Rare earth polyacid, organic light active molecule and layered double hydroxides composite luminous thin film and preparation method thereof

A kind of photoactive molecule, rare earth polyacid technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

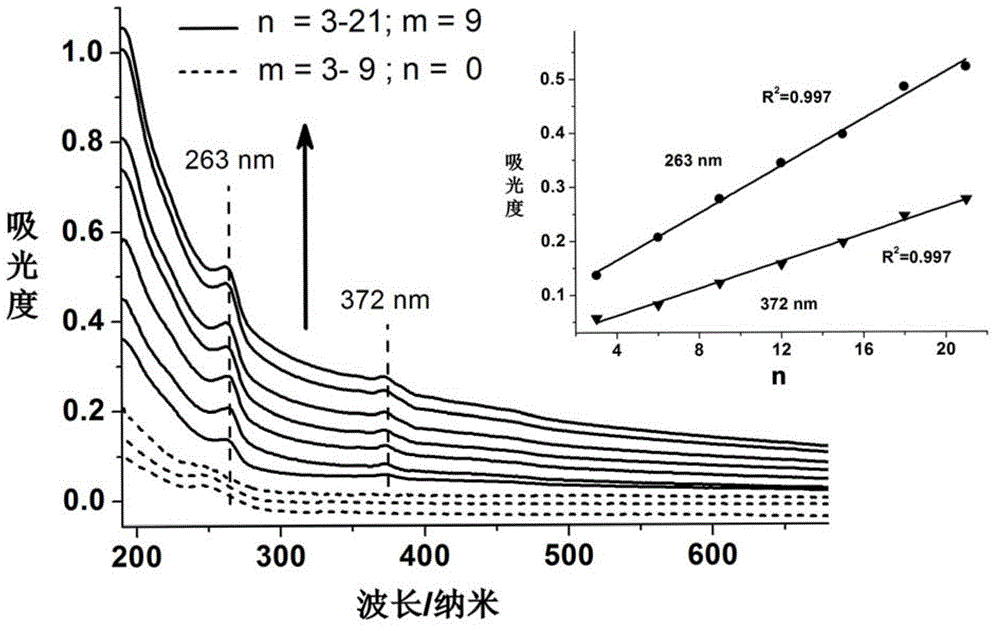

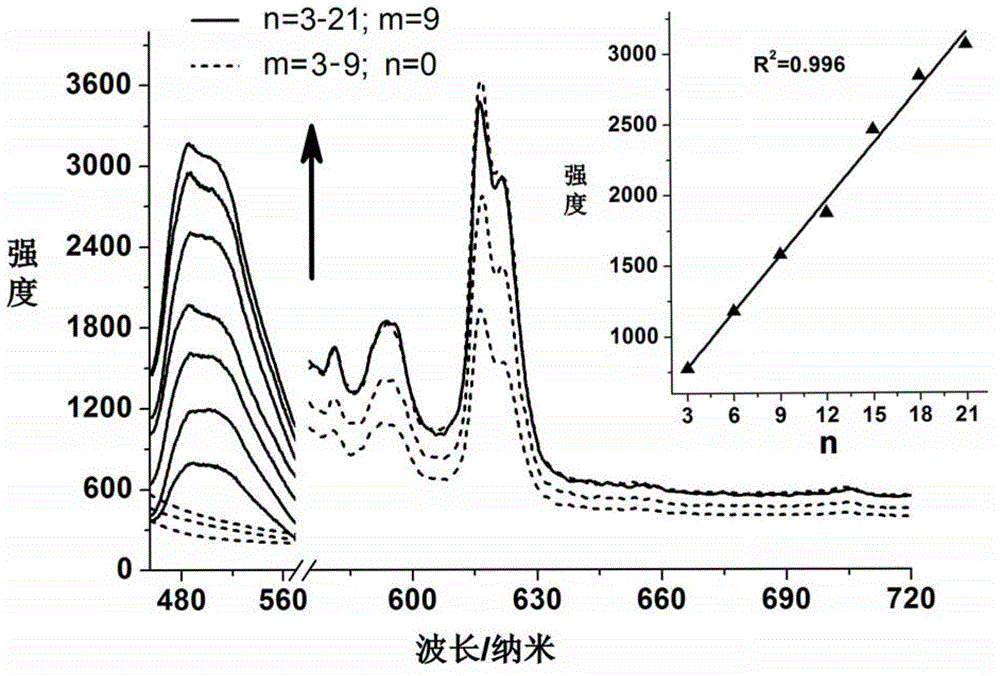

Image

Examples

Embodiment 1

[0029] 1. Preparation of hydrotalcite precursor with nitrate between layers by ion exchange method:

[0030] a, 0.02mol (5.13g) of solid Mg (NO 3 ) 2 ·6H 2 O and 0.01mol (3.75g) of solid Al(NO 3 ) 3 9H 2 O, and 0.026mol (3.645g) of solid hexamethylenetetramine (HMT) were dissolved in 80ml of water, then the mixed solution was placed in a reaction kettle, reacted at 140°C for 24h, then suction filtered, and washed with a large amount of deionized water Washing, and finally drying in an oven at 100°C, to obtain magnesium aluminum carbonate intercalated hydrotalcite Mg 2 Al-CO 3 -LDH.

[0031] b, 1mol (85g) of solid NaNO 3 Dissolve in 1000ml of water, add 3.3mmol (0.236ml) of concentrated nitric acid, and finally add 1.0g of the above Mg 2 Al-CO 3 -LDH sample was added to the reaction vessel, stirred vigorously under the protection of nitrogen, reacted at room temperature for 48 hours, filtered with suction, washed with a large amount of deionized water, and dried in va...

Embodiment 2

[0038] Repeat steps (1)-(5) of Example 1;

[0039] (6) Blow dry the treated substrate with nitrogen, immerse in solution A for 10 minutes, soak in deionized water for 2 minutes, blow dry with nitrogen, then immerse in solution B for 10 minutes, soak in deionized water for 2 minutes, use Blow dry with nitrogen to obtain 1 layer of (EuW 10 / LDH)UTF, then alternately immersed in solution A and solution C, repeated twice to obtain [(EuW 10 / LDH) 1 / (BNMAPVS / LDH) 2 ] 1 UTFs (the cycle once can be abbreviated as (EuW 10 / LDH) 1 / (BNMAPVS / LDH) 2 UTFs). Repeat the above steps x times to get [(EuW 10 / LDH) 1 / (BNMAPVS / LDH) 2 ] x UTFs (x=1-10).

Embodiment 3

[0041] Repeat steps (1)-(5) of Example 1;

[0042] (6) Blow dry the treated substrate with nitrogen, soak in solution A for 10 minutes, soak in deionized water for 2 minutes, blow dry with nitrogen, then immerse in solution B for 10 minutes, soak in deionized water for 2 minutes, Blow dry with nitrogen, repeat this step twice to get (EuW 10 / LDH) 2 UTFs. Then alternately immerse in solution A and solution C to obtain (EuW 10 / LDH) 2 / (BNMAPVS / LDH) 1 UTFs. Repeat the above steps x times to get [(EuW 10 / LDH) 2 / (BNMAPVS / LDH) 1 ] x UTFs (x=1-10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com