Method for preparing MWNT (Multi-Walled Carbon Nanotube) modified paper-based friction material

A multi-walled carbon nanotube, paper-based friction material technology, applied in chemical instruments and methods, synthetic cellulose/non-cellulose material pulp/paper, paper, etc., can solve the material failure, the performance degradation of multi-layer carbon nanotubes , easy delamination and other problems, to achieve the effect of low wear rate, stable friction performance, and improved friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Take 0.7g of cashew nut shell modified phenolic resin, dissolve it in 150ml of absolute ethanol to obtain a phenolic resin solution, wait for the phenolic resin to fully dissolve and let it stand for 20 hours, seal it and store it to obtain A solution;

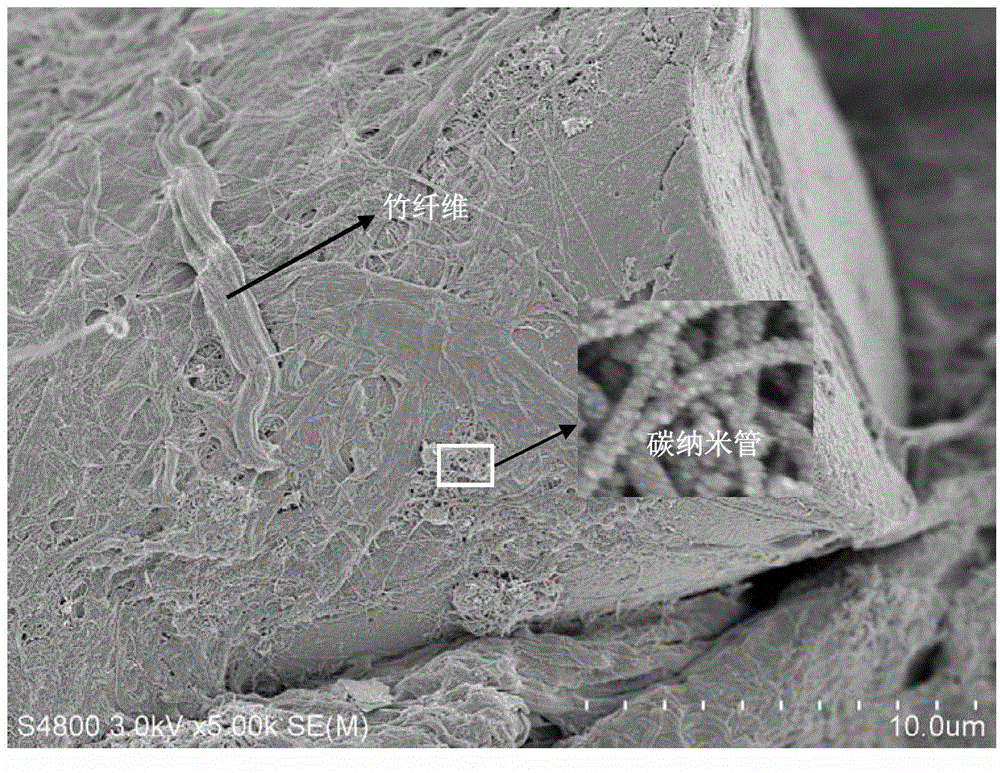

[0019] Step 2: Disperse 0.5g of multi-walled carbon nanotubes with a diameter of 30-50nm in 100ml of 0.1% sodium dodecylsulfonate (SDS) aqueous solution, and magnetically stir for 4 hours to configure uniformly dispersed carbon nanotubes Suspension B;

[0020] Step 3: Take 6g of chopped carbon fibers with a diameter of 8-15 μm, 5g of bamboo fibers with a beating degree of 75°SR, 1g of diatomaceous earth, and water that can completely disperse the above raw materials, disperse them in water to obtain a mixed solution, and then Get 80g of suspoemulsion B and pour into the mixed solution to obtain C solution;

[0021] Step 4: Pour the C solution into the decomposer and disperse it for 800r, take out the decomposed...

Embodiment 2

[0024] Step 1: Take 1.2g of cashew nut shell modified phenolic resin, dissolve it in 150ml of absolute ethanol to obtain a phenolic resin solution, wait until the phenolic resin is fully dissolved, let it stand for 24 hours, seal it and save it, and obtain A solution;

[0025] Step 2: Disperse 1 g of multi-walled carbon nanotubes with a diameter of 30-50 nm in 170 ml of 0.2% sodium dodecylsulfonate (SDS) aqueous solution, and stir magnetically for 5 hours to prepare a uniformly dispersed carbon nanotube suspension Liquid B;

[0026] Step 3: Take 8g of chopped carbon fiber with a diameter of 8-15 μm, 7g of bamboo fiber with a beating degree of 78°SR, 1.5g of diatomaceous earth and water that can completely disperse the above raw materials, disperse it in water to obtain a mixed solution, and then Take 100g of suspoemulsion B and pour it into the mixed solution to obtain C solution;

[0027] Step 4: Pour the C solution into the decomposer and disperse for 1000r, take out the de...

Embodiment 3

[0030] Step 1: Take 2.25g of cashew nut shell modified phenolic resin, dissolve it in 150ml of absolute ethanol to obtain a phenolic resin solution, wait until the phenolic resin is fully dissolved, let it stand for 26 hours, seal it and save it, and obtain A solution;

[0031] Step 2: Disperse 2.5g of multi-walled carbon nanotubes with a diameter of 30-50nm in 250ml of 0.3% sodium dodecylsulfonate (SDS) aqueous solution, and magnetically stir for 5.5 hours to prepare uniformly dispersed carbon nanotubes Suspension B;

[0032] Step 3: Take 10g of chopped carbon fiber with a diameter of 8-15 μm, 9g of bamboo fiber with a beating degree of 80°SR, 2.5g of diatomaceous earth and water that can completely disperse the above raw materials, disperse it in water to obtain a mixed solution, and then Then get 200g suspoemulsion B and pour into the mixed solution to obtain C solution;

[0033] Step 4: Pour the C solution into the deconcentrator and disperse for 1500r, take out the C sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com