Motor train unit bogie disintegration flow line maintenance system and maintenance method thereof

A technology for bogies and EMUs, applied to liquid cleaning methods, chemical instruments and methods, cleaning methods and appliances, etc., which can solve problems such as high labor intensity, disorderly maintenance, illegal repairs, and missing repairs, and reduce Labor intensity, efficient maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

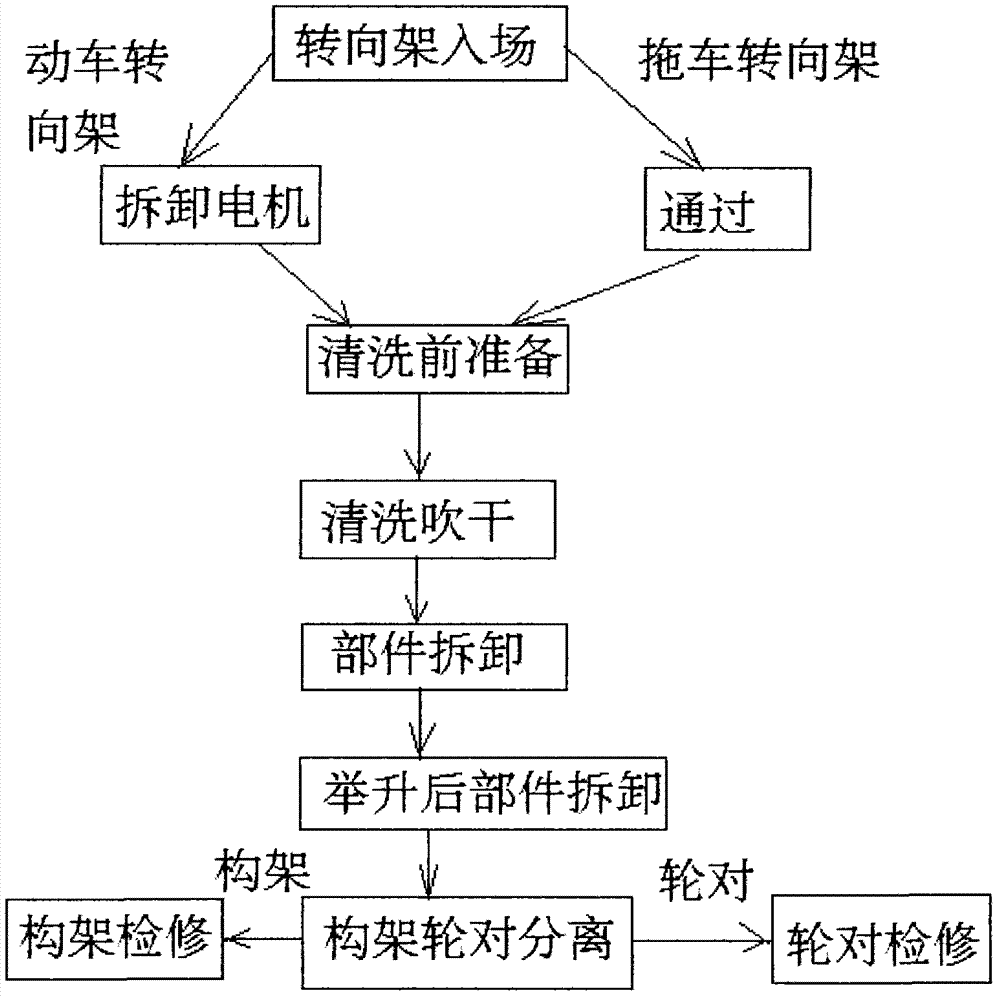

[0039] Such as figure 1 As shown, the method for dismantling and repairing the bogie of the EMU of the present invention comprises the following steps:

[0040] 1. Motor disassembly and maintenance

[0041] Bogie entry: The bogie disassembled from the EMU enters the field, and enters the bogie dismantling assembly line to stay. At this station, the bogie receipt operation is performed first. The bogie receipt program is downloaded from the "EMU Management Information System" for repair. Vehicle plan, retrieve the latest loading records of the bogie, and list the information of the front and rear bogies on the computer screen, including the bogie number, etc. At the same time, you can view the historical inspection records of the bogie. After manual verification, file the bogie. If it is the first overhaul, take 3 ID cards from the ID card box, and the card reader reads 3 cards respectively, as the identification ID cards of the frame, front and rear motors, and magnetically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com