Environment-friendly rust-removing anti-rust agent

A rust inhibitor and environmentally friendly technology, applied in the direction of metal material coating process, can solve the problems of workers' health and environmental pollution, and achieve the effect of convenient rust removal, rust prevention and easy removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

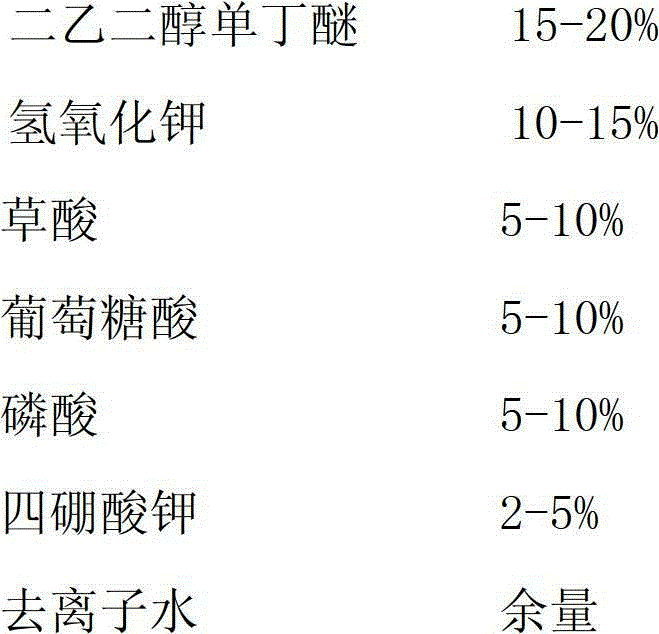

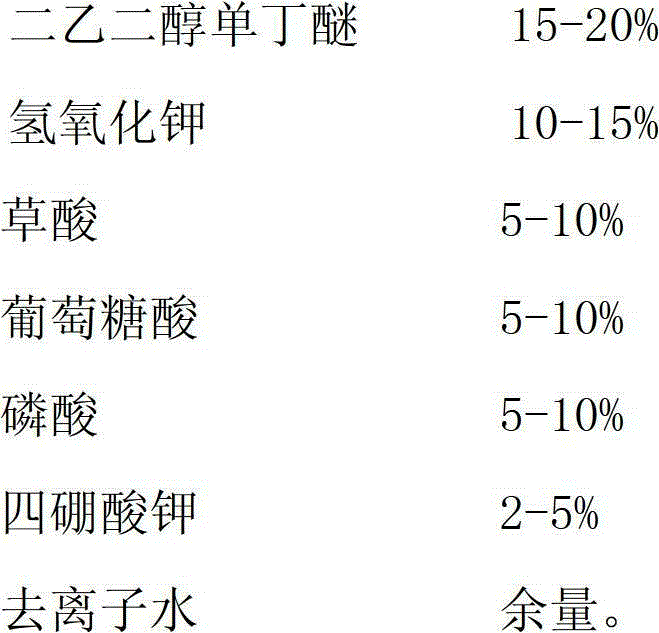

Embodiment 1

[0019] Weigh 15kg of diethylene glycol monobutyl ether, 13kg of potassium hydroxide, 10kg of oxalic acid, 5kg of gluconic acid, 5kg of phosphoric acid, and 2kg of potassium tetraborate, add them in sequence to 50kg of deionized water, heat to 50-60°C and stir until all the ingredients Dissolve completely until there is no sediment at the bottom of the container, pack after cooling.

Embodiment 2

[0021] Weigh 16kg of diethylene glycol monobutyl ether, 12kg of potassium hydroxide, 6kg of oxalic acid, 6kg of gluconic acid, 6kg of phosphoric acid, and 3kg of potassium tetraborate, add in sequence 51kg of deionized water, heat to 50-60°C and stir until all ingredients Dissolve completely until there is no sediment at the bottom of the container, pack after cooling.

Embodiment 3

[0023] Weigh 17kg of diethylene glycol monobutyl ether, 13kg of potassium hydroxide, 7kg of oxalic acid, 10kg of gluconic acid, 5kg of phosphoric acid, and 2kg of potassium tetraborate, add in sequence 46kg of deionized water, heat to 50-60°C and stir until all ingredients Dissolve completely until there is no sediment at the bottom of the container, pack after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com