvent to obtain a crude product. The yield of the product was 93.4% as determined by liquid phase mass spectrometry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com